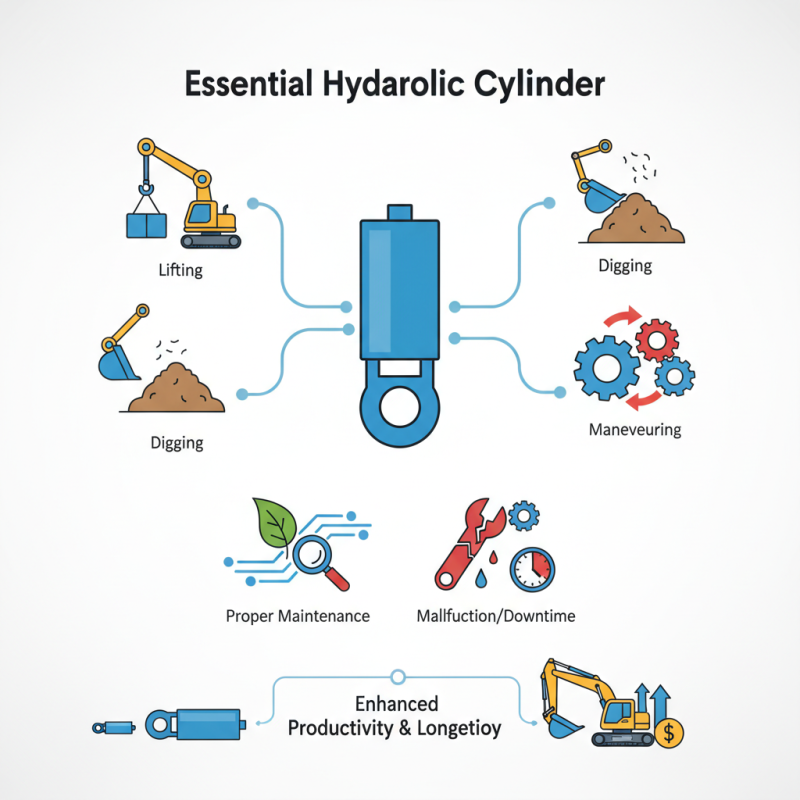

Why is the Excavator Hydraulic Cylinder Essential for Performance?

The Excavator Hydraulic Cylinder plays a critical role in the performance of excavators. This component is responsible for converting hydraulic energy into mechanical energy. Its efficiency directly impacts the machine’s lifting, digging, and maneuvering abilities. A malfunctioning hydraulic cylinder can disrupt operations, leading to costly downtime and repairs.

Improper maintenance may result in reduced efficiency and performance. Regular checks are essential for ensuring proper function. A worn-out cylinder could leak hydraulic fluid, affecting the entire system. This issue highlights the importance of timely inspections and repairs.

Understanding the function of the Excavator Hydraulic Cylinder is vital for operators and technicians. It is not just a mechanical part; it is a lifeline for heavy machinery. Recognizing potential issues early can save money and enhance productivity. Prioritizing this component can lead to better performance and longevity of the excavator.

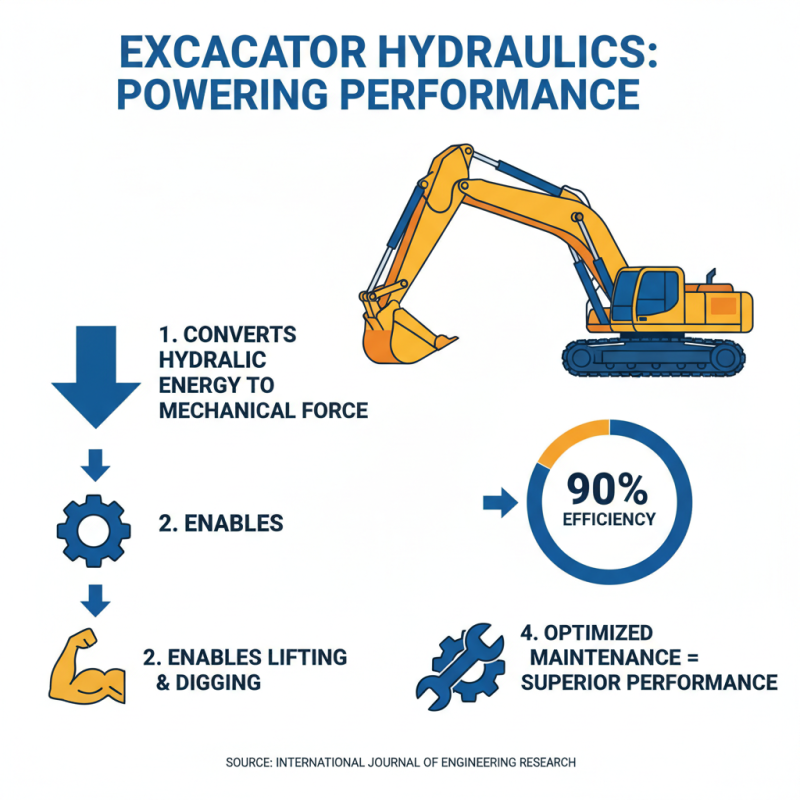

The Role of Hydraulic Cylinders in Excavator Performance Optimization

Hydraulic cylinders are at the heart of excavators, essential for optimizing their performance. These cylinders convert hydraulic energy into mechanical force. This conversion allows excavators to execute powerful lifting and digging motions. According to a report by the International Journal of Engineering Research, hydraulic systems can achieve efficiency levels of over 90%. This impressive statistic illustrates why maintenance and optimization of these cylinders matters.

The characteristics of hydraulic cylinders directly affect how well an excavator performs. For example, cylinder size influences the force outputs. A mismatch can lead to reduced effectiveness. Industry data suggests that a 10% increase in fluid pressure can enhance lifting capacity by 15%. However, such enhancements require careful management to prevent fluid leaks and ensure system integrity. Regular inspection of seals and fittings is vital but often overlooked, leading to potential performance issues.

A well-optimized hydraulic cylinder also contributes to fuel efficiency. Studies indicate that hydraulic systems can save up to 30% in fuel consumption when functioning correctly. Yet, many operators neglect to calibrate these systems. Inadequate calibration can lead to wasted resources and increased operational costs. Observing these small details can yield significant performance improvements and cost savings over time.

Key Components of Excavator Hydraulic Systems and Their Functions

The hydraulic system of an excavator is a key element for its overall performance. At its core, the hydraulic cylinder plays a crucial role. It controls the movement of the arm and the bucket. Without this component, the machine would struggle to lift loads or dig into the ground. A well-functioning hydraulic cylinder applies controlled pressure. This ensures smooth operation and precise movements.

Another significant part is the hydraulic pump. It generates the flow of hydraulic fluid. A strong pump allows the excavator to tackle tough jobs more efficiently.

Pressure relief valves are equally important. They prevent damage by regulating fluid pressure. These components often require regular checks. Neglecting them can lead to performance issues or costly repairs.

Hydraulic hoses are the unseen heroes. They carry hydraulic fluid to various parts. A single leak can disrupt the whole system. It's vital to inspect them frequently. Operators sometimes overlook this simple task.

Small seals and fittings play a critical role too. Their integrity can significantly impact the efficiency of the entire hydraulic system.

Performance Metrics: How Hydraulic Cylinders Influence Excavator Efficiency

Hydraulic cylinders are the heart of excavators. They provide the power needed to lift, dig, and maneuver. Their efficiency directly impacts how an excavator performs on the job site. A precise hydraulic system enables a smoother operation. Poorly maintained cylinders can lead to leaks and slow performance, impacting productivity.

Examining performance metrics reveals the importance of these hydraulic components. Speed and force are two critical aspects. The right hydraulic cylinder can improve cycle times. Increased force means moving more material quickly. If the cylinders are misaligned or worn, efficiency takes a hit. Operators must regularly check for wear and perform maintenance.

In real-world scenarios, the performance of excavators often reveals their latent issues. Inconsistent power delivery can frustrate operators. Small leaks may seem negligible, but they can accumulate over time. Being proactive in maintenance ensures that hydraulic cylinders contribute positively. Understanding these dynamics is key for maximizing efficiency in operations.

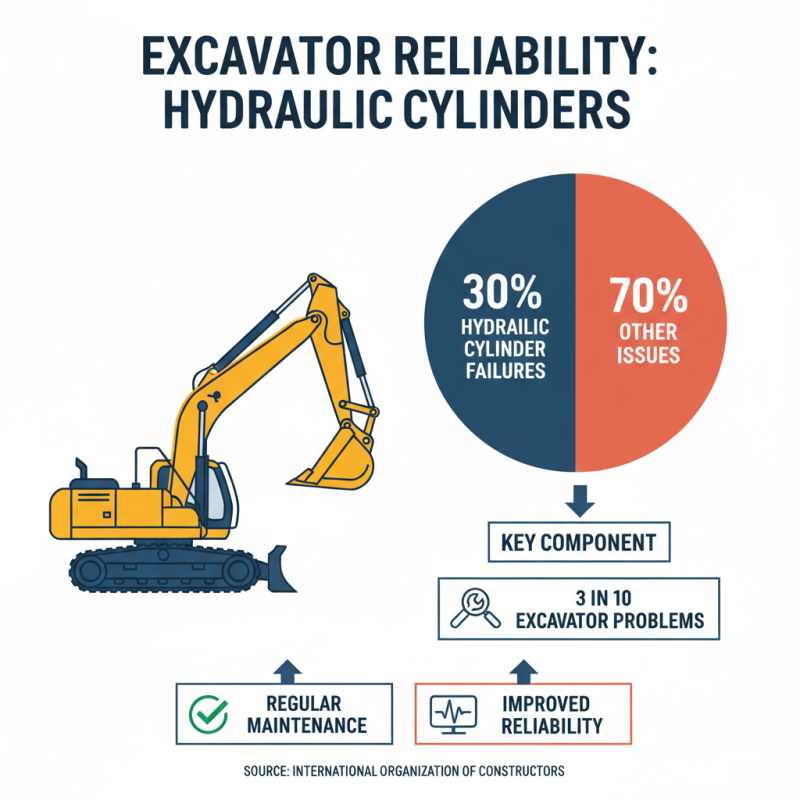

Industry Data on Excavator Hydraulic Cylinder Failure Rates and Maintenance

The hydraulic cylinder is a critical component in excavators. According to the International Organization of Constructors, hydraulic cylinder failures account for 30% of all excavator issues. This high percentage highlights the importance of regular maintenance and monitoring.

Studies show that excavator operators often overlook the hydraulic system. Approximately 25% of operators do not perform routine checks. This negligence can lead to severe breakdowns. Costs associated with repairs can exceed thousands of dollars. Maintaining the hydraulic cylinders could prevent this. A simple inspection can detect wear and tear early on.

Industry data further indicates that proactive maintenance can reduce failure rates by up to 40%. Every hour spent on maintenance saves two hours in repair time. Operators should be aware of the signs of cylinder damage, such as leaks or inconsistent performance. Ignoring these signs often leads to more significant problems. Keeping an eye on the hydraulic system ensures smoother operations and extended equipment life.

Innovations in Hydraulic Cylinder Technology for Enhanced Excavator Productivity

The advancements in hydraulic cylinder technology have revolutionized excavator productivity. Recent studies show that hydraulic cylinders now offer up to 30% more efficiency due to improved design and materials. This innovation is essential for the heavy-duty operations of excavators. Enhanced performance is not just about power. It’s also about precision and reliability in various working conditions.

New materials, such as advanced composites, are being used to reduce weight and increase durability. These materials withstand harsh environments and reduce wear. Industry data indicate that these improvements can lead to a 15% increase in lifespan over traditional cylinders. Despite these advancements, some issues remain. Oil leakage and hydraulic failure continue to be concerns for operators. Regular maintenance is crucial, yet often overlooked.

User feedback indicates that, while innovative technology is appreciated, many operators struggle with complex hydraulic systems. Training is essential, but often neglected. Understanding the mechanics behind these innovative features can make a big difference in overall performance. Despite the impressive efficiency gains, the human factor in operating and maintaining hydraulic systems cannot be underestimated. Balancing innovation with effective training is still a work in progress.

Why is the Excavator Hydraulic Cylinder Essential for Performance? - Innovations in Hydraulic Cylinder Technology for Enhanced Excavator Productivity

| Dimension | Value | Description |

|---|---|---|

| Bore Size | 80 mm | The diameter of the cylinder, critical for lifting capacity. |

| Rod Diameter | 50 mm | The thickness of the piston rod, affecting strength and bending resistance. |

| Stroke Length | 600 mm | The distance the rod moves, determining the range of motion. |

| Operating Pressure | 250 bar | The pressure at which the hydraulic cylinder operates efficiently. |

| Cycle Time | 5 seconds | The time taken for one complete cycle of extension and retraction. |

| Weight | 15 kg | The total weight of the hydraulic cylinder, relevant for machine balance. |

Related Posts

-

How to Choose the Right Excavator Hydraulic Cylinder for Your Needs

-

Ultimate Guide to Choosing the Right Hydraulic Cylinder for Excavators with Key Specs and Tips

-

Ultimate Guide to Understanding Hydraulic Cylinders for Excavators in Global Markets

-

The Ultimate Guide to Choosing the Right Hydraulic Cylinder for Your Excavator Needs

-

Understanding the Role of Excavator Hydraulic Cylinders in Modern Construction Machinery

-

5 Reasons Why Our Best Excavator Hydraulic Cylinder Outperforms Competitors