Understanding Dump Truck Hydraulic Hoist Mechanisms Explained

The "Dump Truck Hydraulic Hoist" plays a pivotal role in the construction and transportation industry. John Smith, a leading expert in heavy machinery, once stated, "The efficiency of a dump truck hinges on its hydraulic lift system." This mechanism allows heavy loads to be raised swiftly and safely, making it essential for any site.

Understanding how the "Dump Truck Hydraulic Hoist" operates is crucial. It involves a complex interplay of hydraulic fluid, pistons, and valves. This system enables the dump bed to elevate and tilt, ensuring materials are released effectively. Yet, many operators overlook the importance of regular maintenance. Neglecting small issues can lead to significant downtime.

The hydraulic hoist is not just a convenience; it’s a necessity. Inadequate knowledge about its workings can result in accidents and equipment failure. Learning about these mechanisms can empower operators, making their jobs safer and more efficient. The "Dump Truck Hydraulic Hoist" is a marvel of engineering, but like any system, it requires attention and care.

Overview of Dump Truck Hydraulic Hoist Mechanisms

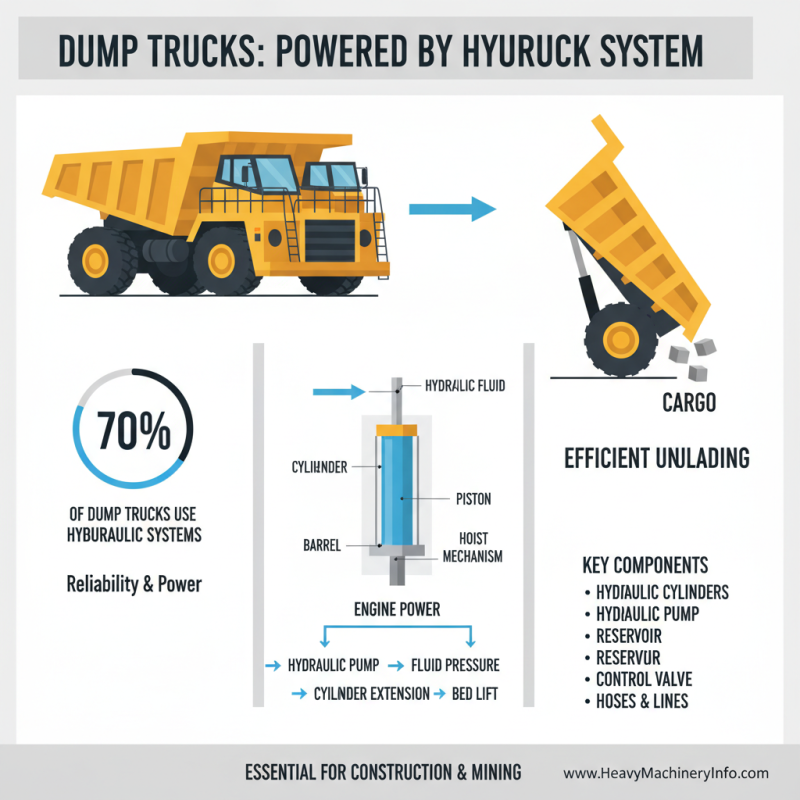

Dump trucks are essential in construction and mining. They rely on hydraulic hoist mechanisms for effective unloading. These systems typically utilize hydraulic cylinders, which lift the dump bed, enabling the cargo to be released efficiently. In the latest industry report, about 70% of dump trucks use hydraulic systems for their reliability and power.

The hydraulic hoist works by converting fluid pressure into mechanical force. This precision allows for unloading heavy loads, such as gravel or soil. A standard hydraulic system can lift loads ranging from 12 to 24 tons, depending on design. However, the mechanism's effectiveness can vary due to factors like maintenance and operating conditions. Hydraulic fluid levels must be monitored to prevent performance drops.

Moreover, while hydraulic hoists are powerful, they require regular servicing. Neglect can lead to leaks or pressure loss. Industry data indicates that about 15% of hydraulic failures are due to lack of maintenance. Operators should keep an eye on the condition of hoses and cylinders. Regular checks can prevent costly downtime and safety hazards.

Components of Hydraulic Systems in Dump Trucks

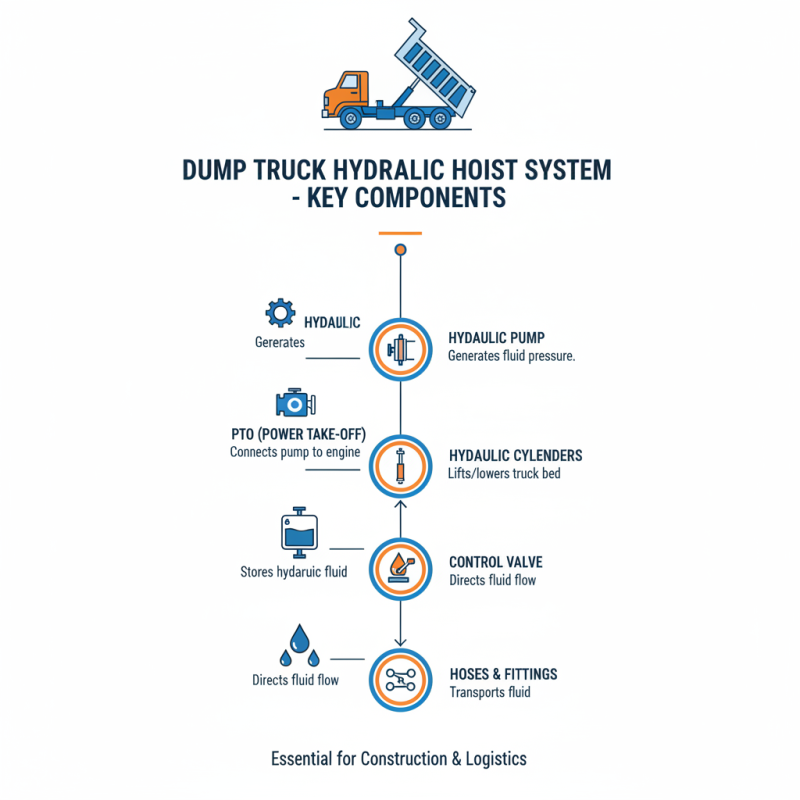

Dump trucks are essential in construction and logistics. Their hydraulic hoist systems play a critical role in their operation. Understanding these systems begins with recognizing key components.

The hydraulic pump generates pressure when activated. This pressure moves hydraulic fluid through the system. It then travels to the hydraulic cylinders, which lift the truck bed. Notably, the lifting mechanism needs to withstand heavy loads. Reports indicate that well-maintained hydraulic systems can lift over 14 tons effectively.

Tips: Regular fluid checks are vital. Contaminated hydraulic fluid can result in system failures. Inspect hoses and connections for leaks. Wear and tear can cause inefficiencies.

The control valve directs the flow of fluid. Operators can raise or lower the bed with precision. However, if the valve fails, it affects operation. Understanding these components will improve maintenance strategies. Knowing where potential issues lie is crucial. Regular training for operators can enhance efficiency in using these systems.

Working Principles of Hydraulic Lifting in Dump Trucks

Hydraulic lifting mechanisms in dump trucks function through fluid power. When the operator activates the system, hydraulic fluid moves through the lines. This fluid transfers force to a cylinder, which then pushes the hoist upward. The simplicity of this system makes it effective for lifting heavy loads with ease.

Each cylinder relies on a piston to generate the lifting force. As the hydraulic fluid enters the cylinder, it presses against the piston. This design allows for smooth and controlled lifting. The mechanism, however, is not infallible. Malfunctions can occur if there's a leak in the hydraulic system. Such leaks can lead to reduced effectiveness and safety concerns.

It’s essential to monitor the hydraulic fluid levels regularly. A lack of fluid can compromise the hoist's function. Operators should be trained to spot signs of wear and tear. Understanding these basic principles is vital for optimal performance. Regular maintenance is key to avoiding potential issues. Attention to detail can prevent larger problems down the line.

Common Issues and Maintenance Tips for Hydraulic Hoists

Hydraulic hoists in dump trucks play a crucial role in lifting and lowering loads. However, these systems often face common issues. Leaks are one of the most frequent problems. A small leak can lead to a significant loss of hydraulic fluid. It’s essential to regularly check hoses and fittings for signs of wear. If you notice fluid pooling under the truck, inspect it promptly.

Another common issue is the lack of maintenance. Neglect can cause parts to corrode or wear out. The hydraulic fluid itself needs changing after specific intervals. Old fluid can lead to system failure. Regularly flushing the system helps maintain optimal performance. Check the hydraulic filter during routine inspections. This is a quick way to ensure longevity.

Lastly, operators often overlook the importance of proper training. Ignorance about the system's limits can result in mishaps. Misuse can damage the hoist, leading to costly repairs. Training programs can help operators understand their equipment better. A little investment in knowledge can save time and money in the long run. Always aim for safety and efficiency on the job site.

Applications and Benefits of Hydraulic Hoisting in Dump Trucks

Hydraulic hoisting mechanisms in dump trucks are vital for efficiency. They allow quick unloading of materials like sand, gravel, and debris. This technology has transformed construction and mining industries. The benefits are clear: reduced manual labor, faster job completion, and improved safety. Operators can control loads with precision.

Tips: Regular maintenance is essential. Check hydraulic fluid levels frequently. Small leaks can lead to larger problems. Inspect hoses and connections regularly to ensure they are secure and functional.

Another advantage is versatility. Dump trucks equipped with hydraulic hoists handle various materials. They work efficiently on uneven terrain too. However, operators must be vigilant. Overloading the truck can lead to mechanical failure. Understanding the limits is crucial for safe operations.

Tips: Always follow load limits when using hydraulic hoists. Education on proper usage can prevent costly mistakes. Empowering operators enhances overall safety and productivity on the job site.

Related Posts

-

The Ultimate Guide to Dump Truck Hydraulic Hoist Innovations in 2025

-

7 Best Practices for Using Dump Truck Hydraulic Hoist Effectively

-

How to Choose the Right Dump Truck Hydraulic Hoist for Your Needs?

-

Why Choosing a Dump Truck Hydraulic Hoist Is Essential for Efficient Construction Operations

-

Top 10 Benefits of Using Dump Truck Hydraulic Hoists for Your Projects

-

Unmatched Quality in Telescopic Cylinders Shaping Global Manufacturing Excellence from China