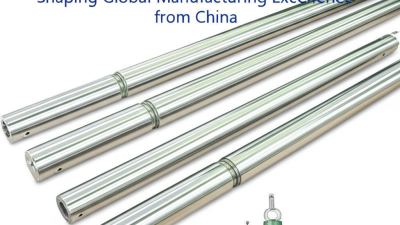

Unmatched Quality in Telescopic Cylinders Shaping Global Manufacturing Excellence from China

In the realm of global manufacturing, the integration of advanced technology and unwavering quality has propelled certain products to unmatched standards. One such product, the Telescopic Cylinder, epitomizes this evolution, particularly within the expansive industrial landscape of China. As manufacturers seek to enhance their operational efficiency and performance, the Telescopic Cylinder emerges as a pivotal component, designed not only for durability but also for versatility across various applications. This blog delves into the remarkable qualities of Telescopic Cylinders, exploring how they are not only meeting but exceeding global industry benchmarks. By combining cutting-edge engineering with best practices in manufacturing, China is setting a new precedent in the production of these critical components, ensuring their position at the forefront of innovation and excellence in the global market.

The Rise of Chinese Telescopic Cylinders in the Global Market: Key Data Insights

The global hydraulic cylinder market is experiencing substantial growth, with its revenue projected to surge from USD 14.3 billion in 2021 to an impressive USD 18.3 billion by 2027. This surge reflects the rising demand for hydraulic systems across various sectors, including construction, manufacturing, and agriculture. Amid this growth, Chinese manufacturers are emerging as dominant players, leveraging advanced technology and competitive pricing to enhance their presence in the international market.

As the demand for hydraulic cylinders escalates, Chinese telescopic cylinders are becoming increasingly vital in global manufacturing. Their superior design, efficiency, and reliability are reshaping industry standards and driving innovations. This shift not only highlights China's manufacturing capabilities but also underscores the country's strategic focus on enhancing product quality and supply chain optimization. The combination of aggressive pricing and unmatched quality positions Chinese telescopic cylinders as a pivotal force in the global hydraulic cylinder landscape, catering to diverse industries and contributing to the evolution of manufacturing excellence worldwide.

Unpacking the Manufacturing Processes Behind High-Quality Telescopic Cylinders

In the evolving landscape of global manufacturing, the production of telescopic cylinders has emerged as a hallmark of excellence, particularly in China. The manufacturing processes behind these high-quality components involve a combination of advanced technology and rigorous quality control measures. Precision engineering is vital, as each cylinder must meet stringent specifications to ensure efficiency and durability within hydraulic systems. Engineers utilize state-of-the-art machinery and materials, translating innovative designs into functional products that cater to the expanding market.

**Tip:** When selecting telescopic cylinders for your operations, consider the background and capabilities of the manufacturer. A reliable company should demonstrate a track record of quality assurance and innovative practices.

Furthermore, the integration of automation in the manufacturing process not only enhances production speed but also minimizes human error. This evolution toward smart manufacturing is transforming how telescopic cylinders are made, positioning suppliers to better meet the increasing global demand.

**Tip:** Always look for certifications and compliance with industry standards when sourcing telescopic cylinders, as this ensures product reliability and performance.

Unmatched Quality in Telescopic Cylinders Shaping Global Manufacturing Excellence from China

| Dimension (mm) | Material Type | Pressure Rating (MPa) | Surface Treatment | Manufacturing Process |

|---|---|---|---|---|

| 50 x 100 | Carbon Steel | 16 | Zinc Plated | CNC Machining |

| 60 x 120 | Alloy Steel | 20 | Anodized | Hydraulic Forming |

| 70 x 150 | Stainless Steel | 25 | Powder Coated | Welding Fabrication |

| 80 x 200 | Aluminum Alloy | 30 | Chromate Conversion | Extrusion |

Innovative Materials and Technologies Driving the Excellence of Telescopic Cylinder Production

In the competitive landscape of global manufacturing, telescopic cylinders have emerged as a hallmark of quality and innovation, particularly from China. The use of advanced materials coupled with cutting-edge technologies has propelled the production of these cylinders to unrivaled standards. High-strength alloys and composite materials not only enhance durability but also reduce weight and improve efficiency. This push for innovation is not merely about meeting operational needs; it's about setting new benchmarks in the industry.

When considering the purchase of telescopic cylinders, it’s essential to prioritize manufacturers who emphasize research and development. Look for companies that utilize the latest simulation technologies during the design phase to ensure optimal performance under various working conditions. Additionally, pay attention to their testing methodologies; rigorous quality control processes are a sign of commitment to excellence.

Tip: Always request detailed specifications and case studies from potential suppliers to understand their caliber in real-world applications. Furthermore, consider the long-term implications of material choices; investing in high-quality, innovative materials can lead to reduced maintenance costs and increased lifespan for your telescopic cylinders.

Market Trends: How Telescopic Cylinders Are Revolutionizing Various Industries

In recent years, telescopic cylinders have emerged as pivotal components transforming various sectors, from construction to materials handling. According to a report by Research and Markets, the global telescopic cylinder market is anticipated to grow by over 3% annually, driven by increasing demand for efficient lifting solutions in industries such as mining and waste management. This growth reflects a broader trend where businesses prioritize equipment that enhances operational efficiency while minimizing space constraints.

As industries strive for innovation, the versatility of telescopic cylinders plays a crucial role. With their ability to extend and retract mechanisms, these cylinders optimize the way machinery operates in limited spaces. A study featured in the Journal of Manufacturing Science highlights that adopting advanced telescopic systems can improve productivity by as much as 25%. For manufacturers, investing in this technology not only aligns with sustainability goals but also offers significant cost savings through enhanced performance.

**Tips:** When selecting telescopic cylinders, always consider the working pressure and environment, as these factors can significantly influence performance. Additionally, regular maintenance checks can prolong the life of hydraulic systems, ensuring consistent operation without unexpected downtimes. Moreover, collaborating with reputable manufacturers ensures that you acquire high-quality components that comply with industry standards.

Impact of Telescopic Cylinders on Different Industries

This chart illustrates the impact of telescopic cylinders across various industries, highlighting the growth potential and adoption rates that are shaping global manufacturing excellence.

Sustainability in Manufacturing: Eco-Friendly Practices in Telescopic Cylinder Production

The production of telescopic cylinders is advancing through innovative manufacturing practices that prioritize sustainability. Eco-friendly approaches are increasingly being integrated into the manufacturing process to reduce environmental impact, aligning with global trends towards greener production. Utilizing laser-based technologies, manufacturers can enhance precision and efficiency while minimizing waste. Such advancements allow for the creation of high-quality products with a lower carbon footprint.

Moreover, the implementation of advanced materials and innovative designs contributes to a more sustainable manufacturing environment. By focusing on renewable resources and energy-efficient production techniques, companies can lead the way in eco-friendly practices within the telescopic cylinder industry. The fusion of cutting-edge technology with sustainable practices not only improves the quality of products but also sets a benchmark for industry standards, ensuring that ecological considerations are at the forefront of manufacturing processes. This commitment to sustainability reflects a growing recognition of the importance of eco-conscious practices in driving long-term success within global markets.