Ultimate Tips for Choosing Telescopic Cylinders Underbody for Your Vehicle?

When selecting Telescopic Cylinders Underbody for your vehicle, it's crucial to consider various factors. These components play a vital role in your vehicle's performance. They are essential for load handling and stability. Understanding their importance can help you make informed choices.

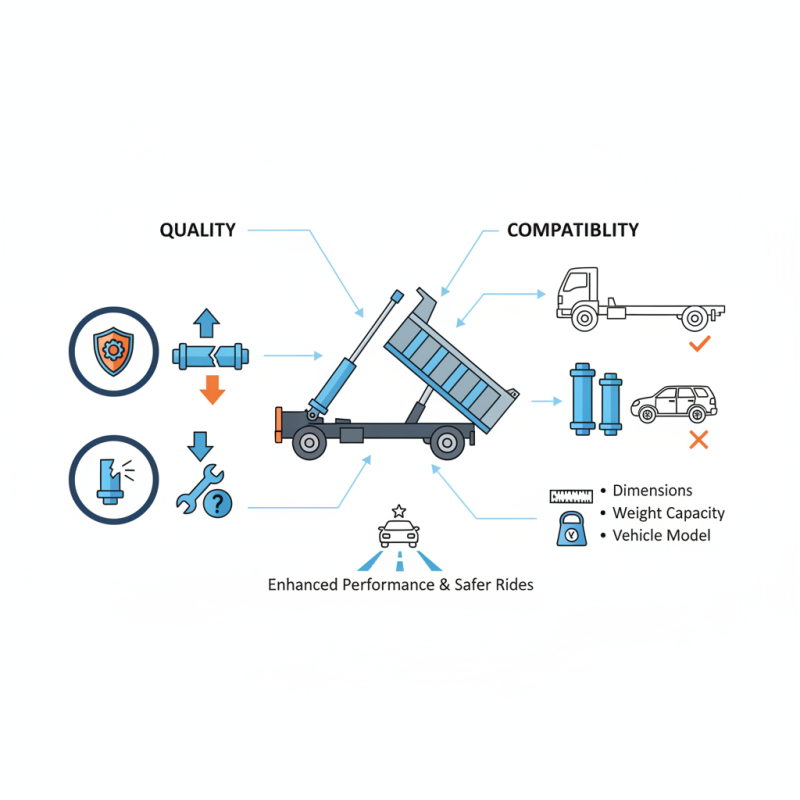

Quality matters. A high-quality telescopic cylinder can enhance your vehicle's durability. It may withstand harsher conditions and provide reliable operation. Conversely, low-quality options may lead to unexpected failures. This can seriously affect your vehicle’s functions.

In addition, compatibility with your vehicle model is key. Not all cylinders fit every make or model. Checking specifications can save you frustration. Pay attention to dimensions and weight capacities. Taking time to research ensures you select the right option. Remember, the goal is to enhance your vehicle's performance for safer rides.

Understanding Telescopic Cylinder Types for Vehicle Underbodies

When selecting telescopic cylinders for your vehicle's underbody, understanding the types is crucial. Telescopic cylinders come in various designs. They can be single-acting or double-acting. Single-acting cylinders only use pressure in one direction. Double-acting cylinders provide force in both directions. Knowing which type suits your needs can prevent costly mistakes.

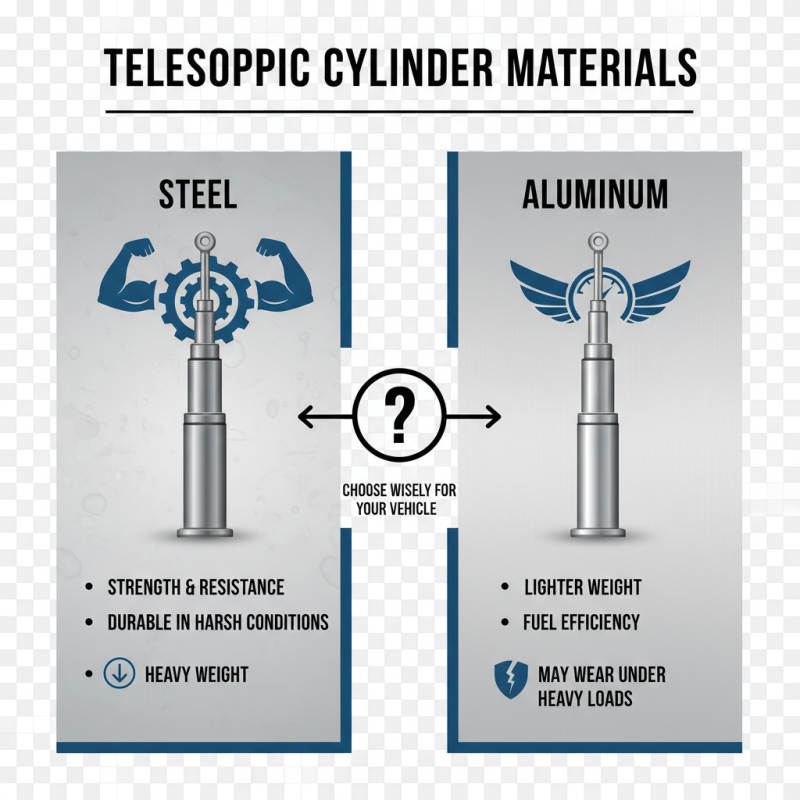

Consider the material of the cylinder. Steel and aluminum are popular choices. Steel is strong but heavier, while aluminum is lighter and resistant to rust. Each has its advantages and drawbacks. Weight could affect vehicle performance. Think about how this might influence your decision. The cylinder's stroke length is also essential. Ensure it meets your vehicle's requirements. A mismatch can lead to underperformance or failure.

Installation can be tricky. Ensure proper alignment and secure fittings. A small error here can lead to leaks. It’s vital to reflect on the mounting points directly. They should match the vehicle’s structure perfectly. Otherwise, durability is compromised. Spending time on these details now can save you future headaches.

Evaluating Material Durability and Load Capacity in Telescopic Cylinders

When choosing telescopic cylinders for your vehicle, material durability is a critical factor. These cylinders often endure harsh conditions, so selecting robust materials is vital. Steel is a popular choice due to its strength and resistance. However, its weight can be a drawback. Aluminum is lighter but may wear faster under heavy loads. Understanding these material properties helps in making an informed choice.

Load capacity is equally important. Each cylinder has a specified load limit. Exceeding this could lead to failure. It’s essential to calculate the expected loads accurately. Consider dynamic loads as well. They can be higher than static loads at times. Sometimes, this can be overlooked, leading to problems. Regular testing and maintenance might be required to ensure performance and safety.

Reflecting on these aspects can help avoid future issues. Choosing the right material and ensuring adequate load capacity are not just technicalities. They directly impact your vehicle's efficiency and safety. Take time to evaluate each option carefully. Every choice makes a difference in the long run.

Key Specifications to Consider: Stroke Length and Pressure Ratings

When selecting telescopic cylinders for your vehicle's underbody, stroke length and pressure ratings are critical specifications. Stroke length determines how much the cylinder can extend and retract, impacting the vehicle's suspension and load handling capabilities. According to industry reports, an ideal stroke length ranges from 6 to 12 inches for standard applications. A mismatch can lead to inefficiencies or even mechanical failure.

Pressure ratings also play a vital role. These ratings indicate the maximum pressure the cylinder can withstand during operation. Most hydraulic cylinders operate in the range of 1,500 to 3,000 psi. Higher pressure ratings often mean better performance, but they can also increase the risk of failure if not paired with appropriate components. Operators should consider the demands of their specific application when choosing a pressure rating.

The reality is that choosing the right specifications requires careful consideration. Often, users focus only on performance parameters but overlook the importance of proper installation. An incorrect setup can negate the benefits of selected stroke lengths and pressure ratings. This oversight may lead to inefficiencies and safety risks that could have been easily avoided. Always reflect on the specific needs of your vehicle and application before making a decision.

Installation and Maintenance Best Practices for Telescopic Cylinders

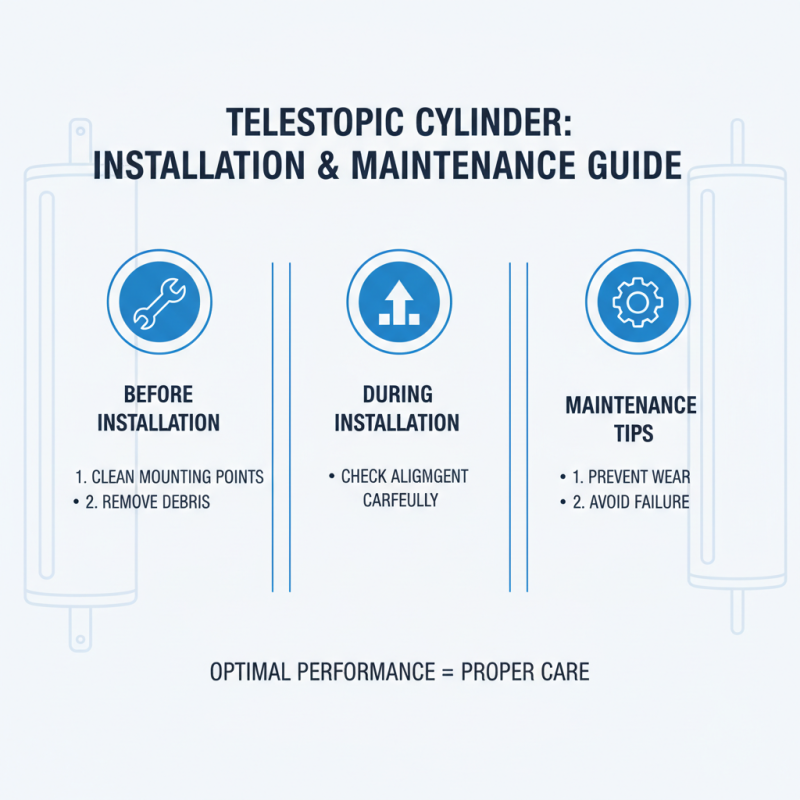

When it comes to telescopic cylinders, proper installation and maintenance are crucial for optimal performance. Before installation, ensure that the mounting points on your vehicle are clean and free of debris. This simple step can make a significant difference. Check the alignment of the cylinders carefully during installation. Misalignment can lead to premature wear or failure.

Regular maintenance cannot be overlooked. Inspect the cylinders for any signs of leaks. A small leak can quickly escalate into a major issue. Additionally, check the hydraulic fluid levels; maintaining the right level is essential for smooth operation. Clean the rods frequently to prevent dirt and debris from causing damage. Small particles can lead to significant wear over time.

Remember that telescopic cylinders require occasional recalibration. If your vehicle's performance feels off, don’t ignore it. Reflect on the last time you serviced the cylinders. Even minor adjustments can lead to improvements. Keeping a maintenance log can help you track issues, making it easier to see patterns. Regular attention to these details ensures your vehicle operates safely and efficiently.

Comparing Cost-Effectiveness of Various Telescopic Cylinder Brands

When assessing cost-effectiveness in telescopic cylinders, several factors come into play. Quality and durability are paramount, impacting overall lifetime costs. A report from the Hydraulic & Pneumatic Industries Association notes that up to 20% of total operational costs can stem from inefficient cylinder performance. In real-world scenarios, this translates to enhanced downtime and increased maintenance.

Moreover, while some brands present lower initial prices, it’s essential to consider longevity. A study indicated that high-quality cylinders can last up to 30% longer than their cheaper counterparts. This means saving money in the long run on replacements and repairs. Focusing on performance ratings helps ensure you’re making a sound investment.

However, it’s not always straightforward. Price fluctuations among brands can confuse buyers. A detailed analysis often draws attention to overlooked costs in servicing. Choosing a cylinder solely based on initial cost can lead to regret later on. Finding balance requires thorough research and understanding of each product's total cost of ownership.

Ultimate Tips for Choosing Telescopic Cylinders Underbody for Your Vehicle

| Feature | Brand A | Brand B | Brand C |

|---|---|---|---|

| Maximum Load Capacity (tons) | 5 | 4.5 | 6 |

| Stroke Length (mm) | 300 | 250 | 350 |

| Material | Aluminum | Steel | Composite |

| Warranty (years) | 2 | 3 | 5 |

| Price ($) | 150 | 130 | 180 |

| User Rating (out of 5) | 4.2 | 3.9 | 4.7 |

Related Posts

-

The Ultimate Guide to Sourcing Telescopic Cylinders Underbody for Global Buyers

-

Ultimate Guide to Mastering Telescopic Cylinders Underbody for Enhanced Performance

-

Exploring Alternative Solutions for Telescopic Cylinders Underbody Applications

-

The Ultimate Guide to Understanding Telescopic Cylinders Underbody Applications and Benefits

-

2025 Top Insights on Telescopic Cylinders Underbody Technology and Applications

-

Essential Tips for Identifying Reliable Manufacturers of Best Telescopic Cylinders Underbody