Innovative Advances in Telescopic Cylinder Technology Driving Efficiency in Industrial Applications

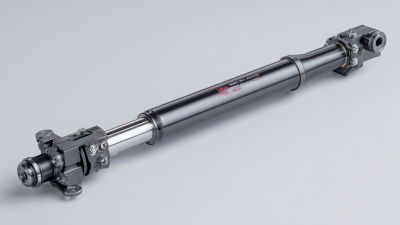

In recent years, the industrial sector has witnessed a remarkable transformation driven by innovative advances in Telescopic Cylinder technology. These hydraulic components are increasingly recognized for their ability to enhance efficiency and reliability across a variety of applications, from construction machinery to material handling equipment. According to a report by Research and Markets, the global hydraulic cylinders market is projected to reach USD $30 billion by 2025, indicating a significant growth rate that underscores the rising demand for specialized products like telescopic cylinders. With their compact design and ability to extend their length to handle heavy loads, these cylinders not only improve space management but also reduce operational costs. The integration of smart technology into telescopic cylinders further positions them as critical components in the push towards automation and increased productivity within industrial frameworks. As industries adapt to these advancements, the importance of telescopic cylinders will only continue to grow, becoming a cornerstone of modern engineering solutions.

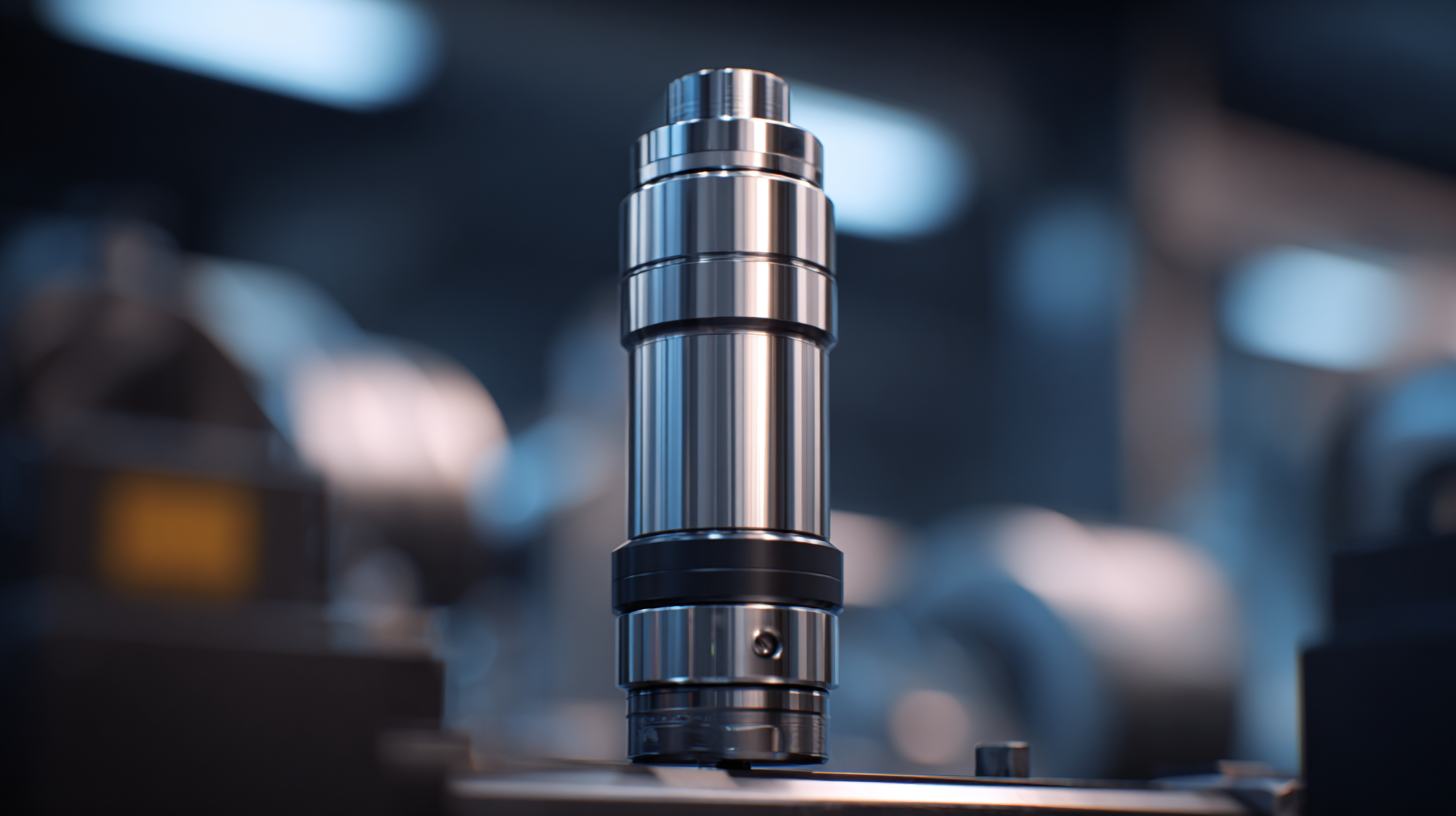

Innovative Materials in Telescopic Cylinder Design Enhancing Durability and Performance

The development of innovative materials in telescopic cylinder design has significantly enhanced their durability and performance, revolutionizing industrial applications. Traditionally, telescopic cylinders have faced challenges related to wear and tear, leading to frequent maintenance and replacements. However, with the introduction of advanced materials such as high-strength alloys and composite materials, modern telescopic cylinders now exhibit improved resistance to corrosion, temperature fluctuations, and mechanical stress. These advancements not only extend the lifespan of the cylinders but also reduce operational downtime, creating a more efficient workflow in various industries.

In addition to durability, these innovative materials contribute to the overall performance of telescopic cylinders. Lighter and stronger than their predecessors, they enable greater lifting capacity and more precise control. This improvement directly translates to enhanced productivity, as machinery can perform tasks more swiftly and efficiently. The integration of smart materials that respond to environmental changes is also paving the way for future developments, allowing for real-time adjustment in performance based on operational conditions. As industries continue to embrace these advancements, the potential for enhanced efficiency and operational excellence remains enormous.

Precision Engineering: How Advanced Manufacturing Techniques Improve Telescope Cylinders

Innovative manufacturing techniques have revolutionized the production of telescopic cylinders, enhancing their precision and efficiency in various industrial applications. Advanced methods such as additive manufacturing and CNC machining allow for tighter tolerances and improved material properties, significantly reducing the potential for failure under stress. These techniques enable manufacturers to create complex geometries that traditional methods struggle to achieve, resulting in lightweight and robust telescope cylinders that can perform under demanding conditions.

Furthermore, the integration of automation and advanced materials plays a crucial role in increasing the operational efficiency of telescopic cylinders. By employing smart manufacturing solutions that incorporate robotics and artificial intelligence, production processes have become more streamlined and less prone to human error. This not only accelerates production timelines but also enhances the overall quality of the final product. As industries continue to seek ways to optimize operations and reduce downtime, these advanced manufacturing techniques are setting new standards for performance in telescopic cylinder technology.

The Role of Automation in Maximizing Telescopic Cylinder Efficiency in Industrial Settings

The integration of automation in industrial settings has significantly enhanced the efficiency of telescopic cylinder technology. Telescopic cylinders, known for their compact design and high lifting capabilities, are becoming essential in various applications, including construction and material handling. By incorporating automated systems, industries are able to achieve precise control over these cylinders, minimizing human error and increasing operational speed. Automation enables real-time monitoring and adjustments, which are crucial for optimizing the performance of telescopic systems under varying loads and conditions.

Furthermore, automation allows for the synchronization of multiple telescopic cylinders, enhancing their collaborative functioning in assembly lines and other industrial processes. This not only improves productivity but also ensures safety by reducing the need for manual intervention in potentially hazardous environments. As industries continue to embrace Industry 4.0 principles, the role of automation in maximizing the efficiency of telescopic cylinders will likely expand, paving the way for smarter and more responsive industrial operations. With these innovative advancements, businesses can expect not only higher output but also reduced operational costs and improved reliability in their equipment.

Innovative Advances in Telescopic Cylinder Technology Driving Efficiency in Industrial Applications

| Application Area | Cylinder Type | Efficiency Gain (%) | Automation Level | Year of Adoption |

|---|---|---|---|---|

| Manufacturing | Single-Acting | 20% | High | 2022 |

| Construction | Double-Acting | 15% | Medium | 2021 |

| Logistics | Telescopic | 25% | Very High | 2023 |

| Agriculture | Compact | 10% | Low | 2020 |

| Waste Management | Heavy-Duty | 30% | High | 2022 |

Data-Driven Insights: Performance Metrics of Telescopic Cylinders across Various Industries

The evolution of telescopic cylinder technology has significantly enhanced operational efficiency across various industrial sectors, with performance metrics revealing compelling advantages. According to a recent report from the International Hydraulic Association, the use of high-efficiency telescopic cylinders can lead to a reduction in cycle times by up to 30%. This optimization not only streamlines workflow but also conserves energy, proving crucial in industries such as construction and material handling where hydraulic systems are fundamental.

Data from the Manufacturing Performance Institute highlights that companies implementing advanced telescopic cylinders have reported a 25% increase in lifting capacity and a 15% decrease in maintenance costs. These cylinders, designed for superior stability and strength, are becoming essential for applications in heavy duty operations, like waste management and mining. As industries continue to adopt data-driven approaches, the quantifiable benefits of utilizing modern telescopic cylinders underscore their role in driving productivity and achieving operational excellence.

Sustainability in Telescopic Cylinder Production: Reducing Waste and Increasing Energy Efficiency

Sustainability in the production of telescopic cylinders is becoming increasingly vital in response to the global push for eco-friendly manufacturing practices. By focusing on reducing waste, manufacturers are implementing advanced processes that streamline production and minimize excess material generation. Innovative techniques such as lean manufacturing and just-in-time inventory systems not only enhance efficiency but also significantly decrease the environmental footprint of telescopic cylinder manufacturing.

Additionally, energy efficiency plays a critical role in sustainable practices within this industry. The adoption of energy-efficient machinery and the utilization of renewable energy sources are key strategies that help mitigate carbon emissions during production. Companies are also exploring the use of lighter, more sustainable materials that not only reduce energy consumption but also contribute to overall product longevity. By integrating these practices, the telescopic cylinder sector is moving towards a more sustainable future, aligning industrial growth with environmental responsibility.

Related Posts

-

7 Essential Tips for Choosing the Right Telescopic Cylinder

-

The Ultimate Guide to Understanding Telescopic Cylinders Underbody Applications and Benefits

-

The Ultimate Guide to Sourcing Telescopic Cylinders Underbody for Global Buyers

-

Ultimate Guide to Mastering Telescopic Cylinders Underbody for Enhanced Performance

-

How to Choose the Right Telescopic Cylinders Underbody for Optimal Performance

-

Exploring Alternative Solutions for Telescopic Cylinders Underbody Applications