Top Tips for Choosing the Right Excavator Hydraulic Cylinder for Your Needs

Choosing the right excavator hydraulic cylinder is crucial for efficient machinery operation. According to industry reports, improper selection can lead to significant downtime and costly repairs. In 2022, equipment failure due to hydraulic issues accounted for 20% of total maintenance costs in construction fleets.

Excavator hydraulic cylinders are the backbone of heavy machinery. They provide the necessary force to lift and move heavy loads. Selecting the wrong cylinder can compromise safety and productivity. The market is flooded with options, making the decision daunting for many operators. Size, pressure rating, and material are among the key factors to consider.

It’s not just about specifications. Understanding your specific application is essential. Many operators invested in hydraulic cylinders that did not meet their unique needs, leading to inefficiencies. Insightful analysis of your work environment can save time and money in the long run. A well-chosen excavator hydraulic cylinder enhances performance and reduces the risk of equipment failure.

Understanding Excavator Hydraulic Cylinder Specifications and Types

Choosing the right excavator hydraulic cylinder requires a clear understanding of specifications and types. Hydraulic cylinders mainly come in two types: single-acting and double-acting. Single-acting cylinders can extend using hydraulic pressure but rely on gravity or external force to retract. In contrast, double-acting cylinders operate in both directions. A study by the International Journal of Engineering Research suggests that double-acting cylinders account for about 70% of market demand due to their versatility.

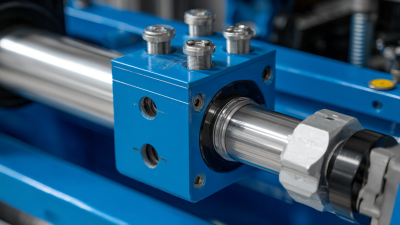

When evaluating specifications, several factors matter. Cylinder diameter directly influences lifting capacity. A report by Machinery Insights indicated that a cylinder with a diameter of 100 mm can lift approximately 5 tons at peak hydraulic pressure. Stroke length also affects performance; longer strokes enable more extensive work range but may complicate installation. Additionally, seal materials impact the cylinder's lifespan. For example, neoprene seals are common, but they may not perform well in extreme temperatures. This discrepancy often leads to maintenance challenges.

It's vital to consider the application. Construction tasks may necessitate a higher bore size, while demolition work could demand robust seals for longevity. Not all projects can anticipate hydraulic needs accurately. Errors in calculating pressures or loads can lead to inefficiencies or mechanical failures. Thus, the choice of hydraulic cylinder should reflect a deep understanding of specific job requirements and potential limitations.

Evaluating Load Capacity and Performance Requirements for Excavators

Choosing the right hydraulic cylinder for an excavator involves careful consideration of load capacity. Each excavator model has specific weight limits. If the cylinder can’t handle the load, it can lead to failures. Evaluating the weight of materials to be moved is crucial. Calculate the maximum weight your excavator needs to lift.

Performance requirements also play a big role. The efficiency of the hydraulic system affects the overall performance. A cylinder that operates smoothly can make a big difference. Take note of the speed at which you need to operate. Some tasks require quick movement, while others benefit from precision. Evaluate how these factors align with your project goals.

Measuring the stroke length is another essential detail. A cylinder that doesn’t match the required stroke can cause significant issues. However, be aware that longer strokes can decrease lifting power. It’s vital to balance these needs. Overlooking the small details can lead to big problems later. Keep performance and capacity aligned to truly meet your operational demands.

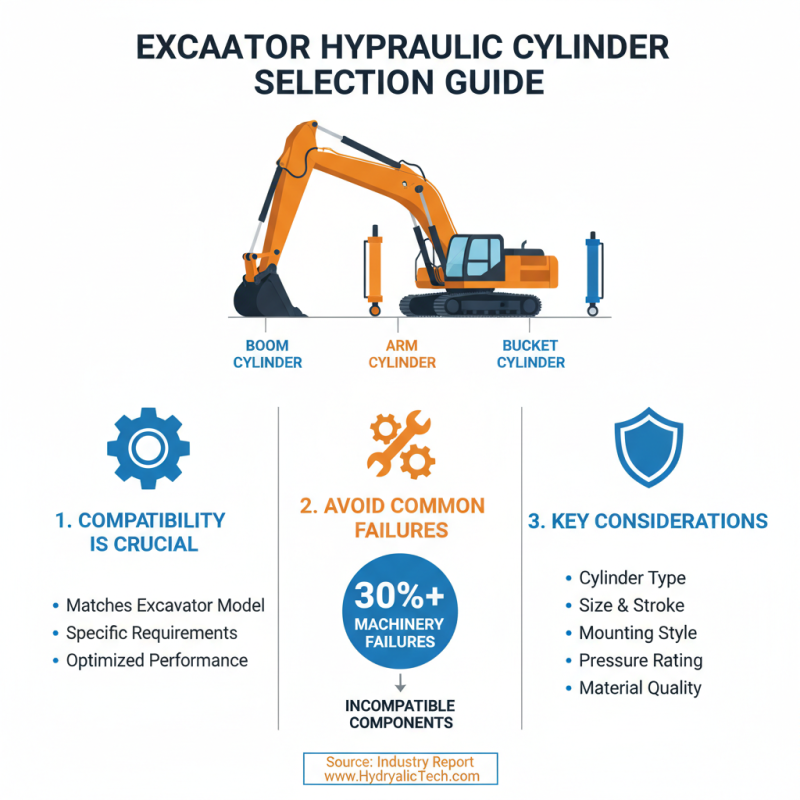

Assessing Compatibility with Excavator Models and Operating Environments

Choosing the right hydraulic cylinder for an excavator isn't straightforward. Compatibility with your specific excavator model matters greatly. Different models have unique requirements that can affect performance. In a recent industry report, it was highlighted that over 30% of machinery failures stem from incompatible components. This statistic emphasizes the importance of matching the cylinder to the excavator's specifications.

Operating environments also play a crucial role. Cylinders must withstand extreme conditions, such as high temperatures or corrosive materials. According to the National Institute for Occupational Safety and Health, excavators often work in rocky or uneven terrain. This can cause wear and tear on hydraulic components that aren't suited for such challenges. If the wrong cylinder is chosen, it might underperform or fail unexpectedly.

Furthermore, installation can reveal compatibility issues. A poorly fitted cylinder might show hydraulic leaks or inconsistent lifting power. Such problems can lead to downtime, affecting project timelines. Regular assessments of cylinder performance in real-world conditions can help identify these flaws early. These proactive measures ensure you select a cylinder that not only fits but also enhances the excavator's overall efficiency.

Investigating Maintenance and Durability Factors in Hydraulic Cylinders

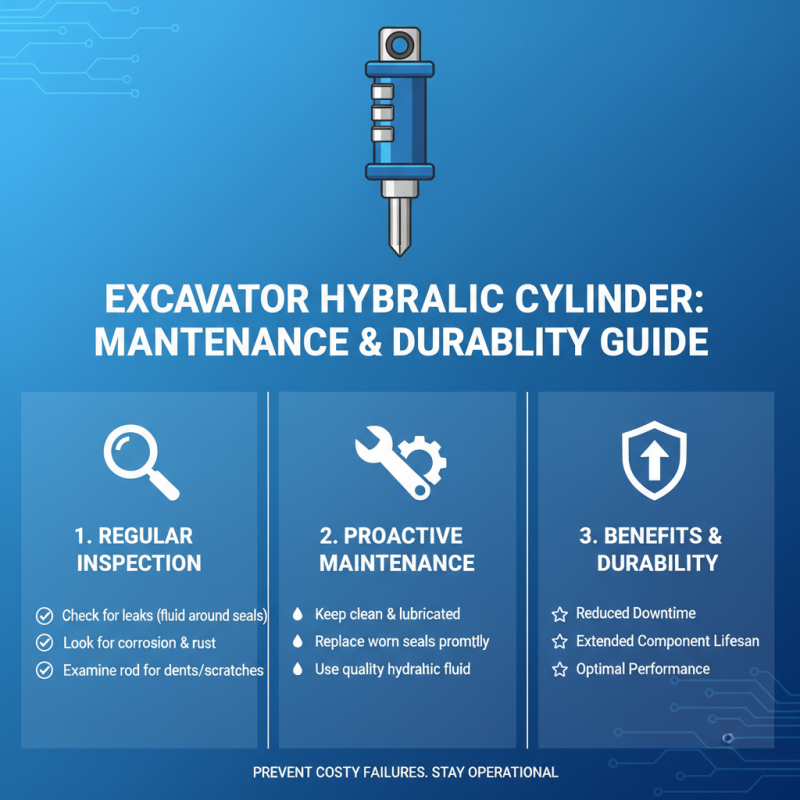

When selecting an excavator hydraulic cylinder, maintenance and durability are crucial factors. A poorly maintained cylinder can lead to significant downtime. Regular inspection is necessary. Look for signs of wear, such as leaks or corrosion. If any issues arise, address them immediately to prevent further damage.

The material of the hydraulic cylinder affects its lifespan. Tough materials resist wear better but can be expensive. Sometimes, people overlook this aspect to save costs. While cheaper options may seem appealing, they often result in more frequent repairs. This pattern can become frustrating and counterproductive.

Durability also depends on design. Some designs improve performance but complicate maintenance. It is vital to balance ease of maintenance with durability. Be wary of overly complex systems. They can be tempting but might lead to future headaches. A simple, robust design can often outlast a more intricate one.

Analyzing Cost Efficiency and Long-Term Investment for Hydraulic Solutions

When selecting an excavator hydraulic cylinder, cost efficiency is essential. A high-quality cylinder can significantly reduce maintenance costs over time. However, it is vital to evaluate initial expenses versus long-term savings. A cheaper option might seem appealing, but it could lead to frequent repairs. Investing wisely today ensures your machinery performs efficiently for years.

Consider the materials and construction of the hydraulic cylinder. Components made with durable materials often last longer. This durability means fewer replacements and reduced downtime. Weighing different options can be overwhelming. Not every cylinder meets the required specifications for every machine. Rushed decisions can lead to compatibility issues, causing further costs down the line.

Think about the working environment of your equipment. Harsh conditions may necessitate specialized cylinders. They might come with a higher price tag. However, this could be a smarter investment in the long run. Identifying the specific needs of your projects can help. A thorough analysis of usage patterns and potential challenges is key. Adjusting your choices based on real demands can save money and time.

Related Posts

-

Best Excavator Hydraulic Cylinder Maintenance Tips for Optimal Performance

-

Understanding the Role of Excavator Hydraulic Cylinders in Modern Construction Machinery

-

A Comprehensive Guide to Selecting the Best Hydraulic Cylinder for Your Trailer Needs

-

Understanding the Functionality of Excavator Hydraulic Cylinders

-

How to Choose the Right Hydraulic Cylinder for Your Forklift Needs Based on Load Capacity

-

Understanding Excavator Hydraulic Cylinders: Essential Maintenance Tips for Optimal Performance