Ultimate Guide to Mastering Telescopic Cylinders Underbody for Enhanced Performance

In the world of mechanical engineering and construction, the efficiency and reliability of equipment are paramount, especially when it comes to heavy machinery and vehicles. Among the critical components that play a pivotal role in enhancing performance is the "Telescopic Cylinders Underbody." These advanced hydraulic systems are designed to provide superior lifting capabilities and optimized space-saving solutions, making them indispensable for various applications. This ultimate guide aims to delve deep into the intricacies of telescopic cylinders underbody, exploring their design, functionality, and maintenance best practices. By mastering the key principles and techniques associated with these cylinders, operators and engineers alike can significantly improve the operational efficiency and longevity of their equipment.

Join us as we navigate through essential insights and practical tips, empowering you to harness the full potential of telescopic cylinders underbody for enhanced performance.

Understanding the Basics of Telescopic Cylinders for Underbody Applications

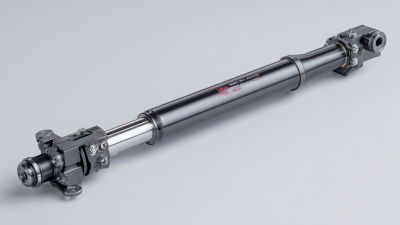

Telescopic cylinders are essential components in underbody applications, particularly in industries such as construction, automotive, and manufacturing. These hydraulic devices allow for the extension and retraction of machinery with remarkable precision and power. Understanding the basics of telescopic cylinders is crucial for optimizing their performance and ensuring their longevity in demanding environments. At the heart of their operation is the principle of hydraulic force multiplication, where a small input can generate significant movement, making them ideal for tasks like lifting heavy loads or adjusting the height of equipment.

Telescopic cylinders are essential components in underbody applications, particularly in industries such as construction, automotive, and manufacturing. These hydraulic devices allow for the extension and retraction of machinery with remarkable precision and power. Understanding the basics of telescopic cylinders is crucial for optimizing their performance and ensuring their longevity in demanding environments. At the heart of their operation is the principle of hydraulic force multiplication, where a small input can generate significant movement, making them ideal for tasks like lifting heavy loads or adjusting the height of equipment.

The construction of telescopic cylinders typically involves multiple stages or tubes that nest within one another. This design enables them to achieve impressive lengths while maintaining a compact size when retracted. The key to their effectiveness lies in the careful selection of materials and the engineering of seals that prevent hydraulic fluid leakage. Additionally, proper maintenance, such as regular inspection of seals and lubrication of moving parts, is essential to preserve their functionality and performance. As industries continue to seek efficiency and improved performance, mastering the fundamentals of telescopic cylinders will be vital for engineers and operators alike.

Key Factors Influencing Performance of Telescopic Cylinders

When it comes to enhancing the performance of telescopic cylinders, several key factors play a vital role. Understanding the design parameters is crucial, as the arrangement of the cylinder stages directly impacts the cylinder's overall stroke length and load capacity. By optimizing the number of stages, manufacturers can create a more efficient power-to-weight ratio, ultimately leading to improved machine performance.

Another significant factor is the choice of materials used in the construction of these cylinders. High-strength, lightweight materials not only reduce the overall weight but also contribute to durability and operational longevity. The surface finish of the hydraulic components can influence friction and seal wear, making advanced coatings essential for maintaining efficiency over time. Additionally, regular maintenance practices, including proper lubrication and seal inspection, are critical to ensure that telescopic cylinders remain reliable and perform at their best under demanding conditions.

Maintenance Tips for Longevity and Efficiency of Telescopic Cylinders

Telescopic cylinders are essential components in various industrial applications, providing the necessary power and efficiency for lifting heavy loads. To ensure their longevity and optimal performance, regular maintenance is crucial. According to a report by the International Society of Automation, proper maintenance can extend the lifespan of hydraulic cylinders by up to 50%. Therefore, implementing a robust maintenance plan is not just a best practice but a necessity for maximizing output.

One key maintenance tip is to regularly inspect and replace seals and O-rings. These components are critical in preventing leaks and maintaining pressure within the cylinder. A study by the Fluid Power Journal mentions that nearly 25% of hydraulic failures are attributed to seal damage, underscoring the importance of prompt inspections. Additionally, consistent lubrication can significantly reduce wear and tear, ensuring smooth operation and minimizing downtime.

Another important aspect is to monitor the hydraulic fluid quality. Contaminated fluid can lead to system inefficiencies and increased wear on internal components. The National Fluid Power Association recommends checking fluid condition and filters every 500 hours of operation. This proactive approach can catch potential issues early, preventing more significant problems down the line and ensuring that telescopic cylinders function at peak performance.

Innovative Solutions to Common Issues with Telescopic Cylinder Underbodies

When it comes to enhancing the performance of telescopic cylinders underbodies, understanding common issues and innovative solutions is key. One prevalent problem is the wear and tear due to environmental factors. Regular inspections and maintenance can prevent minor damages from escalating, ensuring that the telescopic cylinders function optimally.

Tips: To improve longevity, consider using protective coatings that shield against corrosion and debris. Additionally, implementing a routine maintenance schedule can help monitor the condition of the underbodies and identify potential problems early.

Another challenge is hydraulic fluid maintenance. The quality of hydraulic fluid directly impacts the efficiency of the system. Contaminated or degraded fluid can lead to performance issues. Using high-quality hydraulic fluids and regularly checking for leaks can drastically improve performance.

Tips: Invest in a hydraulic fluid filtration system to keep fluids clean and maintain optimal performance. Regularly monitoring fluid levels and conditions will also help in sustaining the life of the cylinders. By paying attention to these crucial aspects, the performance of telescopic cylinders underbodies can be significantly enhanced.

Future Trends in Telescopic Cylinder Technology and Performance Enhancements

The future of telescopic cylinder technology is poised for remarkable advancements, enhancing both performance and reliability in automotive applications. As vehicles increasingly incorporate sophisticated suspension systems to improve ride quality, the role of telescopic cylinders becomes critical. These components not only contribute to better handling and stability but also play a vital role in integrating new powertrains, such as those that feature innovative technologies like variable compression ratios. The ability of telescopic cylinders to adapt to varying loads will be essential as manufacturers aim for improved efficiency and performance.

As seen in recent automotive developments, the incorporation of advanced engineering in vehicle design is already influencing the market landscape. Innovations such as turbocharged engines are being paired with enhanced suspension technologies to create a seamless interaction between power and handling. This trend underscores the importance of mastering telescopic cylinder applications to accommodate diverse powertrains and driving conditions. With ongoing research and development, the telescopic cylinder sector is set to evolve, paving the way for vehicles that not only meet but exceed contemporary performance expectations.

Ultimate Guide to Mastering Telescopic Cylinders Underbody for Enhanced Performance

Related Posts

-

The Ultimate Guide to Sourcing Telescopic Cylinders Underbody for Global Buyers

-

The Ultimate Guide to Understanding Telescopic Cylinders Underbody Applications and Benefits

-

Essential Tips for Identifying Reliable Manufacturers of Best Telescopic Cylinders Underbody

-

Top 5 Best Telescopic Cylinders: A Comparative Review for Optimal Performance

-

7 Essential Tips for Choosing the Right Telescopic Cylinder

-

Unmatched Quality in Telescopic Cylinders Shaping Global Manufacturing Excellence from China