How to Choose the Right Hydraulic Cylinder for Your Trailer?

Choosing the right hydraulic cylinder for your trailer can feel overwhelming. It is vital to understand the specifics of your trailer's needs. A hydraulic cylinder for trailer applications must match the load requirements and operational conditions.

Incorrect selection can lead to inefficient performance or even costly failures. Consider the capacity, stroke length, and mounting style of the hydraulic cylinder. Each detail matters. Neglecting to assess the trailer’s weight distribution or intended use might result in issues down the line.

Research and seek guidance when needed. Don’t rush this decision. The right choice will enhance functionality and safety. Analyze your options thoroughly to avoid potential regrets.

Understanding the Types of Hydraulic Cylinders for Trailers

When selecting a hydraulic cylinder for your trailer, it's vital to understand the different types available. Single-acting cylinders use fluid pressure for extension only. They rely on gravity or a spring for retraction. These are often simpler and more cost-effective. In contrast, double-acting cylinders use fluid on both sides to extend and retract. They provide better control, making them suitable for heavier loads.

Tips: Consider the trailer’s weight capacity. Choose a cylinder that matches or exceeds the required pressure. Misjudging the needed force can lead to failure.

Telescopic cylinders are another option. These have multiple stages, allowing for a compact design when retracted. They are particularly useful for trailers needing significant lift height in tight spaces. However, ensure that the mechanism is suitable for your specific application.

Tips: Pay attention to the mounting style. The wrong mounting can lead to uneven wear. Always think about the environment too, as harsh conditions can affect the cylinder's performance.

Key Factors to Evaluate When Selecting a Hydraulic Cylinder

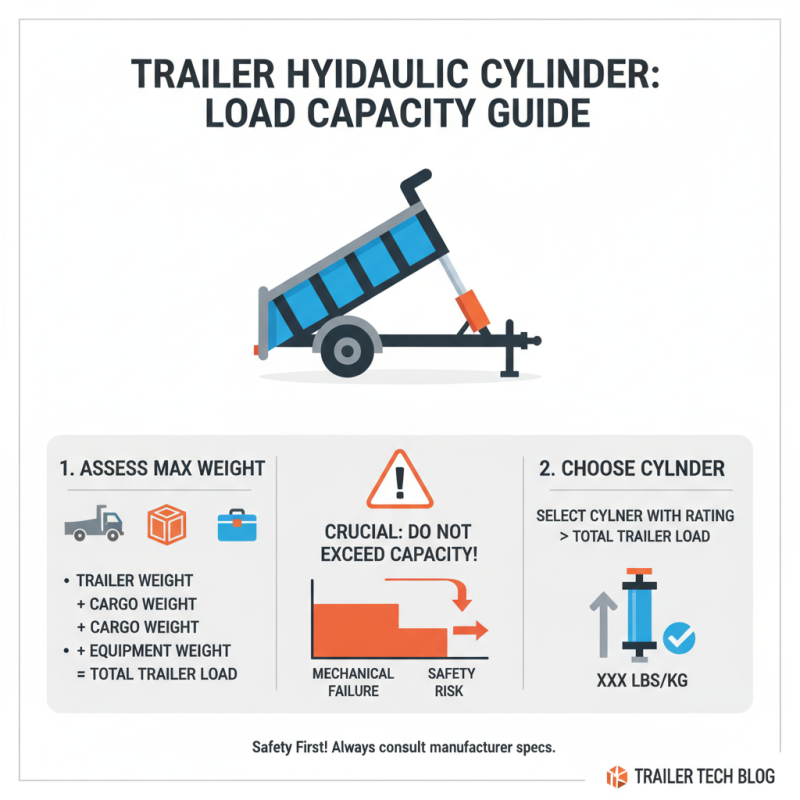

When selecting a hydraulic cylinder for your trailer, several key factors come into play. First, consider the cylinder's load capacity. Calculate the maximum load you expect the cylinder to handle. It's essential to ensure it can handle your specific application. Many users overlook this crucial detail, leading to potential failures.

Another vital factor is the stroke length. Determine how far the cylinder needs to extend and retract. This measurement impacts the performance and efficiency of your trailer. After analyzing stroke length, check the mounting specifications.

Mounting options differ significantly, and poor alignment can cause operational issues.

Finally, think about the environment in which the hydraulic cylinder will operate. Extreme temperatures and exposure to elements can affect performance. Users often forget to account for these aspects, leading to rapid wear and tear. Choosing the right materials for durability can help mitigate these risks. Remember, attention to these details will enhance your trailer's overall functionality and longevity.

Calculating Load Capacity Requirements for Your Trailer

When selecting a hydraulic cylinder for your trailer, understanding load capacity is crucial. Start by assessing the maximum weight your trailer is designed to carry. This includes the combined weight of the trailer, cargo, and any additional equipment. Keep in mind that exceeding this capacity can lead to mechanical failure, posing risks to safety.

Tips: Always factor in a safety margin. A 20% buffer above the estimated load is advisable. This accounts for unexpected weights and uneven load distribution.

Next, consider the type of hydraulic cylinder that suits your needs. Single-acting cylinders are simpler but limited. Double-acting cylinders offer more versatility, allowing for better control and lifting power. Their complexity may require more maintenance, which could be a concern.

It’s also essential to think about the mounting points. Ensure they are strong enough to support the weight and stress during operation. Sometimes, this is overlooked, leading to inadequate support and potential failures.

Tips: Regularly inspect your system for wear and tear. Small issues can grow into significant problems. Always be aware of how your cylinder performs under different loads.

Importance of Cylinder Stroke Length in Hydraulic Applications

Choosing the right hydraulic cylinder for your trailer is a crucial step. One of the most significant factors is the cylinder stroke length. This length determines how far the cylinder can extend and retract. A proper stroke length ensures your trailer operates efficiently and safely.

When considering stroke length, think about your specific needs. Are you lifting heavy loads frequently? A longer stroke may be necessary. However, longer cylinders can be bulkier. This might complicate your trailer's design. You might also have space constraints to consider.

Here are some tips: Measure the height of your trailer when loaded. Ensure the cylinder can handle that height comfortably. Also, consider future needs. If you plan to expand your operations, a slightly longer stroke could save you from additional costs later.

Another tip is to think about the weight of the loads you carry. A heavier load might require a different cylinder strength and stroke length. Reflect on past experiences. Did your previous cylinder struggle? Take notes and apply those lessons. Addressing stroke length is key, but it can often be an overlooked detail.

Material Choices: Enhancing Durability and Performance in Cylinders

When selecting hydraulic cylinders for trailers, material choice is crucial. Different materials offer varying strengths and durability levels. For example, steel cylinders provide excellent resistance to wear and high pressure but can be heavy, impacting the trailer's overall efficiency. According to industry reports, trailers equipped with lightweight aluminum cylinders can improve fuel efficiency by up to 15%. Aluminum is more resistant to corrosion, making it ideal for environments exposed to moisture or chemicals.

Another option is composite materials, which are gaining traction due to their balance of strength and weight. These materials can outperform traditional metal cylinders in certain conditions, especially in off-road applications. However, they may not be suitable for all types of loads. A study indicated that 30% of users experienced issues with wear over time when using composites for heavy-duty applications. This highlights the importance of matching material characteristics with specific use cases.

While selecting the right material can enhance performance, it is equally important to consider maintenance needs. For instance, galvanized steel provides corrosion resistance but requires regular inspections to ensure integrity. Ignoring these aspects can lead to failures. So, revisiting material choices and their implications is essential for making informed decisions.

Related Posts

-

Understanding the Best Hydraulic Oil Cylinder Types for Your Needs

-

Top Strategies for Enhancing Performance of Hydraulic Oil Cylinders

-

Hydraulic Cylinder For Trailer Common Issues Impacting Performance and Longevity

-

7 Solid Reasons to Choose Hydraulic Oil Cylinders for Your Industrial Needs

-

Ultimate Guide to Understanding Hydraulic Cylinders for Excavators in Global Markets

-

How to Choose the Best Hydraulic Cylinder for Your Trailer Needs