Understanding Excavator Hydraulic Cylinders: Essential Maintenance Tips for Optimal Performance

In the world of construction and heavy machinery, the efficiency and reliability of an excavator often hinge on the performance of its hydraulic system. Among the critical components of this system are the Excavator Hydraulic Cylinders, which play a vital role in controlling the movement and operation of the machine. Understanding how these cylinders function, alongside implementing essential maintenance routines, can significantly enhance their longevity and performance. This guide aims to provide you with practical tips and techniques to ensure optimal performance of your Excavator Hydraulic Cylinder, enabling more effective operation in demanding environments. By focusing on maintenance strategies such as regular inspections, proper lubrication, and timely repairs, you can minimize downtime and maximize the productivity of your excavator, ensuring it remains a valuable asset on any job site.

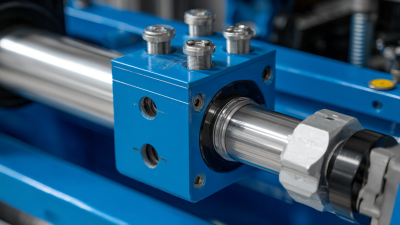

Types of Excavator Hydraulic Cylinders and Their Functions

Excavator hydraulic cylinders are crucial components that enable the machine to perform various tasks, and understanding their types and functions is essential for effective maintenance.

The three primary types of hydraulic cylinders used in excavators are single-acting, double-acting, and telescopic cylinders.

Single-acting cylinders are primarily used for lifting applications, where fluid pressure moves the piston in one direction, while gravity or a spring returns it.

This type of cylinder is efficient for simple tasks but limited in versatility.

On the other hand, double-acting cylinders provide movement in both directions, allowing for more complex operations such as digging and trenching.

Their design facilitates quick and controlled movement by using hydraulic fluid on both sides of the piston.

Telescopic cylinders, which consist of multiple nested cylinders, are designed for compact spaces and are utilized in applications requiring extended reach, such as extending the boom of the excavator.

Each cylinder type plays a unique role in enhancing the functionality of excavators, making it vital to understand their specific applications and maintenance needs to ensure optimal performance.

Common Issues with Hydraulic Cylinders in Excavators

Hydraulic cylinders are crucial components of excavators, enabling precise movement and power. However, they are susceptible to various common issues that can hinder their performance. One major problem is fluid leakage, which not only reduces the efficiency of the cylinder but can also lead to potential damage. Regularly inspecting seals and fitting connections helps identify wear and tear before it escalates.

Another frequent issue is hydraulic system contamination. Dirt, debris, and water can enter the system, leading to corrosion and malfunctions. Implementing a robust filtration system and regularly changing hydraulic fluids can significantly reduce contamination risks.

To ensure optimal performance of hydraulic cylinders, it’s essential to follow some maintenance tips: first, always check for leaks during daily inspections, and address any signs of dripping fluid promptly. Secondly, keep a consistent maintenance schedule, which includes replacing worn seals and filters. Lastly, maintaining proper hydraulic fluid levels and ensuring the system is free from contamination can extend the life and efficiency of cylinders, leading to smooth and effective excavator operations.

Routine Maintenance Practices for Excavator Hydraulic Cylinders

Routine maintenance of hydraulic cylinders in excavators is crucial for ensuring longevity and optimal performance. According to a report by the International Journal of Mechanical Engineering, over 70% of hydraulic system failures can be attributed to inadequate maintenance practices. Regular inspections can help identify issues like leaks or wear before they escalate, saving time and costly repairs in the long run.

**Tip:** Establish a routine inspection schedule that includes checking for hydraulic fluid leaks, ensuring proper cylinder alignment, and assessing seals for wear. Keeping logs of these inspections can help track the condition of each cylinder over time.

Additionally, maintaining clean hydraulic fluid is imperative since contaminated fluid can lead to premature wear of components. A study published in the Journal of Hydraulics found that maintaining fluid cleanliness can extend the service life of hydraulic components by up to 50%. Therefore, regular oil changes and using quality filtration systems are recommended.

**Tip:** Utilize high-quality hydraulic fluids and perform oil analysis periodically to detect contamination levels, which can help optimize the performance of your excavator’s hydraulic system.

Understanding Excavator Hydraulic Cylinders: Essential Maintenance Tips for Optimal Performance

| Maintenance Task | Recommended Frequency | Tools Required | Description |

|---|---|---|---|

| Inspect Hydraulic Fluid Levels | Daily | Dipstick, Fluid | Check hydraulic fluid levels to ensure proper operation and prevent damage. |

| Replace Hydraulic Filters | Every 500 hours | Wrenches, New Filters | Change filters in accordance with the manufacturer's guidelines to avoid contamination. |

| Check for Leaks | Weekly | Visual Inspection | Inspect hoses, fittings, and cylinders for any signs of leakage. |

| Lubricate Moving Parts | Monthly | Lubricant, Grease Gun | Apply lubricant to all moving parts to ensure smooth operation. |

| Test Hydraulic System Pressure | Every 1000 hours | Pressure Gauge | Ensure that the hydraulic system is operating within the recommended pressure range. |

Signs of Wear and Tear in Hydraulic Cylinders

Hydraulic cylinders are vital components of excavators, enabling powerful movements and lifting capabilities. However, with constant usage, these cylinders can exhibit signs of wear and tear that may affect their performance. One of the most common indicators of a failing hydraulic cylinder is leaking fluid. If you notice hydraulic fluid pooling around the cylinder or dripping from seals, it’s a clear sign that the seals may be damaged and need replacement.

Hydraulic cylinders are vital components of excavators, enabling powerful movements and lifting capabilities. However, with constant usage, these cylinders can exhibit signs of wear and tear that may affect their performance. One of the most common indicators of a failing hydraulic cylinder is leaking fluid. If you notice hydraulic fluid pooling around the cylinder or dripping from seals, it’s a clear sign that the seals may be damaged and need replacement.

Another sign to watch for is reduced lifting force or sluggish operation. If your excavator struggles to lift loads that it previously handled effortlessly, this impairment could indicate internal wear or damage within the cylinder. Additionally, unusual noises, such as grinding or knocking sounds during operation, may signal mechanical issues that require immediate attention. Regularly inspecting your hydraulic cylinders for these signs not only prolongs the lifespan of the equipment but also ensures optimal performance and safety in operation.

Best Practices for Troubleshooting Hydraulic Cylinder Problems

Troubleshooting hydraulic cylinder problems in excavators is crucial for maintaining optimal performance and ensuring longevity. One of the first steps in identifying issues is to perform a visual inspection of the hydraulic system. Look for signs of leaks, which can often indicate seal failure or wear in the cylinder. Any visible damage on the hydraulic lines or fittings should also be addressed immediately, as this can lead to significant pressure loss and affect the overall efficiency of the equipment.

Another common issue to troubleshoot is uneven movement, which could signal internal cylinder damage or contamination in the hydraulic fluid. To diagnose this, operators should check the fluid level and quality, as debris or low levels can cause erratic performance. Ensuring all components are clean and well-maintained can prevent further complications. Additionally, regular testing of the hydraulic pressure can help determine if the system is operating within the required parameters, allowing for timely adjustments before major repairs are necessary.

Related Posts

-

Understanding the Functionality of Excavator Hydraulic Cylinders

-

How to Choose the Right Hydraulic Cylinder for Excavator Efficiency and Performance

-

A Comprehensive Guide to Selecting the Best Hydraulic Cylinder for Your Trailer Needs

-

How to Choose the Right Hydraulic Cylinder for Your Forklift Needs Based on Load Capacity

-

Maximizing Efficiency: The Advantages of Upgrading Your Hydraulic Oil Cylinder Systems

-

Unmatched Quality in Telescopic Cylinders Shaping Global Manufacturing Excellence from China