7 Essential Tips for Choosing the Right Telescopic Cylinder

In the world of hydraulic systems, the selection of the right Telescopic Cylinder plays a critical role in enhancing efficiency and performance across various industries, including construction, manufacturing, and transportation. According to a recent industry report by Markets and Markets, the global hydraulic cylinder market is expected to reach USD 22 billion by 2025, driven by the increasing demand for automation and advanced machinery.

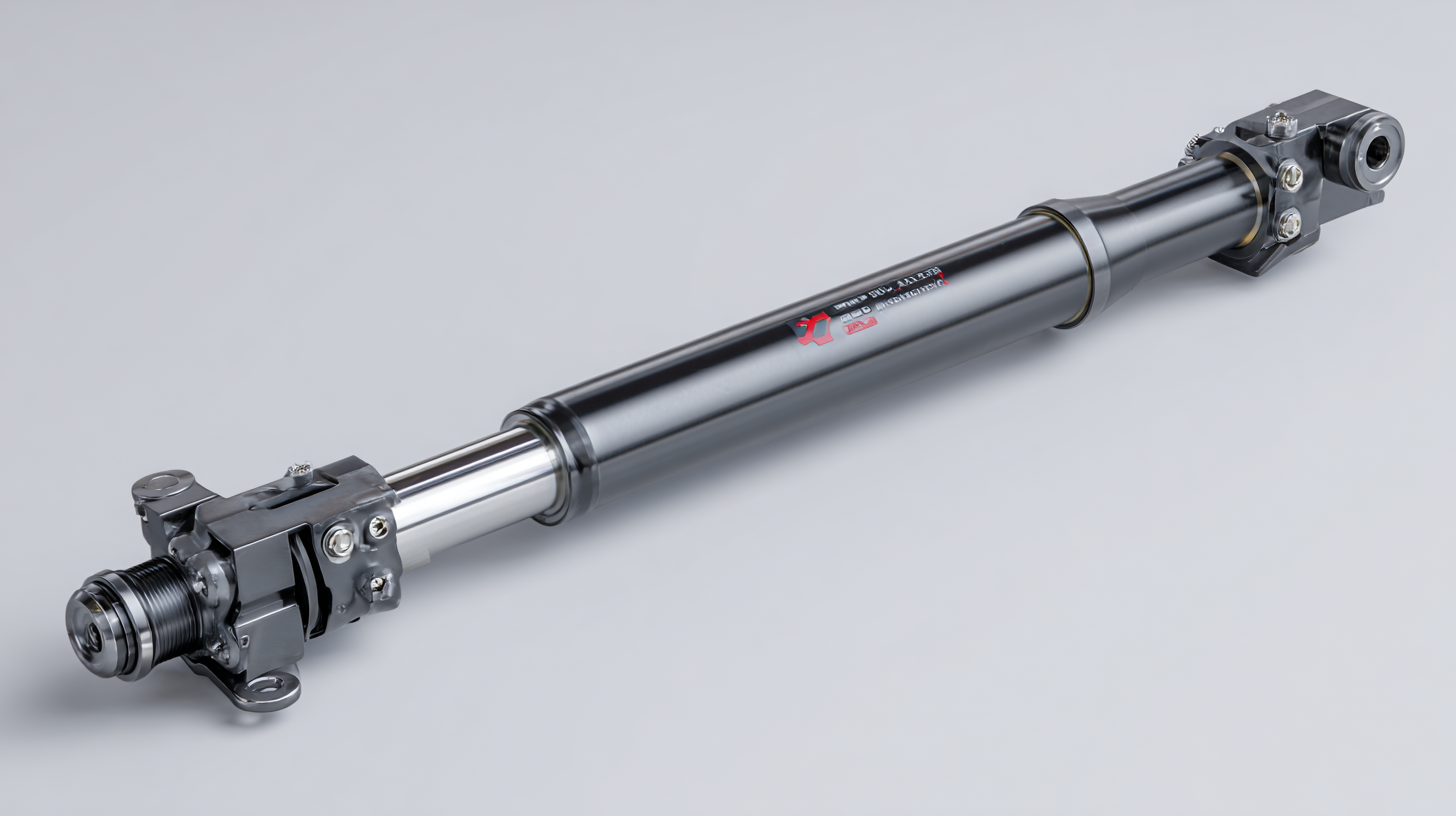

Telescopic Cylinders, known for their compact design and ability to provide high levels of force in a confined space, are particularly valuable in applications such as truck-mounted cranes and mobile equipment. However, choosing the most suitable Telescopic Cylinder can be a daunting task due to the myriad of options available.

Understanding the key factors that influence this choice, including load capacity, stroke length, and material selection, is essential for optimizing performance and ensuring longevity in demanding environments.

Understanding Telescopic Cylinder Types and Their Applications

When selecting the right telescopic cylinder for your application, it’s essential to understand the different types available and their specific uses. Telescopic cylinders are widely utilized in various sectors, including cranes, trucks, and heavy machinery, due to their ability to extend and retract while carrying substantial loads. These multi-stage hydraulic cylinders offer unique advantages by providing a compact design that allows for significant extension, making them ideal for applications that require a long reach but limited space.

Understanding the various applications of telescopic cylinders can further guide your decision. For example, in construction, these cylinders play a pivotal role in lifting and lowering loads efficiently, contributing to safety and effectiveness. Additionally, their versatility allows them to be employed in environments such as factories and logistics, where they handle tasks ranging from material loading to operating complex machinery. By grasping the fundamental types of telescopic cylinders and their applications, you can ensure that you choose a cylinder that meets the specific demands of your operational needs.

7 Essential Tips for Choosing the Right Telescopic Cylinder

Key Factors to Consider When Selecting the Right Telescopic Cylinder

When selecting the right telescopic cylinder for your application, several key factors demand careful consideration. First and foremost is the load capacity. According to a report by the International Fluid Power Society (IFPS), choosing a cylinder with the appropriate load capacity is critical, as exceeding this limit can lead to equipment damage or failure. It’s essential to assess both static and dynamic load requirements, ensuring that the selected cylinder meets the demands of your specific operational environment.

Another vital aspect is the cylinder stroke length, which should align with the operational movement needed in your application. The National Fluid Power Association (NFPA) reports that incorrect stroke length can significantly affect the efficiency of the operating system, leading to increased wear and tear. Additionally, the material of the cylinder plays a critical role in its performance; for instance, selecting corrosion-resistant materials can enhance longevity, particularly in harsh environments. Balancing these factors—load capacity, stroke length, and material—will greatly increase the effectiveness and reliability of your telescopic cylinder.

Comparison of Single-Stage vs. Multi-Stage Telescopic Cylinders

When selecting the appropriate telescopic cylinder, understanding the differences between single-stage and multi-stage options is crucial.  Single-stage cylinders are typically straightforward and efficient for applications requiring minimal stroke length, making them ideal for scenarios with limited vertical lift requirements. These cylinders are known for their simplicity and ease of maintenance, but they may not always provide sufficient reach for heavy lifting tasks.

Single-stage cylinders are typically straightforward and efficient for applications requiring minimal stroke length, making them ideal for scenarios with limited vertical lift requirements. These cylinders are known for their simplicity and ease of maintenance, but they may not always provide sufficient reach for heavy lifting tasks.

On the other hand, multi-stage telescopic cylinders offer greater versatility and extended reach, which is vital in applications such as cranes and construction machinery. A report from the Hydraulic Pneumatics Journal indicates that multi-stage cylinders can achieve up to five times the stroke length compared to their single-stage counterparts. This makes them particularly effective for lifting heavy loads over considerable distances, as seen in factory settings where machinery requires significant vertical movement. Additionally, they are designed to compress into a shorter length, providing more efficient storage and transport solutions.

The choice between single-stage and multi-stage cylinders should be guided by specific application requirements, including load capacity, required stroke length, and available installation space. By carefully considering these factors, users can ensure optimal performance and safety in their operations.

Material Choices for Telescopic Cylinders: Pros and Cons

When selecting a telescopic cylinder, the material choice is critical as it significantly influences performance and durability. Common materials include steel, aluminum, and composite materials, each presenting distinct advantages and disadvantages. According to a report by the International Organization for Standardization (ISO), steel telescopic cylinders are renowned for their strength and resistance to wear, making them ideal for heavy-duty applications. However, they also come with increased weight, which can be a drawback in environments where weight efficiency is paramount.

On the other hand, aluminum cylinders offer a compelling alternative due to their lightweight nature, which can enhance maneuverability and decrease fuel consumption in mobile applications. Industry studies indicate that aluminum can reduce overall component weight by up to 30%, providing significant energy savings in transportation applications. Yet, it’s essential to note that while aluminum resists corrosion better than steel, it may not withstand the same levels of stress and can be more susceptible to dents and impacts. Composite materials are emerging as a versatile option, combining the benefits of both aluminum and steel, but they often come at a higher cost and may have limited availability. Choosing the right material for your telescopic cylinder involves weighing these pros and cons against the specific requirements of your application.

Maintenance Tips for Prolonging the Life of Your Telescopic Cylinder

When it comes to maintaining your telescopic cylinder, regular inspection and care are paramount for ensuring its longevity. Start by routinely checking for any signs of wear or damage, such as scratches or dents on the cylinder’s surface. These imperfections can lead to leaks or decreased performance if not addressed promptly. Additionally, pay attention to the seals and O-rings; any signs of deterioration should be remedied with immediate replacement to prevent fluid loss and ensure optimal operation.

Lubrication is another critical aspect of telescopic cylinder maintenance. Using the appropriate lubricant will reduce friction and wear between moving parts, ensuring smoother operation. It is best to apply lubrication as recommended by the manufacturer and to check levels frequently. Furthermore, always keep the cylinder clean and free from debris, which can cause significant damage over time. A well-maintained telescopic cylinder not only performs better but also contributes to overall safety and efficiency in mechanical operations.