What is a Hydraulic Cylinder for Forklift and Its Importance?

In the world of material handling, the Hydraulic Cylinder for Forklift plays a crucial role. John Smith, an industry expert, stated, “The reliability of hydraulic systems defines the efficiency of a forklift.” This highlights the importance of understanding these components. A hydraulic cylinder enables forklifts to lift and move heavy loads with precision.

Hydraulic systems operate using fluid pressure to generate force. A well-functioning hydraulic cylinder ensures smooth operation. However, unexpected failures can occur. Regular maintenance is essential for avoiding potential breakdowns. Operators often overlook this aspect, leading to increased downtime.

The hydraulic cylinder's design is intricate, comprising seals, rods, and pistons. Each part must work cohesively for optimal performance. Inefficiencies in any component can result in major setbacks. Understanding the importance of these cylinders can enhance safety and productivity in the workplace.

What is a Hydraulic Cylinder in a Forklift?

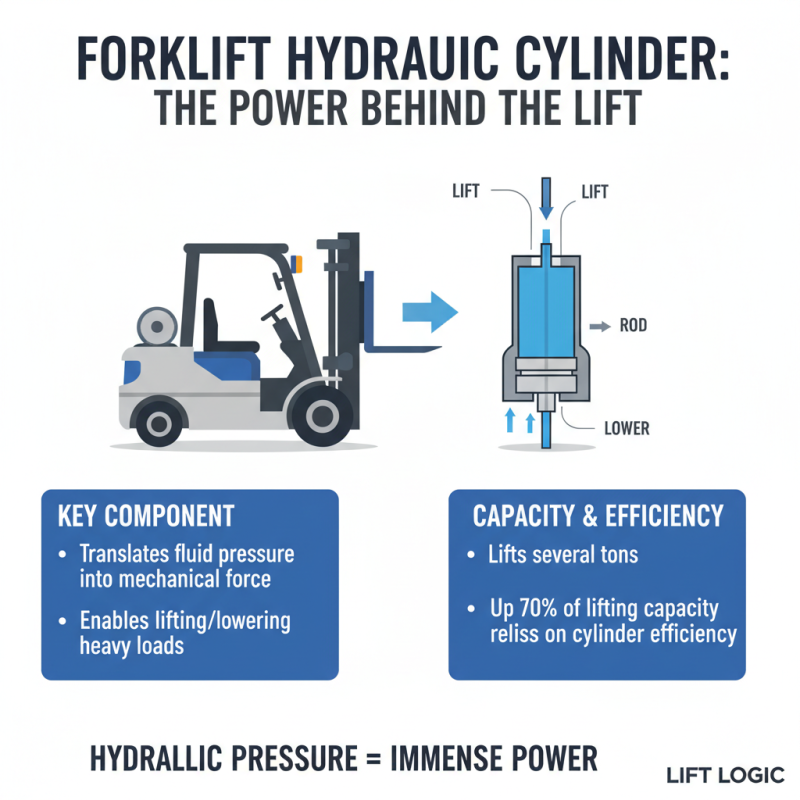

A hydraulic cylinder is a crucial component in a forklift, enabling it to lift and lower heavy loads efficiently. It operates on the basic principle of hydraulic pressure, translating fluid movement into mechanical force. This mechanism allows forklifts to handle weights that can exceed several tons. According to industry reports, up to 70% of a forklift's lifting capacity relies on the efficiency of its hydraulic cylinders.

In a typical hydraulic system, fluid is pushed into the cylinder, creating pressure that moves the piston. This action raises the fork assembly, enabling it to lift loads. The design and material of the hydraulic cylinder are critical. High-quality seals and robust construction materials can significantly reduce the risk of leaks. A worn cylinder can lead to reduced performance or even safety hazards. Industry studies indicate that up to 30% of forklift downtime is due to hydraulic system failures, highlighting the need for regular maintenance.

Attention to detail in the maintenance of hydraulic cylinders cannot be overstated. Operators should routinely check for leaks and pressure inconsistencies. Inadequate attention can lead to unexpected failures. These failures may compromise operations, causing unnecessary delays and potential accidents. Maintaining hydraulic cylinders is not just about performance; it’s also a matter of workplace safety.

How Hydraulic Cylinders Function in Forklift Operations

Hydraulic cylinders play a crucial role in forklift operations. They are responsible for lifting and lowering loads with precision. These cylinders are powered by hydraulic fluid, pressurized to create force. This process allows heavy objects to be moved easily and effectively.

When the operator engages the lift mechanism, hydraulic fluid travels into the cylinder. The pressure forces the cylinder rod to extend, lifting the load. This action is smooth yet powerful. However, if the hydraulic system is compromised, it can lead to performance issues. For example, leaks can reduce lifting capacity and slow operations.

Regular maintenance of hydraulic cylinders is essential. Operators should check for signs of wear, such as cracks or leaks. Ignoring these issues might lead to costly repairs or accidents. Understanding how hydraulic cylinders function is vital for efficient forklift operations. They are not just machines; they require attention and care.

Key Components of Hydraulic Cylinders in Forklifts

Hydraulic cylinders are vital components in forklifts, serving as the driving force behind lifting and lowering operations. These cylinders convert hydraulic energy into mechanical energy, allowing forklifts to handle heavy loads efficiently. The main components of hydraulic cylinders include the cylinder barrel, piston, seals, and rod. Each plays a crucial role in ensuring smooth operation and durability.

The design of the cylinder barrel is essential. It must withstand high pressure while remaining lightweight. The piston, fitted inside the barrel, engages with hydraulic fluid to create movement. Proper sealing prevents fluid leakage, which is crucial for maintaining performance. According to industry reports, hydraulic failures can lead to operational downtime. Regular maintenance is necessary to prevent such issues.

Tips: Always check for any signs of leaks or wear on seals during maintenance. Maintaining optimal hydraulic fluid levels is crucial for efficiency. Use appropriate fluid types recommended for your equipment to enhance performance. It’s important to reflect on the condition of your hydraulic components. Neglecting them could result in costly repairs and reduced productivity.

Importance of Hydraulic Cylinders for Forklift Performance

Hydraulic cylinders play a critical role in forklift performance. These components convert hydraulic pressure into mechanical force. This process allows forklifts to lift and lower heavy loads with ease. Without efficient hydraulic cylinders, a forklift’s capability is severely limited. Think about it: a forklift struggling to lift a load can slow down operations significantly.

Efficiency is key in any warehouse. When hydraulic cylinders perform optimally, operators can handle tasks quickly. A malfunctioning cylinder can lead to uneven lifting or even equipment failure. These issues can cause safety hazards and increase downtime. Frequent checks on hydraulic systems can identify potential problems before they arise.

While hydraulic cylinders enhance productivity, they also require proper maintenance. Neglecting regular service can lead to leaks and reduced performance. Operators need to be aware of the signs of wear and tear. Monitoring hydraulic fluid levels and checking for leaks is essential. This aspect often gets overlooked, yet it is vital for optimal operation.

What is a Hydraulic Cylinder for Forklift and Its Importance?

| Dimension | Description | Importance |

|---|---|---|

| Bore Diameter | The internal diameter of the cylinder where the hydraulic fluid acts. | Affects the force output and overall lifting capacity of the forklift. |

| Rod Diameter | The diameter of the piston rod extending from the cylinder. | Influences the strength and stability of the cylinder under load. |

| Stroke Length | The distance the piston travels within the cylinder. | Determines the lifting height and versatility of the forklift. |

| Operating Pressure | The maximum pressure that the hydraulic cylinder can operate under. | Affects the overall power and efficiency of the forklift. |

| Material | Commonly made from steel or aluminum for durability. | Ensures longevity and resistance to wear and tear in harsh conditions. |

Maintenance Tips for Hydraulic Cylinders on Forklifts

Hydraulic cylinders play a vital role in forklifts. They enable lifting and lowering heavy loads with precision. Proper maintenance of these cylinders is crucial for optimal performance. Regular inspections can prevent significant issues down the line. Look for leaks, as even small ones can indicate bigger problems. Check the seals and connections, too. Worn-out parts can lead to costly repairs.

Keeping the hydraulic fluid at the right level is important. Low fluid can cause the cylinder to malfunction. Flush the system regularly to remove debris. This helps maintain the efficiency of the hydraulic system. Without proper care, hydraulic cylinders may fail unexpectedly. Parts might wear out faster than anticipated, causing downtime.

Don't overlook signs of wear. Unusual noises during operation can signal trouble. Address these issues quickly to avoid accidents. It's easy to underestimate this aspect of forklift maintenance. Many operators focus on other parts and forget the hydraulic system. However, neglecting hydraulic cylinders can lead to operational hazards. Regularly assess and address any potential problems.

Related Posts

-

A Comprehensive Guide to Selecting the Best Hydraulic Cylinder for Your Trailer Needs

-

Ultimate Guide to Choosing the Best Hydraulic Oil Cylinder for Your Needs

-

Ultimate Checklist for Choosing the Right Hydraulic Cylinder for Your Forklift

-

Top Strategies for Enhancing Performance of Hydraulic Oil Cylinders

-

7 Solid Reasons to Choose Hydraulic Oil Cylinders for Your Industrial Needs

-

7 Essential Tips to Maximize Efficiency with Hydraulic Oil Cylinders: Improve Performance by 30%!