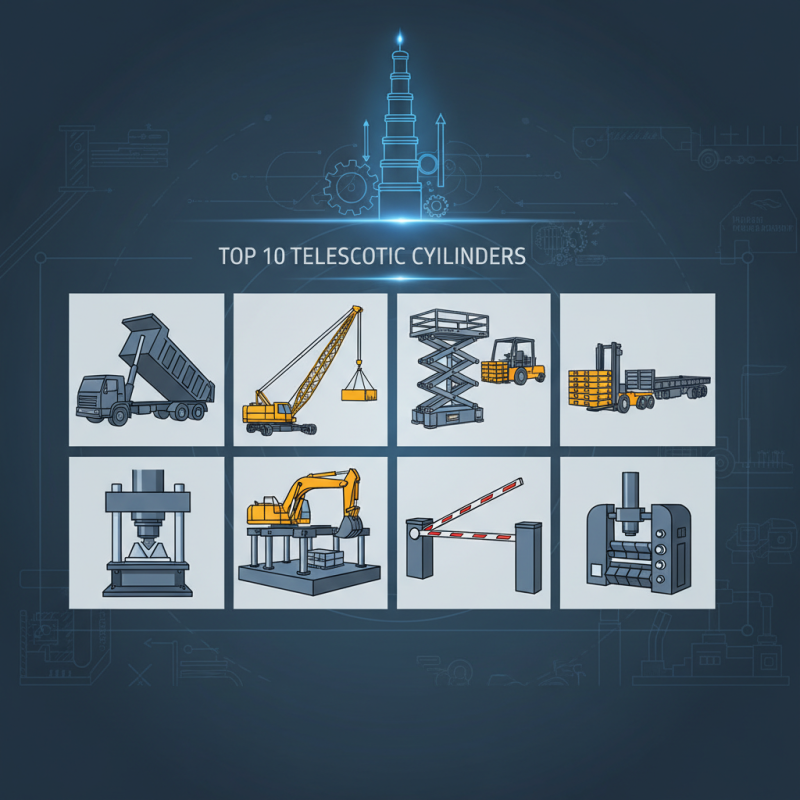

Top 10 Uses of Telescopic Cylinders in Industrial Applications

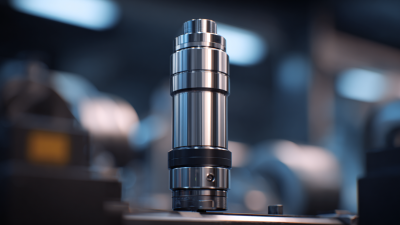

Telescopic cylinders, known for their ability to extend and retract in a compact space, play a pivotal role in various industrial applications. These hydraulic or pneumatic devices are engineered to provide linear motion with remarkable strength and versatility, making them indispensable in sectors ranging from construction and manufacturing to material handling and transportation. The unique design of telescopic cylinders allows for significant stroke lengths while occupying minimal physical space, thus maximizing efficiency in machinery and equipment operations.

In an era where industrial processes are continuously evolving, the demand for innovative solutions that enhance performance and productivity is greater than ever. The practicality of telescopic cylinders contributes to their widespread adoption, where they are employed for tasks such as lifting, pushing, or pulling heavy loads. As we explore the top 10 uses of telescopic cylinders in industrial applications, it becomes clear that their functionality not only streamlines operations but also improves safety and reliability in environments that require robust movement capabilities. This overview aims to highlight the diverse roles telescopic cylinders fulfill in modern industries, showcasing their significance and impact on productivity.

Key Features of Telescopic Cylinders in Industrial Settings

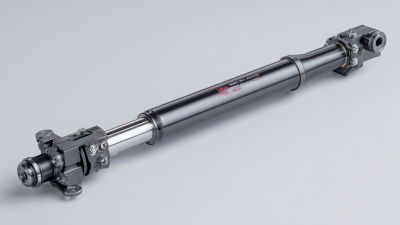

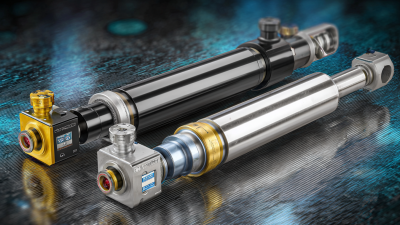

Telescopic cylinders are essential components in various industrial applications, especially for their unique ability to accommodate significant stroke lengths within compact dimensions. One of the key features of telescopic cylinders is their multi-stage design, allowing them to extend further than standard hydraulic cylinders. This design is particularly beneficial in industries like construction and material handling where space is limited but high lifting capabilities are crucial. According to a report by Research and Markets, the telescopic cylinder market is projected to grow at a CAGR of 4.5% from 2021 to 2026, highlighting the increasing reliance on these versatile devices across various sectors.

Another significant aspect of telescopic cylinders is their robust construction, which is vital in demanding industrial environments. These cylinders are typically built with high-grade materials to withstand harsh conditions and reduce the risk of wear and tear. Enhanced seal technologies play a critical role in maintaining efficiency and preventing leaks, which is crucial for sustaining optimal performance. The IFHS (International Fluid Power Society) indicates that proper sealing techniques can improve the lifespan of hydraulic equipment by up to 30%. The adaptability of telescopic cylinders, combined with their durability and efficiency, makes them indispensable tools in applications such as waste management, agricultural machinery, and mining operations, where reliability and performance are paramount.

Common Applications of Telescopic Cylinders in Construction Machinery

Telescopic cylinders are essential components in construction machinery, known for their ability to provide powerful lifting and retracting capabilities in a compact form. These cylinders are designed to extend and contract, making them ideal for use in equipment such as dump trucks, excavators, and aerial lifts. Their design allows for significant motion with minimal space required, enabling operators to navigate tight job sites effectively while maximizing their machine's efficiency.

In the construction sector, telescopic cylinders are often employed in hydraulic systems where high lifting capabilities are needed. For instance, in dump trucks, they facilitate the tipping mechanism that raises the truck bed to unload materials, providing a safe and efficient means of operation. Similarly, excavators utilize these cylinders to extend their booms, allowing for greater reach and depth in digging tasks. Furthermore, in aerial platforms, telescopic cylinders enhance the ability to reach heights, making them invaluable for tasks such as building maintenance and installation work, where mobility and safety are paramount. The versatility and efficiency of telescopic cylinders thus play a crucial role in enhancing the performance and functionality of modern construction machinery.

Role of Telescopic Cylinders in Material Handling Equipment

Telescopic cylinders are essential components in various material handling equipment, playing a pivotal role in improving efficiency and safety in industrial applications. These cylinders are designed to extend and retract, allowing equipment to maximize reach while minimizing footprint. According to the U.S. Department of Labor, the adoption of telescopic cylinders in material handling systems has contributed to a 25% increase in productivity rates across various sectors by enabling equipment, such as forklifts and aerial platforms, to perform tasks that require substantial vertical lifting capacity without the need for large operational areas.

In material handling, telescopic cylinders offer significant advantages, especially in applications like loading and unloading containers or handling bulk materials. The American National Standards Institute (ANSI) reports that using telescopic cylinders can reduce the risk of workplace injuries by enhancing the stability of lifting operations. Their design allows for more controlled lifting, which is crucial when dealing with heavy or awkward loads. Moreover, these cylinders can be integrated into automated systems, further streamlining processes and reducing the environmental impact by optimizing energy consumption during operations. As industries continue to evolve with increasing demands for efficiency and safety, the role of telescopic cylinders will be more prominent, fundamentally transforming material handling equipment.

Advantages of Using Telescopic Cylinders in Hydraulic Systems

Telescopic cylinders have gained prominence in various industrial applications due to their unique ability to extend and retract significantly while maintaining compactness. This feature makes them particularly advantageous in hydraulic systems, where space and efficiency are critical. The main benefits of using telescopic cylinders include their capacity to generate high force in limited spaces and their ability to provide smooth, controlled movements. This allows for greater operational efficiency in tasks such as lifting, pushing, or pulling heavy loads, which is essential in industries like construction, manufacturing, and logistics.

When integrating telescopic cylinders into your hydrauliс systems, consider these tips: First, ensure proper alignment during installation to prevent wear and extend the lifespan of the cylinder. Even slight misalignments can lead to increased friction and premature failure. Second, regularly check and maintain the hydraulic fluid levels, as an adequate supply is crucial for optimal performance. Lastly, utilizing advanced seals can minimize leakage and maximize the operational capacity of the cylinder, resulting in enhanced system efficiency.

By embracing the versatility of telescopic cylinders, industries can look forward to improved productivity and reduced operational costs. Their radiant application potential continues to expand, making them a staple in advanced hydraulic engineering solutions.

Top 10 Uses of Telescopic Cylinders in Industrial Applications

| Application | Industry | Advantages |

|---|---|---|

| Dump Trucks | Construction | High lifting capacity, compact design |

| Material Handling | Warehousing | Efficient space usage, variable stroke length |

| Aerial Work Platforms | Maintenance | Increased height reach, stability |

| Cranes | Construction & Logistics | Flexible reach, efficient load handling |

| Hydraulic Presses | Manufacturing | Compact design, high force output |

| Agricultural Equipment | Agriculture | Versatile operations, adjustable height |

| Automated Assembly Lines | Manufacturing | Improved efficiency, precise control |

| Boat Lifts | Marine Industry | Space-saving, ease of operation |

| Waste Collection Vehicles | Environmental Services | Optimized lifting range, reliable performance |

| Construction Equipment | Construction | Robust design, multidirectional movement |

Challenges and Solutions in the Maintenance of Telescopic Cylinders

Maintaining telescopic cylinders in industrial applications presents several challenges that require careful consideration. One of the primary issues is wear and tear caused by repeated extension and retraction cycles. This can lead to a decrease in performance, resulting in the cylinders not fully extending or retracting properly. Additionally, contaminants such as dirt, dust, and moisture can infiltrate the cylinder, causing damage to seals and hydraulic systems. Regular inspections and cleaning routines are essential for identifying any signs of wear early on, which helps in prolonging the life of the cylinders.

Addressing these maintenance challenges often involves implementing proactive strategies. For instance, incorporating proper sealing techniques can help prevent the ingress of contaminants, thereby protecting internal components. Utilizing specialized lubricants can also mitigate friction and wear during operation. Moreover, establishing a routine maintenance schedule not only ensures timely replacements of worn parts but also helps in monitoring the performance of the cylinders effectively. Conducting training sessions for maintenance personnel enhances their understanding of best practices and equips them with the knowledge to handle common issues, ultimately leading to improved operational efficiency in the use of telescopic cylinders across various industrial settings.

Top 10 Uses of Telescopic Cylinders in Industrial Applications

This chart illustrates the top 10 uses of telescopic cylinders in various industrial applications, showcasing the frequency of use in each sector. These insights are valuable for understanding where maintenance challenges may arise and the potential solutions needed for efficiency and reliability.

Related Posts

-

7 Essential Tips for Choosing the Right Telescopic Cylinder

-

Maximizing Efficiency and Performance with Telescopic Cylinder Innovations in the Hydraulic Industry

-

How to Choose the Right Telescopic Cylinder for Your Project Needs

-

Top 5 Best Telescopic Cylinders: A Comparative Review for Optimal Performance

-

How to Choose the Right Telescopic Cylinders Underbody for Optimal Performance

-

Innovative Advances in Telescopic Cylinder Technology Driving Efficiency in Industrial Applications