Maximizing Efficiency and Performance with Telescopic Cylinder Innovations in the Hydraulic Industry

In recent years, the hydraulic industry has witnessed remarkable innovations, particularly in the design and functionality of Telescopic Cylinders. As a pivotal component in numerous applications, ranging from construction equipment to mobile machinery, the efficiency and performance of these hydraulic systems are critical. According to a report by MarketsandMarkets, the global hydraulic cylinder market is projected to reach $9.5 billion by 2027, driven by technological advancements and the growing demand for high-efficiency equipment.

Telescopic Cylinders, with their ability to compress into smaller spaces while providing extended reach and force capability, have become essential in maximizing operational productivity. By implementing the latest design improvements and materials, companies can achieve significant enhancements in their hydraulic systems, thereby lowering operational costs and increasing overall performance in a competitive market landscape. Understanding how to leverage these innovations effectively can provide industry players with the tools needed to thrive in a rapidly evolving sector.

Understanding Telescopic Cylinder Basics in Hydraulic Systems

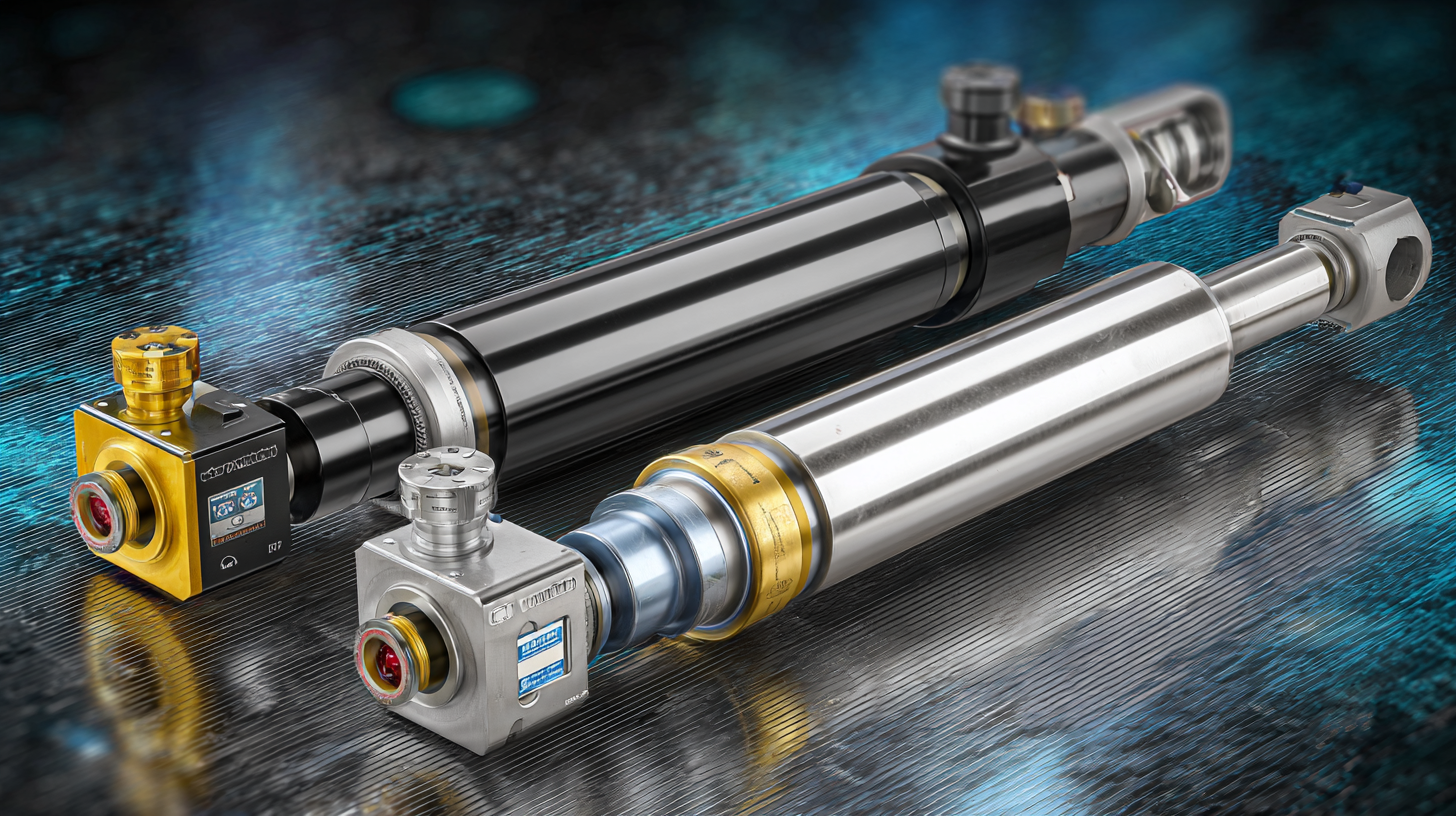

Telescopic cylinders are critical components in hydraulic systems, offering a unique solution for applications requiring long stroke lengths in a compact form. They consist of multiple nested cylinders, allowing for significant extension without requiring a substantial amount of space. This design is particularly advantageous in industries such as construction and transportation, where space constraints often pose challenges. By efficiently utilizing hydraulic fluid, telescopic cylinders can extend to various lengths with minimal energy consumption, making them an effective choice for maximizing operational efficiency.

Understanding the operational principles of telescopic cylinders is essential for optimizing their performance in hydraulic systems. When hydraulic fluid is introduced into the cylinder, it creates pressure that forces the inner cylinders to extend sequentially. This action not only allows for a greater reach but also provides controlled movements essential for tasks like lifting and positioning heavy loads. The ability to retract fully when not in use offers significant versatility. Consequently, operators must ensure proper maintenance and selection of materials to prevent wear and tear, ensuring longevity and reliability in demanding environments.

Key Innovations Driving Efficiency in Telescopic Cylinder Design

The landscape of the hydraulic industry is rapidly evolving, driven by significant innovations in telescopic cylinder design. One key innovation is the introduction of advanced materials that enhance durability while reducing weight. These materials not only improve the overall efficiency of the telescopic cylinders but also extend their service life, making them more cost-effective over time. The ability to withstand higher pressures without compromising performance has made new designs especially appealing for applications that require both strength and precision.

Another critical advancement is the incorporation of smart technology into telescopic cylinders. By integrating sensors and IoT capabilities, manufacturers can monitor performance in real-time, diagnosing issues before they become critical. This level of insight allows for predictive maintenance, ultimately minimizing downtime and enhancing operational efficiency. Additionally, the development of optimized hydraulic fluids tailored for these innovations ensures smoother operation and better responsiveness, further amplifying the benefits of modern telescopic cylinders in various hydraulic applications.

Maximizing Efficiency and Performance with Telescopic Cylinder Innovations in the Hydraulic Industry

| Innovation | Description | Impact on Efficiency (%) | Usage in Industry |

|---|---|---|---|

| Compact Design | Reduced overall dimensions allowing for easier integration in tight spaces. | 15% | Construction, Automotive |

| Advanced Sealing Technology | Improved sealing performance reduces leakage and enhances durability. | 20% | Mining, Agriculture |

| Weight Optimization | Use of lightweight materials to improve lift capacity and reduce energy consumption. | 25% | Logistics, Transportation |

| Smart Sensors Integration | Real-time monitoring of performance leads to predictive maintenance. | 30% | Manufacturing, Robotics |

| Enhanced Stroke Control | Precision control mechanisms for improved operational performance. | 18% | Construction, Marine |

Optimizing Performance: Choosing the Right Telescopic Cylinder for Your Application

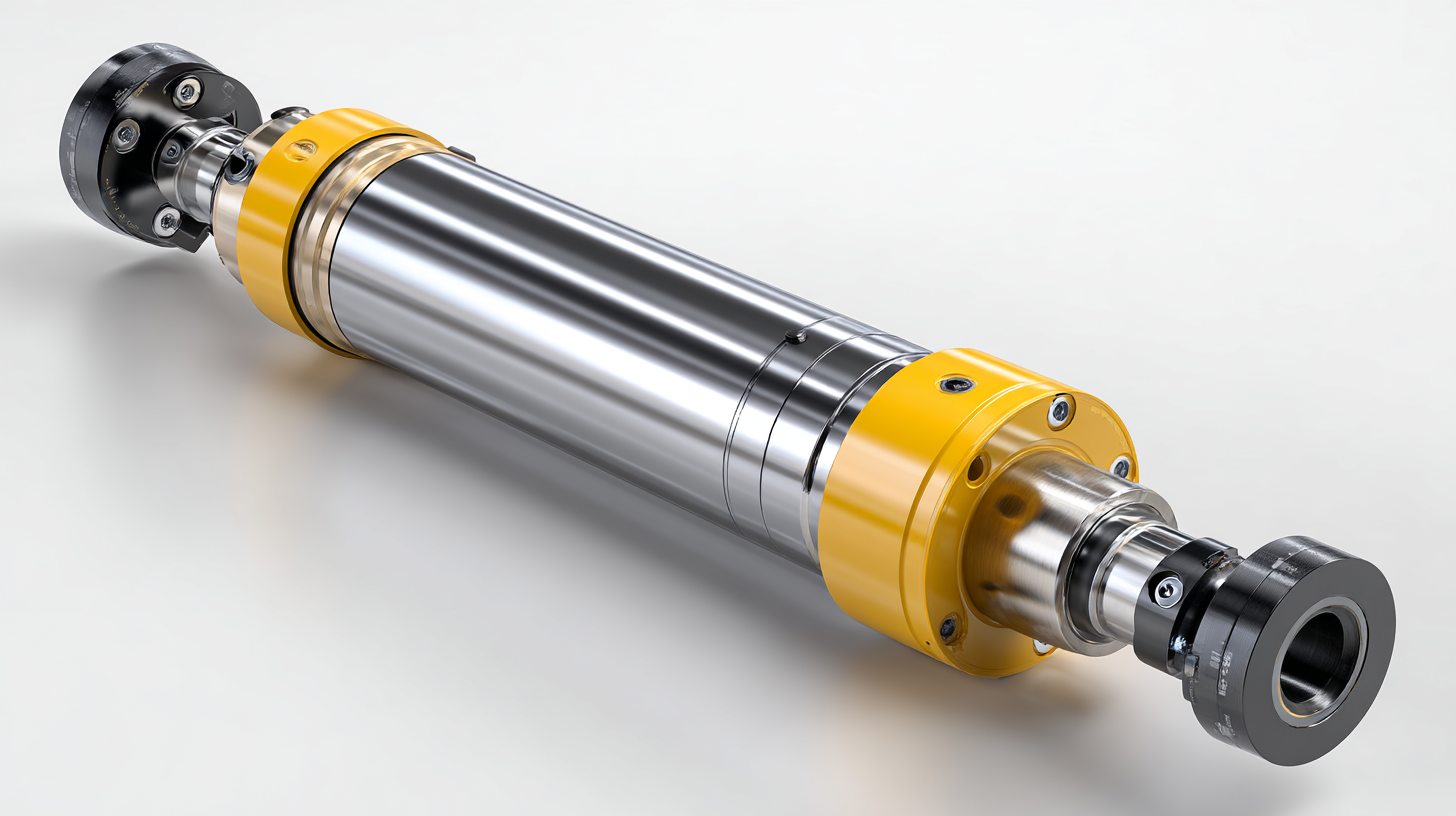

When selecting a telescopic cylinder for a specific application, understanding the unique requirements of your project is essential for optimizing performance. Telescopic cylinders, renowned for their compact design and extended reach, are ideal for applications such as construction, transportation, and material handling. Factors such as load capacity, stroke length, and mounting style need to be carefully considered to ensure the cylinder can handle the operational demands without compromising efficiency.

Additionally, material selection and seal compatibility play a crucial role in the longevity and reliability of telescopic cylinders. Choosing the right materials can help resist wear and tear in harsh environments, while appropriate seal types prevent leakage and protect against contaminants. By aligning the cylinder specifications with application needs, users can significantly enhance the overall performance and durability of hydraulic systems, leading to improved productivity and reduced maintenance costs in the long run.

Maximizing Efficiency and Performance with Telescopic Cylinder Innovations

Maintenance Best Practices for Enhanced Performance of Telescopic Cylinders

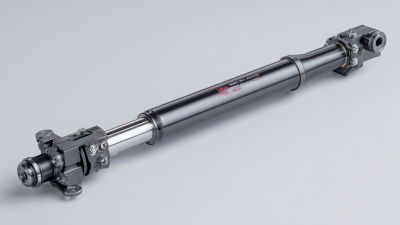

Telescopic cylinders are essential components in various hydraulic systems, enabling efficient operation across industries such as construction and materials handling. To maximize their performance, implementing best maintenance practices is crucial. According to a report by the International Society for Fluid Power, approximately 40% of hydraulic system failures are attributed to insufficient maintenance, underscoring the importance of regular inspections and proactive measures.

Regular maintenance tasks should include checking seals and ensuring proper lubrication, as these factors significantly affect the cylinder's performance and lifespan. A well-maintained telescopic cylinder can improve overall system efficiency by as much as 30%, as inefficient systems often lead to increased energy consumption and downtime. Moreover, implementing condition monitoring techniques can help predict potential issues before they escalate into costly repairs, allowing operators to replace components strategically, ultimately leading to reduced operational costs.

Furthermore, adhering to manufacturer guidelines for maintenance schedules is imperative. The Hydraulic Institute's guidelines suggest that routine maintenance can extend the life of hydraulic components by up to 50%. By prioritizing these practices, organizations can achieve not only enhanced performance from their telescopic cylinders but also significant cost savings and operational efficiency.

Future Trends in Telescopic Cylinder Technology and Their Impact on the Industry

The future of telescopic cylinder technology is poised for transformative advancements, driven by the increasing demand for efficiency and performance in the hydraulic industry. As the long stroke hydraulic cylinder market is projected to grow from USD 2.8 billion in 2024 to USD 4.5 billion by 2033, innovations in telescopic designs will play a crucial role. These cylinders are becoming essential for large-scale applications, providing enhanced reach and compact design, which is particularly beneficial in construction, material handling, and other sectors requiring high power in limited spaces.

Moreover, emerging technology trends will significantly influence the evolution of telescopic cylinders. The integration of artificial intelligence into hydraulic systems promises to optimize performance through predictive maintenance, ensuring minimal downtime and improved operational efficiency. As companies increasingly focus on sustainability and automation, the adaptability of telescopic cylinders to integrate smart technologies will be a key factor in driving industry growth. This evolution not only enhances the operational capabilities of hydraulic systems but also aligns with the broader technological advancements anticipated in the coming years, marking a pivotal change in how the industry approaches design and functionality.

Related Posts

-

Top 5 Best Telescopic Cylinders: A Comparative Review for Optimal Performance

-

7 Essential Tips for Choosing the Right Telescopic Cylinder

-

Unmatched Quality in Telescopic Cylinders Shaping Global Manufacturing Excellence from China

-

The Ultimate Guide to Understanding Telescopic Cylinders Underbody Applications and Benefits

-

The Ultimate Guide to Sourcing Telescopic Cylinders Underbody for Global Buyers

-

Ultimate Guide to Mastering Telescopic Cylinders Underbody for Enhanced Performance