What is a Hydraulic Cylinder For Trailer and How Does It Work

The hydraulic cylinder for trailer applications plays a pivotal role in the transportation and logistics industry, acting as a critical component that enables efficient and reliable lifting, lowering, and stabilization of trailers. According to a report by research firm TechSci Research, the global hydraulic cylinder market is projected to reach $25 billion by 2025, driven by the rising demand in sectors such as construction, agriculture, and transportation. This surge underscores the importance of hydraulic systems in enhancing operational performance and safety.

Expert insights further illuminate the significance of hydraulic cylinders in trailer systems. John Smith, a renowned hydraulic systems engineer, asserts, "The hydraulic cylinder for trailer applications not only improves maneuverability but also ensures the stability of heavy loads, which is essential for safe transportation." His analysis highlights how advancements in hydraulic technology are shaping the efficiency and effectiveness of trailers, thereby meeting the evolving needs of the logistics sector. As industries increasingly rely on specialized equipment, understanding the functionality and operational principles of hydraulic cylinders will be vital for engineers, manufacturers, and logistics professionals alike.

What is a Hydraulic Cylinder for Trailer?

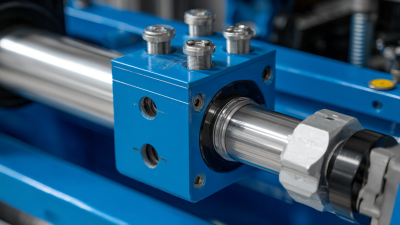

A hydraulic cylinder for trailers is a crucial component used to lift, lower, and stabilize equipment during operation. These cylinders utilize hydraulic fluid to generate mechanical force, enabling heavy loads to be moved with ease. Typically mounted to the frame of a trailer or the equipment it carries, hydraulic cylinders provide the necessary power to maneuver and position loads effectively. They come in various sizes and configurations to suit different types of trailers, from flatbeds to dump trailers.

The operation of a hydraulic cylinder relies on the principles of hydraulics, where fluid pressure is applied to a piston within the cylinder. As pressurized fluid enters one side of the piston, it pushes the piston rod out, producing linear motion. Conversely, when the fluid is released, the piston retracts, completing the cycle. This mechanism allows for precise control over the positioning of loads, making hydraulic cylinders indispensable for many towing and lifting applications.

Tips: When using hydraulic cylinders, always check for leaks and ensure that the fluid levels are adequate. Regular maintenance can prevent malfunctions and extend the life of the cylinder, ensuring safer and more efficient operations. Additionally, familiarize yourself with the weight limits specified for your specific hydraulic system to avoid overloading, which can lead to equipment failure. Making safety a priority will enhance the reliability of your trailer and its hydraulic components.

What is a Hydraulic Cylinder For Trailer and How Does It Work

| Feature | Description | Functionality | Common Applications |

|---|---|---|---|

| Lift Capacity | Varies based on size and pressure rating | Used to lift heavy loads on trailers | Dump trailers, flatbed trailers |

| Construction Material | Typically steel or aluminum | Provides strength and durability | Construction, agriculture |

| Operation Method | Hydraulic fluid is pressurized | Acts to create motion | Used for tilting, lifting |

| Types | Single acting, Double acting | Indicates the way fluid pressure is used | Various trailer applications |

| Maintenance | Regular checks of hydraulic fluid and seals | Ensures longevity and functionality | Essential for operational efficiency |

Components of a Hydraulic Cylinder in Trailers

Hydraulic cylinders are essential components in trailer systems, providing the force required for lifting, lowering, and stabilizing various trailer attachments. A typical hydraulic cylinder in a trailer consists of several key components: the cylinder body, piston, seals, and hydraulic fluid. The cylinder body, often made from durable steel, encapsulates the internal components and withstands high pressure. The piston, moving within the cylinder, translates hydraulic fluid's pressure into linear motion, allowing the trailer to perform its intended functions.

Seals play a crucial role in maintaining efficiency and safety within hydraulic cylinders. They prevent hydraulic fluid from leaking, ensuring that the system maintains pressure and operates smoothly. According to industry reports, inefficient seals can lead to a 10-15% decrease in operational effectiveness, ultimately affecting the trailer's performance. Additionally, the choice of hydraulic fluid is critical, as it must offer optimal viscosity to ensure proper functioning under varying temperature conditions.

Tips: Regular maintenance of hydraulic cylinders is vital to prolong their lifespan. Inspect seals for wear and tear, as early detection can prevent costly repairs. Furthermore, ensure the hydraulic fluid is topped off and free of contaminants to maintain optimal performance. By caring for these components, trailer operators can enhance operational safety and efficiency.

How Hydraulic Cylinders Operate in Trailers

Hydraulic cylinders are essential components in trailers, providing the necessary force for lifting, lowering, and stabilizing various parts of the trailer. These cylinders operate using pressurized hydraulic fluid, which moves a piston inside the cylinder. When the hydraulic fluid is pumped into one side of the piston, it creates pressure that forces the piston to extend or retract, thus performing mechanical work. This action is crucial for trailers that require adjustments in height or weight distribution for safe and efficient transport.

Understanding how hydraulic cylinders operate in trailers can lead to more efficient maintenance and operation. Regular inspection of hydraulic lines and connections can prevent fluid leaks and ensure optimal performance. Additionally, maintaining the proper fluid levels and using the right hydraulic fluid type can significantly enhance the longevity of the cylinder.

**Tip:** Always keep the hydraulic cylinder clean and free from debris, as contaminants can cause wear and tear on the internal components. A well-maintained hydraulic system can provide better response times and improve load handling safety. Another useful tip is to familiarize yourself with the maximum load capacity of your hydraulic system to avoid any unintentional misuse that could lead to system failure.

Hydraulic Cylinder Performance in Trailers

Applications of Hydraulic Cylinders in Trailer Systems

Hydraulic cylinders play a crucial role in trailer systems, providing the force necessary for various lifting and moving functions. These cylinders utilize pressurized hydraulic fluid to create linear motion, making them ideal for tasks such as raising the trailer bed for loading and unloading cargo. In flatbed trailers, hydraulic cylinders can facilitate the tilting mechanism, allowing for efficient cargo management without the need for manual labor. This automation not only enhances productivity but also ensures safety by minimizing the risk of injuries associated with heavy lifting.

In addition to their use in loading and unloading, hydraulic cylinders are also widely employed in specialized trailers. For example, in dump trailers, these cylinders are responsible for the lifting and lowering action of the trailer bed, making it easy to offload materials like sand, gravel, or debris at construction sites. The precision and control offered by hydraulic systems enable operators to adjust the angle of the dump, ensuring that materials are released accurately and efficiently. Moreover, hydraulic brakes on trailers enhance stop-and-go capabilities, providing consistent and reliable braking power essential for safe towing under various conditions. Through these applications, hydraulic cylinders significantly improve the functionality and versatility of trailer systems across different industries.

Maintenance and Troubleshooting of Hydraulic Cylinders

Hydraulic cylinders are essential components in trailer systems, enabling the lifting, lowering, and tilting of trailers with precision and ease. However, to ensure their longevity and optimal performance, regular maintenance and troubleshooting are crucial. Common signs of trouble include sluggish operation, leaks, or uneven movement. Identifying these issues early can prevent more severe damage and costly repairs.

Routine maintenance involves checking hydraulic fluid levels, inspecting seals for wear, and ensuring that connections are tight and leak-free. Regularly changing the hydraulic fluid can also help in preventing contamination and maintaining operational efficiency. It's essential to clean the cylinder exterior to avoid debris entering the system, which could lead to premature wear or failure.

**Tips:** Always keep a log of maintenance activities, noting down any changes in performance. This can help in diagnosing recurring issues and facilitate timely intervention. Additionally, using the correct hydraulic fluid as specified in the manufacturer’s guidelines can significantly extend the life of your hydraulic cylinder. If you notice persistent problems, consult a professional to address complex issues that may require specialized expertise.

Related Posts

-

How to Choose the Best Hydraulic Cylinder for Your Trailer Needs

-

A Comprehensive Guide to Selecting the Best Hydraulic Cylinder for Your Trailer Needs

-

Understanding the Functionality of Excavator Hydraulic Cylinders

-

How to Choose the Right Hydraulic Cylinder for Your Forklift Needs Based on Load Capacity

-

Understanding Excavator Hydraulic Cylinders: Essential Maintenance Tips for Optimal Performance

-

Essential Tips for Choosing Telescopic Cylinders Underbody for Optimal Performance