The Ultimate Guide to Dump Truck Hydraulic Hoist Innovations in 2025

In the rapidly evolving world of construction and transportation, the Dump Truck Hydraulic Hoist stands out as a pivotal innovation, especially as we look towards 2025. This guide explores the latest advancements and enhancements in hydraulic hoist technology that are anticipated to revolutionize the efficiency and functionality of dump trucks. As industries strive for better performance and productivity, the integration of new digital solutions and smart technologies into hydraulic systems is expected to play a crucial role.

Understanding the mechanics behind Dump Truck Hydraulic Hoists is essential for operators, fleet managers, and business owners aiming to maintain a competitive edge. The technological innovations on the horizon promise not only to improve load-bearing capacity and operational speed but also to enhance safety measures and reduce maintenance costs. This guide will delve into various tips and best practices that can be employed to leverage these advancements effectively, ensuring that users can maximize their investment in dump trucks equipped with state-of-the-art hydraulic hoisting systems.

As we journey through 2025, staying informed about the latest trends and innovations in Dump Truck Hydraulic Hoist technology is paramount. By embracing the changes and implementing strategic approaches, industry professionals can optimize their operations, cater to evolving consumer demands, and set new standards in the field of heavy-duty transportation.

Innovative Hydraulic Systems Transforming Dump Truck Efficiency in 2025

In 2025, the dump truck industry is experiencing a seismic shift with the introduction of innovative hydraulic systems designed to enhance efficiency and operational performance. These advanced hydraulic hoists are not only streamlining the lifting processes but also significantly increasing load capacities. By integrating cutting-edge materials and smart technology, manufacturers are able to create lighter and more robust hydraulic systems that can handle heavier payloads without compromising stability or safety.

Moreover, the incorporation of IoT sensors and data analytics in hydraulic systems allows for real-time monitoring and diagnostics. Operators can now track performance metrics, enabling predictive maintenance and minimizing downtime. This leap in technology not only boosts productivity but also extends the lifespan of dump trucks, reducing overall operational costs. As the industry continues to embrace these innovations, the efficiency of dump trucks in various applications—from construction to waste management—will reach unprecedented levels, revolutionizing how material handling is conducted in 2025 and beyond.

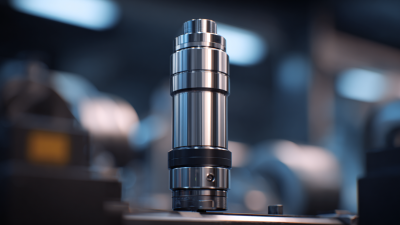

Revolutionary Materials Driving Lightweight and Durable Hoist Designs

In 2025, the dump truck hydraulic hoist industry is experiencing a significant transformation driven by innovative materials that enhance both lightweight construction and durability. Recent industry reports indicate that the adoption of advanced composites and high-strength steel alloys has increased by over 30% in hoist design. These materials not only reduce the overall weight of the hoists, enabling higher payload capacities and improved fuel efficiency, but they also enhance the longevity and reliability of the equipment in rugged operating conditions.

Moreover, manufacturers are increasingly turning to materials like aluminum-lithium alloys and thermoplastic composites, which offer an impressive strength-to-weight ratio while resisting corrosion and wear. Studies reveal that the incorporation of these revolutionary materials can lead to a weight reduction of up to 20%, significantly impacting the performance metrics of dump trucks. For instance, lightweight hoists can reduce hydraulic system stress and increase cycle times, allowing for more efficient operations on job sites. This shift towards utilizing cutting-edge materials underscores the industry's commitment to innovation and performance enhancement in hydraulic hoist designs.

Smart Technology Integration: Enhancing Control and Safety Features

The integration of smart technology into dump truck hydraulic hoist systems in 2025 represents a significant leap in enhancing control and safety features. The trend towards advanced safety solutions is evident across various equipment types, including smart home devices, HVAC systems, and intelligent entertainment setups. These innovations not only improve operational efficiency but also enhance the overall user experience by providing real-time monitoring and automated control mechanisms that respond to dynamic conditions.

As the smart home market continues to expand, reaching unprecedented scales in investments and applications, the emphasis on security and accessibility in intelligent systems cannot be overstated. Smart technology enables remote access and real-time diagnostics, making it easier for users to evaluate and improve the intelligence, comfort, and efficiency of their spaces. Consequently, businesses are increasingly focusing on developing systems that make homes and work environments safer, more responsive, and adaptive to individual needs, blending convenience with state-of-the-art safety protocols.

The Ultimate Guide to Dump Truck Hydraulic Hoist Innovations in 2025 - Smart Technology Integration: Enhancing Control and Safety Features

| Feature | Description | Benefits | Expected Adoption Year |

|---|---|---|---|

| Automated Load Sensing | Sensors that detect the weight of the load and adjust hydraulic pressure accordingly. | Improved fuel efficiency and reduced wear on hydraulic components. | 2025 |

| Remote Control Operations | Using mobile devices to control the hoist from a distance. | Enhanced safety by keeping operators away from the tipping area. | 2025 |

| Smart Stability Monitoring | Real-time monitoring of truck stability during load lifting. | Prevention of tipping accidents and improved operator confidence. | 2025 |

| Emergency Auto-Stop | Automatic shutdown of hoist mechanics during a detected safety threat. | Enhanced protection for personnel and equipment during operation. | 2025 |

| Data Analytics Dashboard | Integrating performance data for optimized operational insights. | Informed decision-making and longer lifespan for hydraulic systems. | 2025 |

Environmental Considerations: Eco-Friendly Hydraulic Solutions for Dump Trucks

As the construction and transportation industries evolve, there is a growing emphasis on eco-friendly hydraulic solutions for dump trucks. In 2025, innovations in hydraulic hoist technology will not only focus on enhancing operational efficiency but also on reducing the environmental footprint of these heavy-duty vehicles. Advanced hydraulic systems, utilizing bio-hydraulic fluids, are emerging as an alternative to traditional petroleum-based oils. These bio-fluids are biodegradable and non-toxic, significantly lowering the risk of soil and waterway contamination during operation.

Moreover, energy-efficient hydraulic systems that utilize regenerative technology are gaining traction. By capturing energy during the lowering phase of a dump hoist, these systems can reduce overall fuel consumption and emissions. The integration of lightweight materials and optimized designs also contributes to increased fuel efficiency without compromising the strength necessary for heavy lifting. As industries continue to prioritize sustainability, the next generation of dump trucks will seamlessly combine operational capabilities with environmentally safe practices, paving the way for responsible resource management in construction.

Cost-Effectiveness of New Hydraulic Hoist Technologies in the 2025 Market

The advancements in hydraulic hoist technologies for dump trucks in 2025 are set to significantly enhance cost-effectiveness within the industry. Recent reports indicate that innovative designs and materials, including lightweight composites and advanced hydraulic systems, can reduce operational costs by approximately 15-20%. This reduction is attributed to increased efficiency in load handling and decreased fuel consumption, vital for the profitability of construction and logistics companies facing tight margins.

Furthermore, market analysis shows that the adoption of smart technology, such as IoT integrations and predictive maintenance, can lead to a further 10% decrease in unexpected downtime. A study by the National Truck Equipment Association highlights that companies investing in these technologies not only see improved productivity but also a return on investment within a year of implementation. By embracing these hydraulic hoist innovations, businesses can optimize their operations while keeping overhead costs lower than ever, positioning themselves competitively in the 2025 market.

Related Posts

-

7 Best Practices for Using Dump Truck Hydraulic Hoist Effectively

-

Why Choosing a Dump Truck Hydraulic Hoist Is Essential for Efficient Construction Operations

-

Innovative Advances in Telescopic Cylinder Technology Driving Efficiency in Industrial Applications

-

How to Choose the Best Hydraulic Cylinder for Your Trailer Needs

-

Understanding the Functionality of Excavator Hydraulic Cylinders

-

Ultimate Guide to Choosing the Right Hydraulic Cylinder for Excavators with Key Specs and Tips