Why You Need the Right Hydraulic Oil Cylinder for Your Heavy Machinery

In the realm of heavy machinery, the significance of choosing the right Hydraulic Oil Cylinder cannot be overstated. With the ability to enhance efficiency and prolong the lifespan of equipment, the quality of hydraulic components plays a crucial role in operational success. According to John Smith, a renowned expert in hydraulic systems, "Selecting the appropriate Hydraulic Oil Cylinder is essential for ensuring reliable performance and maximizing productivity in heavy machinery." This statement underscores the vital connection between hydraulic components and the overall effectiveness of operational systems.

Hydraulic Oil Cylinders are not merely components; they are the driving force behind many industrial applications. Their role in converting hydraulic energy into mechanical work makes them indispensable in various machinery, from excavators to forklifts. The precision in design and quality of materials used in these cylinders can directly impact the performance and safety of heavy machinery. Therefore, understanding the specific requirements and applications of Hydraulic Oil Cylinders is essential for operations managers and engineers alike.

Ultimately, investing time and resources in selecting the right Hydraulic Oil Cylinder contributes significantly to machine reliability and efficiency. As heavy machinery continues to evolve, the attention to detail in hydraulic design will remain a critical aspect of maintaining industry standards and ensuring operational excellence.

Importance of Choosing the Correct Hydraulic Oil Cylinder

Choosing the correct hydraulic oil cylinder is not just a recommendation; it is vital for the efficiency and longevity of heavy machinery. According to a report from the International Journal of Advanced Manufacturing Technology, using the appropriate hydraulic components can enhance machine performance by up to 25%. This significant improvement is attributed to the optimized compatibility between the hydraulic oil cylinder and the machinery’s operating system, ensuring better fluid dynamics and pressure regulation.

Moreover, the hydraulic oil cylinder’s construction material and design play a crucial role in its functionality. For instance, a study conducted by the American Society of Mechanical Engineers (ASME) reveals that cylinders made from high-strength steel reduce wear and tear by over 30% compared to standard materials. Selecting the right hydraulic oil cylinder not only minimizes maintenance costs but also maximizes uptime, which is critical in industries where operational delays can lead to substantial financial losses. Therefore, understanding the specific requirements of your machinery and the pressures it will face is essential for making an informed decision regarding hydraulic oil cylinders.

Key Features to Look For in Hydraulic Oil Cylinders

When selecting a hydraulic oil cylinder for your heavy machinery, it is vital to consider several key features that directly impact performance and efficiency. One of the most critical factors is the cylinder's construction material. High-quality cylinders are often made from durable steel or aluminum, designed to withstand high pressures and reduce the risk of corrosion. According to a report by the Machinery Research Institute, the use of advanced synthetic materials can enhance the lifespan of hydraulic cylinders by up to 40%, significantly reducing maintenance and replacement costs.

Another essential feature is the cylinder's sealing system. Effective seals prevent hydraulic fluid leaks, which can lead to reduced efficiency and increased operating costs. Modern hydraulic oil cylinders often use advanced sealing technologies, such as polyurethane or PTFE seals, which offer better resistance to wear and tear. Industry studies indicate that the right sealing system can improve overall system performance by at least 25%, emphasizing the importance of selecting a cylinder that incorporates these innovations. Lastly, the compatibility of the hydraulic oil with the cylinder materials should not be overlooked. Proper compatibility ensures optimum fluid dynamics, enhancing the overall effectiveness and reliability of your heavy machinery.

Why You Need the Right Hydraulic Oil Cylinder for Your Heavy Machinery - Key Features to Look For in Hydraulic Oil Cylinders

| Key Features | Importance | Specifications | Maintenance Tips |

|---|---|---|---|

| Quality of Seals | Prevents leaks and ensures long service life. | High-grade rubber or polyurethane seals. | Regularly inspect seals for wear and replace as needed. |

| Bore Surface Finish | Reduces friction and wear on hydraulic rods. | Ra value of 0.2µm to 0.8µm for optimal performance. | Ensure proper lubrication to maintain smooth operation. |

| Pressure Rating | Determines the cylinder's lifting capacity. | Common ratings range from 1500 psi to 5000 psi. | Avoid exceeding recommended pressure limits. |

| Material Construction | Ensures durability and resistance to harsh conditions. | Steel and aluminum are common materials. | Inspect for corrosion or damage regularly. |

| Port Configuration | Facilitates fluid transfer in the hydraulic system. | Standard inlet and outlet sizes like SAE and NPT. | Ensure compatibility with existing hydraulic lines. |

Common Types of Hydraulic Oil Cylinders for Heavy Machinery

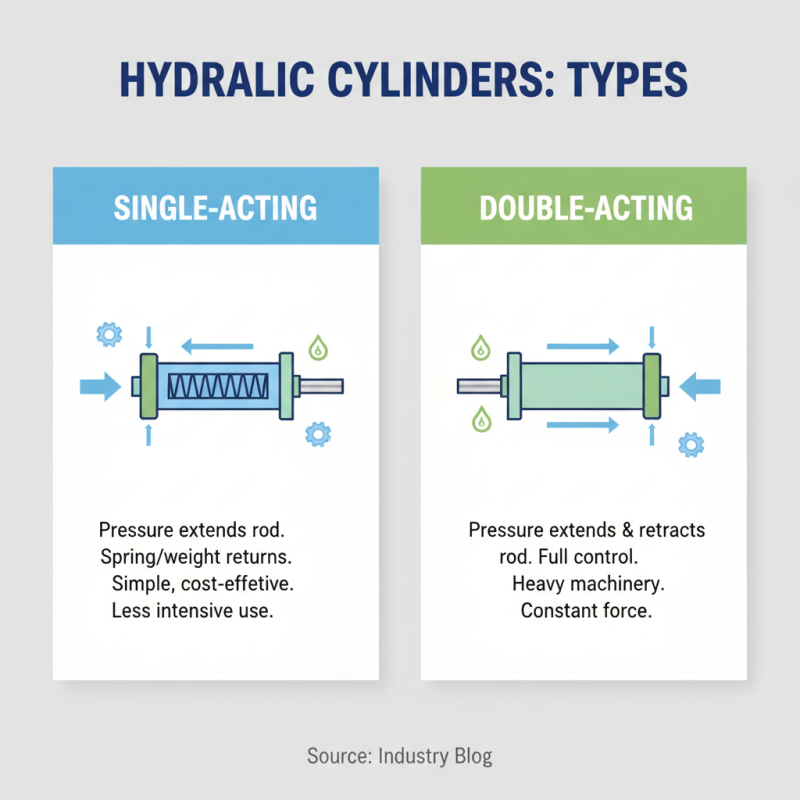

Hydraulic oil cylinders are essential components in heavy machinery, providing the necessary force to lift, push, or pull loads. Understanding the common types of hydraulic oil cylinders can help operators make informed choices when selecting the right cylinder for their equipment. The most prevalent types include single-acting and double-acting cylinders. Single-acting cylinders use hydraulic pressure to move in one direction and are often used in applications where the return motion is controlled by a spring or weight. This design is simple and cost-effective, making it suitable for less intensive applications.

On the other hand, double-acting cylinders offer versatility by enabling movement in both directions using hydraulic fluid. This design makes them ideal for tasks that require a constant and controlled force, such as lifting heavy machinery components or operating heavy equipment like excavators and forklifts. Additionally, specialized cylinders such as telescopic and rotary cylinders exist for specific applications. Telescopic cylinders are capable of extending multiple stages, providing a significant reach in confined spaces, while rotary cylinders allow for controlled rotational movements, critical in applications requiring precise maneuverability. Understanding these types can significantly enhance performance and efficiency in heavy machinery operations.

Impact of Hydraulic Oil Quality on Machinery Performance

The quality of hydraulic oil plays a crucial role in the overall performance of heavy machinery. Hydraulic systems rely on oil not only as a lubricant but also as a medium for transferring energy. Poor-quality hydraulic oil can lead to increased friction, which may cause components to wear out prematurely and compromise the efficiency of the machinery. With contaminants like dirt and water entering subpar hydraulic oil, the risk of pump failure and system breakdown rises significantly, leading to costly downtime and repairs.

Furthermore, the viscosity and thermal stability of hydraulic oil directly impact the operational effectiveness of heavy machinery. If the oil is too thick or too thin, it can adversely affect the response times of hydraulic cylinders and motors, resulting in sluggish or erratic behavior. High-quality hydraulic oils are engineered to maintain optimal viscosity across a range of temperatures, ensuring that machinery operates smoothly and reliably under various conditions. Investing in superior hydraulic oil not only enhances performance but also prolongs the lifespan of the machinery, ultimately leading to increased productivity and reduced maintenance costs.

Impact of Hydraulic Oil Quality on Heavy Machinery Performance

Maintenance Tips for Prolonging Hydraulic Oil Cylinder Lifespan

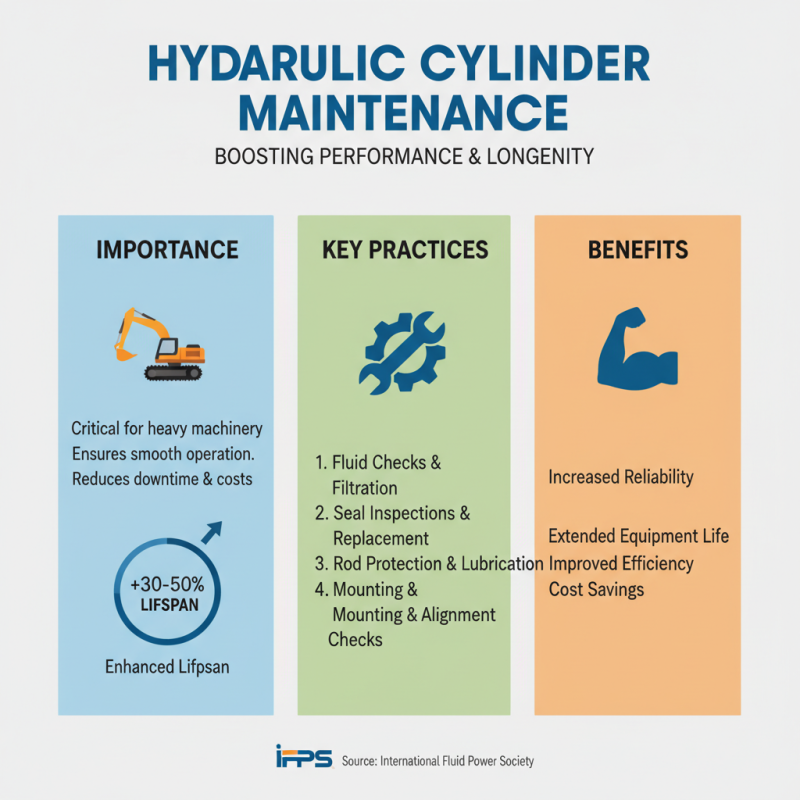

Hydraulic oil cylinders are crucial components in heavy machinery, serving as the backbone for various operations in construction, manufacturing, and other industries. To ensure optimum performance and longevity of these systems, regular maintenance practices are essential. According to the International Fluid Power Society, proper maintenance can enhance the lifespan of hydraulic components by 30-50%, significantly reducing cost implications associated with equipment downtime and replacements.

One effective maintenance tip involves regular inspection of the hydraulic oil for contamination and degradation. The presence of particulates or moisture can lead to increased wear and tear on cylinder seals, potentially causing leaks and system failures. Implementing a routine oil analysis can help identify issues early, allowing for timely interventions. Additionally, maintaining the correct oil temperature is vital, as hydraulic fluids have specific viscosity requirements that are temperature-dependent. Keeping the system within an optimal temperature range reduces stress on the hydraulic oil, enhancing its performance and extending the life of the cylinder.

Proper storage of hydraulic oil is equally important. Exposure to environmental contaminants can degrade oil quality, leading to premature failure of hydraulic systems. By following best practices in oil storage and ensuring regular oil changes, operators can maintain the efficacy of hydraulic oil cylinders. Reports from the Fluid Power Journal indicate that adherence to these maintenance protocols not only improves performance but can also lead to a decrease in overall operational costs by up to 20%.

Related Posts

-

Maximizing Efficiency: The Advantages of Upgrading Your Hydraulic Oil Cylinder Systems

-

Ultimate Guide to Choosing the Best Hydraulic Oil Cylinder for Your Needs

-

Top Strategies for Enhancing Performance of Hydraulic Oil Cylinders

-

7 Solid Reasons to Choose Hydraulic Oil Cylinders for Your Industrial Needs

-

A Comprehensive Guide to Selecting the Best Hydraulic Cylinder for Your Trailer Needs

-

Essential Checklist for Selecting the Right Hydraulic Oil Cylinder for Your Needs