What is a Hydraulic Cylinder for Trailers? How It Works and Applications Explained

The hydraulic cylinder for trailers plays a pivotal role in the modern transportation and logistics industry, serving as the backbone of various loading and unloading operations. According to a recent report by the International Hydraulic Systems Association, the global market for hydraulic components, including cylinders, is forecasted to grow by 5% annually, highlighting the increasing demand for efficient and reliable hydraulic systems. This growth is largely propelled by the rising need for enhanced lifting capabilities and operational efficiency in various sectors, including construction, agriculture, and freight transport.

As noted by Dr. Emily Johnson, a leading expert in hydraulic systems, “The hydraulic cylinder for trailers is not just a component; it is a critical enabler of productivity in transport logistics." This statement underscores the importance of understanding how hydraulic cylinders operate and their applications across different industries. By leveraging the principles of fluid mechanics, these cylinders provide the necessary force to lift heavy loads, thus streamlining operations and reducing manual labor. With a focus on innovations and advancements in hydraulic technology, the industry is witnessing a transformation that promises to further enhance the performance of hydraulic cylinders in trailer applications.

What is a Hydraulic Cylinder for Trailers?

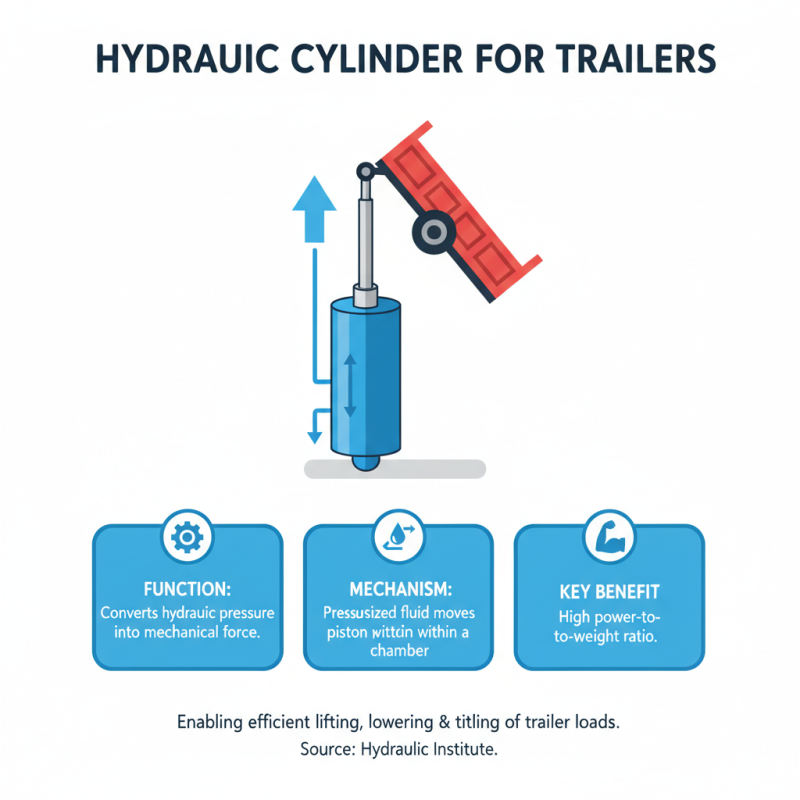

A hydraulic cylinder for trailers is a crucial component that converts hydraulic energy into mechanical force, enabling the lifting, lowering, and tilting of trailer loads. These cylinders utilize pressurized fluid to move a piston within a cylindrical chamber, allowing for smooth and efficient movement. According to the Hydraulic Institute's reports, hydraulic systems, including cylinders, are known for their high power-to-weight ratio, making them ideal for applications where strength and portability are necessary.

Hydraulic cylinders for trailers find applications in various industries, particularly in construction, agriculture, and transportation. They are commonly used in dump trailers to raise and lower the loading bed, ensuring that materials can be easily offloaded. Additionally, these cylinders are employed in tilt trailers that require precise angling to facilitate loading and unloading processes. Industry statistics indicate that the demand for hydraulic systems in the trailer sector is expected to grow by approximately 4.5% annually due to advancements in technology and increasing investment in infrastructure.

Tip: Regular maintenance of hydraulic cylinders is essential to ensure their longevity and efficiency. Checking the fluid levels and inspecting for leaks can prevent costly repairs and prolong the life of the hydraulic system. Keeping an eye on the piston seal condition will help maintain optimal performance.

Components of a Hydraulic Cylinder in Trailers

Hydraulic cylinders are essential components in trailers, serving as the primary mechanism for lifting, lowering, and moving heavy loads. A typical hydraulic cylinder consists of several key components, including the cylinder body, piston, rod, seals, and end caps. The cylinder body, usually made of high-strength steel, houses the hydraulic fluid and provides the structural integrity required to withstand high pressures. The piston, attached to the rod, is responsible for converting hydraulic pressure into mechanical force, enabling the cylinder to extend or retract depending on the fluid's movement.

One important aspect of hydraulic cylinders is their seals, which prevent leaks and ensure optimal performance. According to industry reports, the demand for hydraulic systems in trailers is expected to grow by 5% annually, driven by increases in transportation needs and advancements in hydraulic technology. Proper maintenance of these seals can significantly enhance the lifespan and efficiency of the hydraulic systems, reducing downtime during operations.

Tips: Regularly inspecting the hydraulic fluid levels and checking for leaks in the cylinder can prevent costly repairs and ensure smooth functionality. It's also recommended to follow manufacturer guidelines for service intervals to keep the hydraulic system in peak working condition. Additionally, using high-quality hydraulic fluid can improve performance and longevity of the cylinders.

What is a Hydraulic Cylinder for Trailers? How It Works and Applications Explained - Components of a Hydraulic Cylinder in Trailers

| Component | Description | Function | Applications |

|---|---|---|---|

| Cylinder Barrel | The main body of the hydraulic cylinder that contains hydraulic fluid. | Houses the piston and allows movement as fluid pressure changes. | Used in lifting and lowering trailer beds. |

| Piston | A cylindrical component that moves within the barrel. | Transforms hydraulic energy into mechanical force. | Critical for lifting loads on trailers. |

| Seals and Packing | Components that prevent fluid leakage. | Ensure efficient operation by maintaining pressure. | Essential for maintaining the integrity of hydraulic systems. |

| Ports | Inlets and outlets for hydraulic fluid. | Facilitate the flow of hydraulic fluid to and from the cylinder. | Critical for the operation of hydraulic systems in trailers. |

| Rod | A metal shaft that extends from the cylinder. | Transfers force from the piston to the trailer mechanism. | Used for lifting trailer hitches and hydraulic ramps. |

How Hydraulic Cylinders Work: The Mechanics Explained

Hydraulic cylinders are crucial components in trailers, enabling efficient lifting and lowering of loads. They function on the principle of hydraulics, which uses incompressible fluid to transmit force. When hydraulic fluid enters a cylinder through a port, it pushes against a piston inside. This pressure results in linear motion, allowing the trailer's load to be raised or lowered with remarkable ease and precision. The ability to control this motion makes hydraulic cylinders invaluable in various applications, from dump trailers to tilt beds.

When discussing the mechanics of hydraulic cylinders, it's essential to understand the significance of pressure and volume. The force generated by the piston is determined by the pressure of the hydraulic fluid and the surface area of the piston itself. As the fluid’s pressure increases, it can lift heavier loads. Moreover, the design of hydraulic cylinders, including the materials and seals used, plays a vital role in their efficiency and longevity. Regular maintenance is crucial to prevent leaks and ensure optimal performance.

**Tips:** When operating hydraulic cylinders, always check for leaks or signs of wear, as these can greatly affect performance. Additionally, ensure that the hydraulic fluid is at the proper level and is clean to maintain the system's efficiency. Familiarize yourself with the specific hydraulic system's specifications to optimize usage and enhance safety.

Hydraulic Cylinder Performance in Various Applications

Common Applications of Hydraulic Cylinders in Trailers

Hydraulic cylinders are pivotal components in trailer design, enabling efficient movement and control of heavy loads. One of the most common applications of these cylinders is in dump trailers, where they facilitate the raising and lowering of the trailer bed. According to a report from the International Truck & Trailer Manufacturers Association, the market for hydraulic systems in trailers is projected to grow by over 5% annually, largely driven by the increased demand for efficient loading and unloading operations in construction and agricultural sectors.

Another significant application of hydraulic cylinders in trailers is in tilt trailers, which are utilized for transporting machinery and vehicles. These cylinders allow for a smooth tilt of the trailer bed, improving accessibility for loading and unloading without the need for ramps. A recent industry analysis highlights that the adoption of tilt trailers with hydraulic systems has seen a 7% increase in the past few years, attributed to the ease of use and enhanced safety features they offer. This shows a clear trend towards more advanced hydraulic systems in trailer design, addressing the growing needs for versatility and efficiency in various transportation applications.

Maintenance Tips for Hydraulic Cylinders in Trailer Use

Proper maintenance of hydraulic cylinders in trailers is crucial for ensuring their reliable operation and longevity. According to a report by the International Hydraulics Association, approximately 70% of hydraulic system failures can be attributed to inadequate maintenance practices. Regular inspections and servicing can significantly reduce the risk of breakdowns, allowing for safer and more efficient trailer operations.

To maintain hydraulic cylinders effectively, it is essential to check for leaks regularly. Even minor leaks can lead to significant performance issues and hydraulic fluid loss, which can be costly. Additionally, keeping the cylinder and its components clean is vital. Dirt and contaminants can cause wear on seals and moving parts, leading to premature failure. Another key aspect is to regularly assess the hydraulic fluid quality. Fluid degradation can affect the operation of the system, so adhering to manufacturer recommendations for fluid replacement intervals is advised.

Furthermore, lubricating the moving parts of the hydraulic cylinder should not be overlooked. Industry studies indicate that proper lubrication can enhance performance and extend service life by up to 30%. Operators should also ensure that the mounting brackets and connection points are secure and free from corrosion, as these factors contribute to the overall stability and function of the hydraulic system. Taking these maintenance tips into account will help in maximizing the efficiency and safety of hydraulic cylinders used in trailers.

Related Posts

-

How to Choose the Best Hydraulic Cylinder for Your Trailer Needs

-

Top Strategies for Enhancing Performance of Hydraulic Oil Cylinders

-

Understanding the Functionality of Excavator Hydraulic Cylinders

-

7 Best Practices for Using Dump Truck Hydraulic Hoist Effectively

-

Ultimate Guide to Choosing the Right Hydraulic Cylinder for Excavators with Key Specs and Tips

-

How to Choose the Right Hydraulic Cylinder for Your Forklift Needs