Understanding the Mechanics Behind Dump Truck Hydraulic Hoists: A Comprehensive Guide

In the world of construction and heavy-duty transportation, the efficiency and functionality of equipment can significantly impact productivity. One such essential piece of machinery is the Dump Truck Hydraulic Hoist, a vital component that allows for the quick and effective unloading of materials. Understanding how this system operates is crucial for operators and maintenance personnel alike.

This comprehensive guide delves into the mechanics behind Dump Truck Hydraulic Hoists, providing a step-by-step overview of their design, operation, and maintenance. By exploring the hydraulic principles governing these systems, readers will gain valuable insights into maximizing performance and ensuring safety while utilizing dump trucks in various applications.

Whether you're a seasoned professional or a newcomer to the industry, mastering the fundamentals of Dump Truck Hydraulic Hoists will empower you to operate with greater confidence and efficiency.

Understanding the Fundamentals of Dump Truck Hydraulic Hoists: Key Mechanisms Explained

Understanding the fundamentals of dump truck hydraulic hoists is essential for anyone involved in the construction and transportation industries. These hydraulic systems leverage fluid mechanics to lift heavy loads efficiently. A typical hydraulic hoist consists of several key components: the hydraulic pump, cylinders, and control valves. According to industry data, a well-maintained hydraulic hoist can provide lifting capabilities of up to 20 tons, making them indispensable for heavy-duty tasks.

When operating hydraulic hoists, it's crucial to ensure that the hydraulic fluid is clean and at the correct level. Contaminated fluid can lead to system failure and increased maintenance costs. Additionally, regular inspection of hoses and fittings can prevent leaks and downtime.

Tips: Always check the lift capacity of your dump truck's hydraulic system before operation to avoid overloading, which can cause hydraulic failure. It’s also advisable to train operators on proper hoisting techniques to enhance safety and efficiency on-site. Implementing a routine maintenance schedule can further extend the lifespan of the hydraulic hoist and prevent unexpected breakdowns.

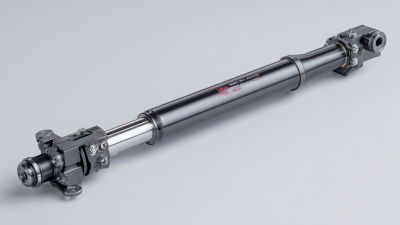

The Role of Hydraulic Cylinders in Enhancing Dump Truck Performance

Hydraulic cylinders play a pivotal role in enhancing the performance of dump trucks, especially when coupled with advanced hydraulic systems.

These cylinders convert hydraulic energy into mechanical force, allowing dump trucks to efficiently lift and tilt their cargo beds.

Recent advancements in hydraulic technology have led to significant improvements in both power and control. For instance, innovative systems are being developed to ensure precise operation even in challenging conditions.

This capability not only boosts productivity but also enhances operator comfort and safety, essential elements in modern construction and mining operations.

Hydraulic cylinders play a pivotal role in enhancing the performance of dump trucks, especially when coupled with advanced hydraulic systems.

These cylinders convert hydraulic energy into mechanical force, allowing dump trucks to efficiently lift and tilt their cargo beds.

Recent advancements in hydraulic technology have led to significant improvements in both power and control. For instance, innovative systems are being developed to ensure precise operation even in challenging conditions.

This capability not only boosts productivity but also enhances operator comfort and safety, essential elements in modern construction and mining operations.

As the demand for heavy machinery continues to rise, the implementation of high-pressure hydraulic solutions is becoming increasingly common. Reports indicate that the global heavy machinery components market is projected to grow significantly, driven by advancements in technology and the mining boom. Companies are focusing on creating more efficient hydraulic pumps and cylinders, which allow for flexible mounting options and improved performance. This ongoing evolution in hydraulic systems is critical in helping operators achieve peak performance levels while maximizing profitability, as seen in newly launched models across various brands in the industry.

Comparative Analysis: Hydraulic vs. Pneumatic Hoists in Heavy-Duty Applications

When it comes to heavy-duty applications, the choice between hydraulic and pneumatic hoists can significantly impact performance and efficiency. Hydraulic hoists operate using fluid pressure, which allows for greater lifting capacity and smoother operation. They are particularly advantageous in situations where heavy loads need to be lifted, as their design enables substantial force generation with minimal energy consumption. This makes hydraulic systems ideal for dump trucks, which often require the ability to lift and dump heavy materials quickly.

On the other hand, pneumatic hoists leverage compressed air to facilitate lifting actions. While they are generally lighter and can be faster in operation, their capacity is often limited compared to hydraulic counterparts. Pneumatic systems are suitable for specific applications that require rapid lifting and are commonly utilized in scenarios where electric or hydraulic power is impractical. However, they can be less efficient in terms of energy usage, especially when dealing with heavier loads. In summary, understanding the distinct features and capabilities of hydraulic and pneumatic hoists is crucial for selecting the most appropriate system for heavy-duty tasks.

Industry Standards for Dump Truck Hoist Durability and Load Capacity Measurements

When it comes to dump truck hydraulic hoists, understanding industry standards for durability and load capacity is essential for safe and efficient operations. These standards are established to ensure that hoists can withstand the extreme conditions typical in construction and heavy-duty environments. Factors such as material strength, design efficiency, and resistance to wear and tear play critical roles in determining the lifespan and reliability of a hydraulic hoist. By adhering to these regulations, manufacturers can guarantee that their products meet or exceed performance expectations, thereby enhancing safety for operators and minimizing downtime.

Load capacity measurements are another vital aspect that directly impacts operational reliability. Each hydraulic hoist is rated for a specific load limit, which is determined through rigorous testing procedures aligned with industry benchmarks. These ratings not only indicate the maximum weight that can be safely lifted but also factor in dynamic loads experienced during operation. Consequently, proper understanding and adherence to these measurements ensure that dump truck operators maximize their efficiency without risking overloading, which could lead to catastrophic failures, injury, or equipment damage. Regular inspections and maintenance in accordance with these standards are also crucial for sustaining optimal performance over time.

Understanding the Mechanics Behind Dump Truck Hydraulic Hoists: A Comprehensive Guide

| Dimension | Measurement Unit | Standard Value | Industry Reference |

|---|---|---|---|

| Hoist Capacity | Tons | 10 - 20 | SAE J1325 |

| Hydraulic Pressure | PSI | 2500 - 3000 | ISO 10772 |

| Cylinder Stroke Length | Inches | 36 - 48 | ANSI B30.20 |

| Weight of Hoist | Pounds | 600 - 1200 | AASHTO |

| Cycle Time | Seconds | 15 - 30 | SAE J1708 |

Real-World Efficiency: Examining Hydraulic Hoist Response Times and Material Handling Effectiveness

In the construction and mining industries, hydraulic hoists on dump trucks are pivotal for efficient material handling. Recent studies highlight that the response times of hydraulic hoists have a significant impact on productivity; industry reports indicate that modern hydraulic systems can achieve lift times as fast as 5 seconds, considerably reducing downtime during loading and unloading processes. This rapid response not only enhances the efficiency of operations but also allows for a quicker turnaround, which is critical in projects where time is money.

Moreover, the effectiveness of material handling through hydraulic hoists is underscored by operational data showing that trucks equipped with advanced hydraulic systems can increase load capacity by up to 15%. This efficiency translates to fewer trips and less fuel consumption, yielding cost savings for companies. The dynamic mechanics behind these hydraulic hoists ensure that they can handle heavy loads safely while maximizing performance. Industry experts advocate for the continuous evolution of hydraulic technology to further improve speed and efficiency, ensuring that dump trucks remain integral to effective logistics in heavy-duty applications.

Understanding the Mechanics Behind Dump Truck Hydraulic Hoists

This bar chart illustrates the average response times (in seconds) of hydraulic hoists for different load weights (in tons). The data highlights the effective material handling capabilities of hydraulic hoists based on load size.

Related Posts

-

7 Best Practices for Using Dump Truck Hydraulic Hoist Effectively

-

How to Choose the Right Hydraulic Cylinder for Excavator Efficiency and Performance

-

Ultimate Guide to Choosing the Best Hydraulic Oil Cylinder for Your Needs

-

How to Maximize Efficiency with Telescopic Cylinders in Heavy Machinery Operations

-

How to Choose the Right Telescopic Cylinders Underbody for Optimal Performance

-

7 Essential Tips for Choosing the Right Telescopic Cylinder