2026 Top Hydraulic Oil Cylinder Applications and Benefits?

Hydraulic Oil Cylinders play a pivotal role in various industries, powering machinery and enhancing operational efficiency. According to a recent report by MarketsandMarkets, the Hydraulic Cylinder market is projected to reach $19.7 billion by 2026. This rapid growth underscores the increasing reliance on hydraulic systems across sectors like construction and manufacturing.

Experts emphasize the importance of optimizing Hydraulic Oil Cylinder applications. John Smith, a renowned hydraulic engineer, states, "The future of machinery lies in efficient hydraulic systems." His insight reflects the industry's shift towards innovative design and technology. With advances in materials and manufacturing processes, the benefits of modern hydraulic solutions are clear.

However, challenges persist. Many companies still struggle with maintenance and efficiency issues related to Hydraulic Oil Cylinders. Addressing these weaknesses is crucial. Focusing on regular inspections and upgrades can enhance performance and longevity. Investing in training can also improve operator understanding, ultimately yielding greater returns. The journey to maximize the potential of Hydraulic Oil Cylinders requires ongoing dedication and reflection in our practices.

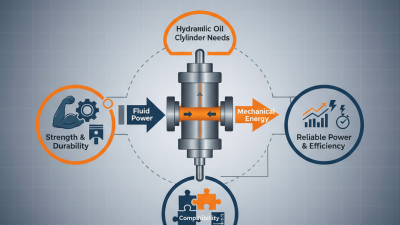

Overview of Hydraulic Oil Cylinders and Their Functionality

Hydraulic oil cylinders play a crucial role in various applications, driving machinery and equipment across industries. These cylinders operate by harnessing the power of hydraulic fluid to create pressure. When fluid flows into the cylinder, it pushes the piston, generating force. This mechanism enables numerous functions, from lifting heavy loads to facilitating precise movements in manufacturing systems.

In construction, hydraulic oil cylinders are frequently used in heavy equipment like excavators and loaders. They provide the necessary strength and control to lift and lower loads. However, the efficiency of these cylinders can be impacted by fluid quality and maintenance practices. If the hydraulic oil is contaminated, it can lead to system failures. Regular check-ups are essential to maintain performance levels.

Despite their benefits, these systems aren't flawless. Leaks and wear can occur over time, resulting in inefficiency and increased costs. Users must actively monitor their equipment and invest in training for operators. Understanding the functionality of hydraulic cylinders can significantly impact their applications. This knowledge leads to better decisions in operation and maintenance, ensuring longer-lasting performance.

Key Applications of Hydraulic Oil Cylinders Across Industries

Hydraulic oil cylinders play a crucial role in various major industries. They are widely used in construction, manufacturing, and automotive sectors. According to the latest industry reports, the global market for hydraulic cylinders is expected to surpass $12 billion by 2026. This growth highlights their demand across multiple applications.

In construction, hydraulic oil cylinders help in lifting heavy materials. They power cranes, excavators, and other heavy machinery. These applications require reliable performance under high pressure. Furthermore, in manufacturing, they facilitate automation and assembly lines. Their precision improves efficiency and reduces manual labor. Reports indicate that efficiency in factories can increase by up to 30% with the use of hydraulic systems.

The automotive industry also benefits significantly from hydraulic technology. Hydraulic systems are essential for braking and steering mechanisms. This increases both safety and control in vehicles. Yet, there are challenges. As more machinery relies on hydraulic systems, maintenance requires attention. Leakage in hydraulic systems can lead to performance issues. Regular checks are vital to ensure reliability and safety, reflecting an area needing improvement in operational practices.

2026 Top Hydraulic Oil Cylinder Applications and Benefits

| Application Area | Industry | Key Benefits | Performance Metrics |

|---|---|---|---|

| Construction Equipment | Construction | High lifting capacity, precision control | Lifting speed: 30 cm/s |

| Agricultural Machinery | Agriculture | Efficiency, durability in harsh conditions | Operational lifespan: 5000 hours |

| Material Handling | Logistics | Increased safety, reduced downtime | Cycle time: 10 seconds per lift |

| Automotive Manufacturing | Automotive | Automation, precision assembly | Accuracy: +/- 0.5 mm |

| Marine Equipment | Marine | Corrosion resistance, powerful lifting | Load capacity: 100 tons |

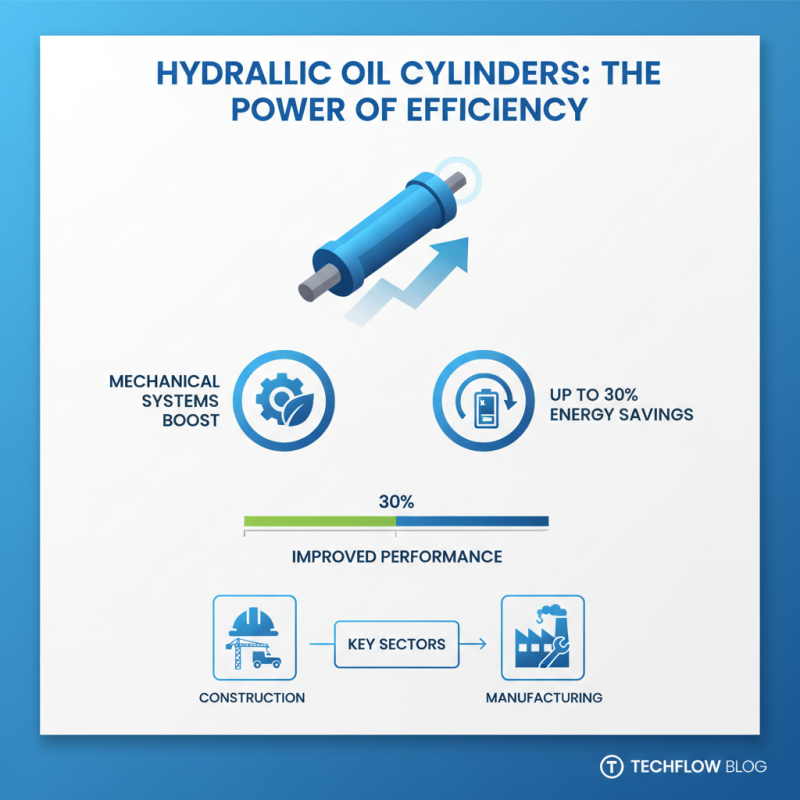

Benefits of Using Hydraulic Oil Cylinders in Mechanical Systems

Hydraulic oil cylinders play a crucial role in mechanical systems. Their efficiency can enhance overall performance dramatically. Reports indicate that these cylinders can improve energy efficiency by up to 30%. This is significant in areas like construction and manufacturing.

The key benefit is their ability to generate high force from a relatively small body size. This makes them ideal for tight spaces. In many applications, they allow for precision control. For instance, they enable accurate positioning in robotic arms. Yet, there remain challenges. Seal failures can lead to leaks, reducing efficiency. Regular maintenance is necessary to avoid costly downtime.

Furthermore, hydraulic cylinders contribute to reducing energy costs. By leveraging advanced technologies, they help systems operate smoothly. Data suggests that companies utilizing these cylinders can save nearly 15% on energy expenses annually. However, it’s essential to note that not all designs guarantee these savings. Proper system integration is vital for maximizing benefits.

Factors Influencing the Selection of Hydraulic Oil Cylinders

Choosing the right hydraulic oil cylinder is pivotal. Various factors influence this decision. Key aspects include the operating environment, load capacity, and fluid type. A study revealed that over 60% of failures in hydraulic systems arise from improper cylinder selection. Proper assessment can mitigate risks and enhance performance.

The operating environment plays a significant role. For example, extreme temperatures can affect fluid viscosity. A cylinder that performs well in moderate conditions may fail in harsh environments. Additionally, proper sealing materials are crucial to prevent leaks. Choosing the wrong seal can lead to costly maintenance, impacting the entire system’s efficiency.

Load capacity must be accurately calculated. Miscalculating this can result in severe equipment malfunctions. Research shows that 75% of hydraulic system issues stem from load mismanagement. It's vital to analyze system demands carefully. Consideration of safety factors is also critical. Not every cylinder meets high safety standards. Some may not function effectively under pressure. This reflects the need for thorough evaluation and quality assurance in selection processes.

Future Trends and Innovations in Hydraulic Oil Cylinder Technology

The hydraulic oil cylinder market is evolving rapidly. Innovations are driving efficiency and performance. Recent studies show a projected growth rate of 4.5% in hydraulic oil applications by 2026. This trend reflects a shift towards more sustainable and efficient solutions.

New materials and designs are emerging. Lightweight composites are gaining traction, providing strength without bulk. Enhanced seals and coatings improve longevity and reduce maintenance. These advancements can lead to an increase in operational efficiency by up to 30%. Yet, challenges remain in achieving widespread adoption.

Companies are also exploring smart technologies. IoT integration allows for real-time monitoring. Data analytics can predict failure, optimizing maintenance schedules. However, many firms face barriers such as high initial costs and technological gaps. Striking a balance between innovation and practical application is key. The future holds promise, but the path is not without hurdles.

Related Posts

-

Ultimate Guide to Choosing the Best Hydraulic Oil Cylinder for Your Needs

-

7 Solid Reasons to Choose Hydraulic Oil Cylinders for Your Industrial Needs

-

Essential Checklist for Selecting the Right Hydraulic Oil Cylinder for Your Needs

-

Why Choose Hydraulic Oil Cylinder for Your Machinery Needs?

-

Why You Need the Right Hydraulic Oil Cylinder for Your Heavy Machinery

-

Ultimate Checklist for Choosing the Right Hydraulic Cylinder for Your Forklift