The Ultimate Guide to Understanding Telescopic Cylinders Underbody Applications and Benefits

The importance of telescopic cylinders underbody applications in various industries is increasingly recognized as a pivotal factor in enhancing operational efficiency and safety. According to a recent industry report from MarketsandMarkets, the global hydraulic cylinders market is projected to reach $16.5 billion by 2025, with a significant portion attributed to the growing demand for telescopic solutions due to their compact design and ability to extend in confined spaces. These innovative cylinders are critical in sectors such as construction, automotive, and logistics, where their capacity to support heavy loads while maintaining a smaller footprint is essential. As we delve into this ultimate guide, we will explore the various applications and benefits of telescopic cylinders underbody, providing insights that can help industry professionals optimize their operations and achieve greater productivity.

Overview of Telescopic Cylinders and Their Functionality

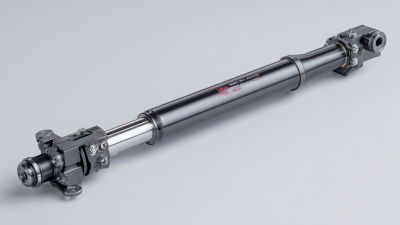

Telescopic cylinders are essential components in various industrial applications, primarily known for their ability to extend and retract in multiple stages. This design allows them to achieve significant movement in a compact space, making them ideal for settings where height adjustments are crucial. The key mechanism involves a series of nested cylinders, each sliding within the other, enabling the cylinder to extend to several times its original length when fully deployed.

Their functionality is not just about reaching heights; telescopic cylinders also offer precision and control in operations. In construction, for instance, they facilitate lifting equipment like hydraulic dump beds or concrete pumps. The ability to precisely control the extension and retraction speeds enhances safety and efficiency. Additionally, these cylinders are designed to handle heavy loads, making them suitable for industries such as agriculture, automotive, and material handling, where robust and reliable performance is critical for successful operations. The versatility of telescopic cylinders ensures they remain an integral part of many underbody applications, providing both power and functionality to meet diverse operational needs.

The Ultimate Guide to Understanding Telescopic Cylinders Underbody Applications and Benefits

| Application Area | Functionality | Advantages | Typical Dimensions |

|---|---|---|---|

| Construction Equipment | Provides lifting and lowering capabilities for heavy loads | High lifting capacity and compact design | Stroke Length: 2000 mm, Diameter: 80 mm |

| Agricultural Machinery | Facilitates lifting and tilting of attachments | Enhanced operational efficiency and flexibility | Stroke Length: 1500 mm, Diameter: 100 mm |

| Material Handling | Used for handling and maneuvering loads | Improves safety and reduces labor costs | Stroke Length: 2500 mm, Diameter: 90 mm |

| Automotive Applications | Allows the extension of various automotive parts | Lightweight and compact solution | Stroke Length: 1200 mm, Diameter: 75 mm |

| Waste Management | Aids in the compacting and dumping of waste | Durable and reliable under harsh conditions | Stroke Length: 1800 mm, Diameter: 110 mm |

Key Applications of Telescopic Cylinders in Various Industries

Telescopic cylinders are an essential component in various industries due to their unique ability to provide multiple stages of extension within a compact form factor. This makes them particularly valuable in applications where space is limited but significant lifting force is required. For instance, in construction and material handling, telescopic cylinders enable machinery to perform tasks such as lifting and lowering loads with precision, maximizing efficiency in tight spaces.

The versatility of telescopic cylinders extends beyond just construction; they find applications in transportation, agriculture, and even civil engineering. In transportation, they are often used in truck hoists and specialized equipment, allowing for secure payload handling. In agricultural machinery, these cylinders facilitate the operation of equipment like plows and harvesters, where extending and retracting capabilities are crucial for functionality.

Additionally, the aerodynamics of these cylindrical designs has been studied extensively to improve performance in civil engineering, underscoring their broad relevance across multiple sectors.

Advantages of Underbody Applications for Telescopic Cylinders

Telescopic cylinders have become increasingly popular in various underbody applications due to their compact design and powerful performance. These cylinders, often utilized in construction and heavy machinery, offer significant benefits in terms of space efficiency and operational flexibility. According to a recent report by the Machinery and Equipment Manufacturers Association, the global market for telescopic cylinders is projected to grow by 7.5% annually, driven largely by the rising demand for efficient lifting products in automotive and construction sectors. This growth underscores the effectiveness of underbody applications, where space is often limited yet requires powerful functionality.

One of the key advantages of underbody applications for telescopic cylinders is their ability to provide a greater lifting force through a smaller installation footprint. This is particularly beneficial in vehicles such as dump trucks, where maximizing payload capacity while minimizing vehicle height is crucial. A study published in the Journal of Mechanical Engineering found that telescopic cylinders can perform up to 30% more efficiently compared to traditional hydraulic solutions in similar conditions. Additionally, their multi-stage design allows for extended reach and compact storage, translating to enhanced productivity and versatile performance across various heavy-duty tasks. These factors make telescopic cylinders an essential component for industries looking to improve efficiency and performance in confined spaces.

The Ultimate Guide to Understanding Telescopic Cylinders Underbody Applications and Benefits

Factors to Consider When Choosing Telescopic Cylinders

When selecting telescopic cylinders for underbody applications, several critical factors must be taken into account to ensure optimal performance and longevity. One of the foremost considerations is the design and configuration of the cylinder. According to a report by the International Hydraulics Association, approximately 40% of cylinder failures can be attributed to improper design that does not account for the specific load and operational environment. Therefore, it is vital to evaluate the required stroke length, load capacity, and mounting style to match the demands of the application accurately.

Material selection is another crucial aspect that influences the durability and efficiency of telescopic cylinders. Industries often rely on high-strength, lightweight materials such as aluminum and specialized steels to enhance performance while reducing weight. A recent study by the American Society of Mechanical Engineers highlights that using corrosion-resistant materials can increase the lifespan of hydraulic cylinders by up to 25%, significantly minimizing maintenance costs. Additionally, factors such as sealing systems and lubrication options should be reviewed, as they impact the operational reliability and efficiency of telescopic cylinders under various environmental conditions. Therefore, comprehensive analysis and strategic selection based on these factors are essential for optimizing hydraulics systems in demanding applications.

Maintenance Tips for Optimal Performance of Telescopic Cylinders

Telescopic cylinders play a crucial role in various underbody applications, such as dump trucks and construction machinery, where space constraints must be managed efficiently. To ensure these hydraulic systems operate at their best, regular maintenance is essential. According to a recent report from the International Journal of Engineering Research, poorly maintained hydraulic systems can lead to a performance drop of up to 30%, significantly impacting productivity.

Regular inspection of seals, lubrication of moving parts, and checking for leaks can extend the life of telescopic cylinders and maintain their efficiency. It's recommended to replace seals at least annually or sooner if wear is detected. Furthermore, incorporating a systematic fluid analysis can help identify contaminants that may cause wear or operational failures. A study published by the Hydraulic Institute indicates that implementing such maintenance practices can reduce downtime by approximately 25% and enhance overall efficiency.

Additionally, operators should monitor the operating pressure closely, as excessive pressure can lead to premature failure. Industry data suggests that maintaining the correct operating range can increase the lifespan of a telescopic cylinder by an average of 15-20%. By adhering to these maintenance tips, users can ensure optimal performance and reliability of telescopic cylinders in their applications.

Related Posts

-

Essential Tips for Identifying Reliable Manufacturers of Best Telescopic Cylinders Underbody

-

Top 5 Best Telescopic Cylinders: A Comparative Review for Optimal Performance

-

7 Essential Tips for Choosing the Right Telescopic Cylinder

-

Ultimate Guide to Choosing the Best Hydraulic Oil Cylinder for Your Needs

-

A Comprehensive Guide to Selecting the Best Hydraulic Cylinder for Your Trailer Needs

-

Unmatched Quality in Telescopic Cylinders Shaping Global Manufacturing Excellence from China