How to Maximize Efficiency with Telescopic Cylinders in Heavy Machinery Operations

In the realm of heavy machinery operations, the efficiency and effectiveness of equipment play a pivotal role in overall productivity and performance. One key component that significantly enhances operational capabilities is the Telescopic Cylinder. These advanced hydraulic systems provide the ability to extend and retract, allowing machinery to achieve greater reach and versatility while maintaining compact size. As industries continuously seek to optimize workflows and reduce downtime, understanding how to maximize the performance of telescopic cylinders becomes crucial. This guide will explore various strategies and best practices for integrating telescopic cylinders into heavy machinery operations, ensuring that operators can harness their full potential to improve efficiency, safety, and productivity in their daily tasks. By leveraging the unique advantages of telescopic cylinders, companies can achieve remarkable advancements in their operational processes.

Understanding the Basics of Telescopic Cylinders in Heavy Machinery

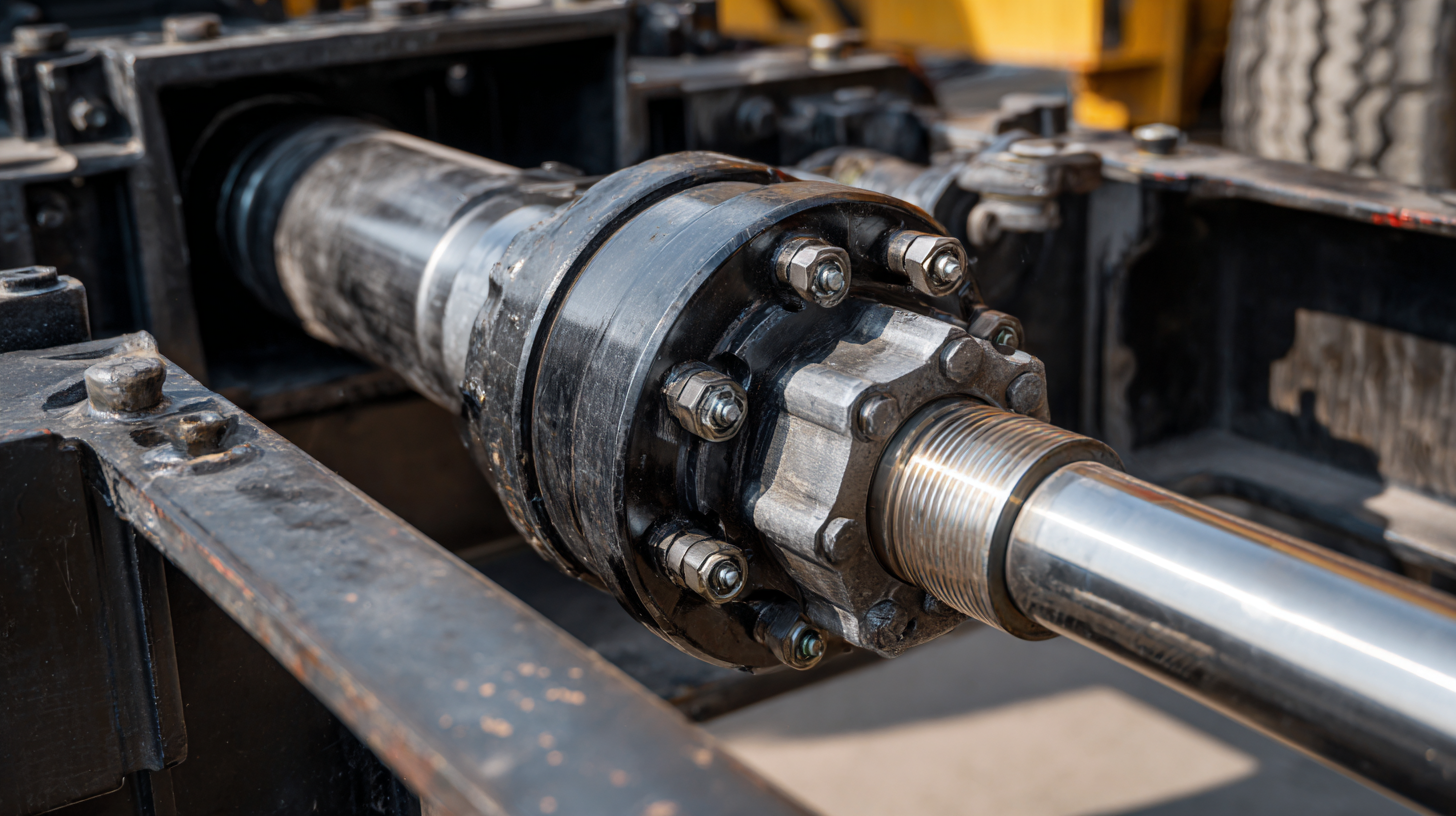

Telescopic cylinders are integral components in heavy machinery, offering significant advantages in space-saving and operational efficiency. These hydraulic devices consist of multiple nested sections that extend and retract, allowing for considerable stroke lengths without requiring excessive vehicle space. Understanding their operation is essential for optimizing machine performance, as these cylinders can achieve various lifting and lowering tasks with precision and ease.

In heavy machinery applications, telescopic cylinders are commonly employed in dump trucks, excavators, and lifts. Their design allows for maximum force while maintaining a compact structure, which is particularly beneficial in environments where maneuverability is crucial. By utilizing telescopic cylinders effectively, operators can not only enhance lifting capabilities but also improve overall cycle times, leading to increased productivity on job sites. Knowledge of these cylinders’ functionality, maintenance needs, and specific application scenarios plays a vital role in ensuring they are used to their full potential.

Key Applications of Telescopic Cylinders in Various Industries

Telescopic cylinders play a crucial role in various industries, enhancing the functionality and efficiency of heavy machinery. These devices are widely utilized in construction, agriculture, and transportation, where they provide powerful and compact lifting solutions. In construction, telescopic cylinders are essential for extending booms on cranes and excavators, allowing for greater reach and versatility in tight spaces. In the agricultural sector, they power equipment such as hay balers and loaders, enabling efficient material handling. Similarly, in transportation, telescopic cylinders assist in the movement and elevation of trailers and containers, streamlining loading and unloading processes.

To maximize the efficiency of telescopic cylinders, it's essential to conduct regular maintenance. Ensure that seals and connections are checked frequently to avoid leakage, which can lead to loss of hydraulic pressure and equipment failure. Additionally, operators should be trained to operate machinery with telescopic cylinders properly, focusing on gradual and controlled movements to prevent sudden impacts that could damage the equipment.

When integrating telescopic cylinders into heavy machinery operations, consider the operational environment and choose cylinders with appropriate load ratings and stroke lengths. Properly sizing the cylinders can enhance efficiency and prevent strain on machinery, ensuring smooth and reliable performance across various applications.

Strategies to Optimize Performance of Telescopic Cylinders

Telescopic cylinders are essential components in heavy machinery operations, providing the necessary force and reach for various applications. To optimize their performance, regular maintenance is crucial. Inspecting seals and lubrication frequently can prevent leaks and wear, ensuring the cylinders operate smoothly and efficiently. Keeping the cylinders free from dirt and debris will avoid contamination that can lead to premature failures.

Telescopic cylinders are essential components in heavy machinery operations, providing the necessary force and reach for various applications. To optimize their performance, regular maintenance is crucial. Inspecting seals and lubrication frequently can prevent leaks and wear, ensuring the cylinders operate smoothly and efficiently. Keeping the cylinders free from dirt and debris will avoid contamination that can lead to premature failures.

Another strategy to enhance the efficiency of telescopic cylinders is to utilize appropriate hydraulic fluid. Selecting the right viscosity and type of fluid tailored for specific operating conditions can improve responsiveness and performance. Additionally, implementing advanced control systems allows for better monitoring of the cylinder's operation, enabling timely adjustments of pressure and flow rates for optimal performance under varying loads. Integrating these strategies contributes significantly to maximizing the effectiveness of telescopic cylinders in heavy machinery, ultimately leading to improved operational outcomes.

Maintenance Best Practices for Prolonging Cylinder Lifespan

To ensure the longevity and optimal performance of telescopic cylinders in heavy machinery, adhering to maintenance best practices is crucial. Industry reports suggest that regular maintenance can extend the lifespan of hydraulic cylinders by up to 50%, significantly reducing downtime and repair costs. According to a study by the National Fluid Power Association, approximately 30% of hydraulic system failures are attributed to inadequate maintenance practices.

Routine inspections should include checking for leaks, verifying proper lubrication levels, and assessing for signs of wear or corrosion. Utilizing high-quality lubricants and adhering to specified service intervals can prevent premature deterioration. Additionally, keeping the cylinders free from contaminants is imperative; even small particles can lead to significant wear and damage, potentially increasing maintenance expenditures.

With more than 25% of machinery downtime linked to hydraulic system issues, implementing a proactive maintenance strategy is essential for maximizing efficiency and ensuring operational reliability in heavy machinery operations.

Innovative Technologies Enhancing Telescopic Cylinder Efficiency

Telescopic cylinders play a crucial role in heavy machinery operations by providing powerful, extendable force in a compact design, which is essential for various lifting and pushing tasks. Recent innovations in hydraulic technologies have significantly enhanced the efficiency of these cylinders, making them more reliable and easier to integrate into operational workflows. For instance, advanced materials and sealing technologies have improved the durability and performance of telescopic cylinders, allowing them to withstand increased pressure and environmental wear.

**Tips for Maximizing Efficiency:**

1. Regular Maintenance: Implement a routine maintenance schedule to check for leaks and ensure all components are functioning optimally. This helps to prevent unexpected downtime and costly repairs.

2. Utilize Smart Sensors: Consider integrating smart sensors that can provide real-time data on the performance of the telescopic cylinders, enabling operators to make informed decisions and adjustments instantly.

3. Optimize Hydraulic Fluid Use: Ensure that the hydraulic fluid used is of high quality and appropriate for the specific conditions of your operation, as this can greatly affect the responsiveness and efficiency of the cylinders.

By embracing these innovative technologies and tips, heavy machinery operations can significantly boost productivity, reduce operational costs, and enhance overall machine longevity.

Efficiency of Telescopic Cylinders in Heavy Machinery Operations

Related Posts

-

How to Choose the Right Telescopic Cylinder for Your Industrial Needs

-

Ultimate Guide to Understanding Hydraulic Cylinders for Excavators in Global Markets

-

5 Best Features of Telescopic Cylinder You Must Know

-

7 Essential Tips to Maximize Efficiency with Hydraulic Oil Cylinders: Improve Performance by 30%!

-

Ultimate Guide to Mastering Telescopic Cylinders Underbody for Enhanced Performance

-

Innovative Solutions for Hydraulic Cylinder For Excavator Enhancing Performance and Longevity