How to Choose the Right Dump Truck Hydraulic Hoist for Your Needs?

Choosing the right Dump Truck Hydraulic Hoist can be challenging. With various options on the market, understanding your needs is crucial. This decision impacts efficiency, safety, and productivity.

When selecting a hoist, consider the load capacity. It should match your truck’s specifications. Think about the type of materials you transport, too. A hoist designed for heavier loads may not be necessary for lighter materials. Also, consider the hoist’s hydraulic system. The performance varies widely among different models.

Moreover, maintenance requirements are often overlooked. Skipping regular upkeep can lead to costly repairs. Reflect on how often you will use the hoist. A high-usage scenario demands a robust system. Remember, a well-chosen Dump Truck Hydraulic Hoist can enhance your operations, but it must fit your specific needs.

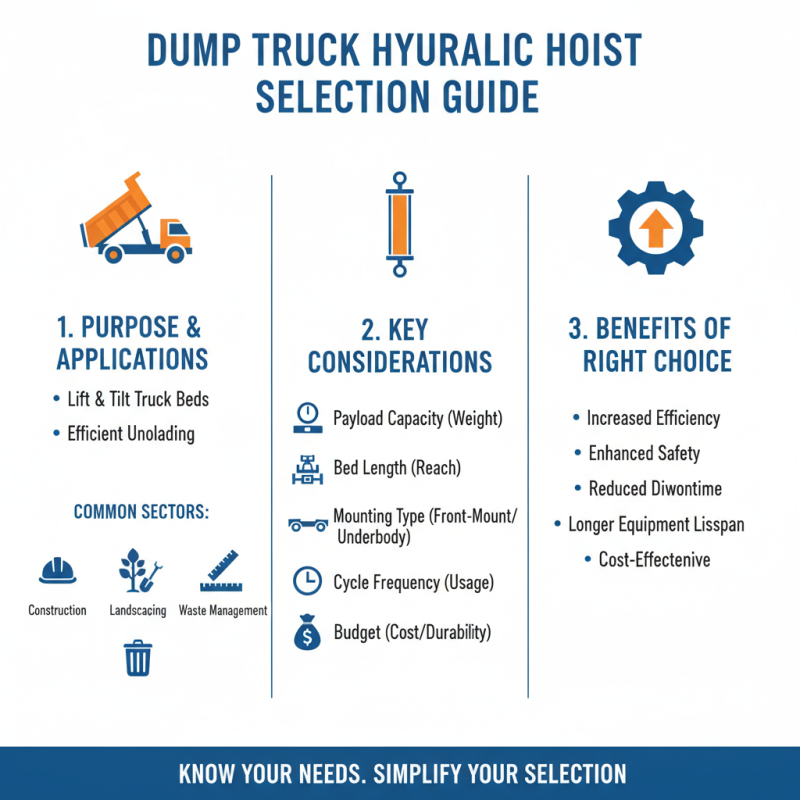

Understanding the Purpose and Applications of Dump Truck Hydraulic Hoists

When choosing a dump truck hydraulic hoist, it's essential to understand its purpose and applications. These hoists are primarily used to lift and tilt truck beds for efficient unloading. They are common in construction, landscaping, and waste management sectors. Knowing your specific needs will simplify your selection process.

Consider the weight capacity. Not all hoists can handle the same load. A bigger hoist is not always better. Match the hoist capability to your truck and the materials you transport. This will enhance performance and ensure safety. Make sure your choice is suitable for your expected workload.

Tips: Regular maintenance can prolong the life of your hoist. Inspect hydraulic lines and connections frequently. Keep an eye out for any signs of wear or leaks. Additionally, familiarize yourself with the controls. Understanding how to operate the hoist safely prevents accidents. Investing time in learning will save you troubles down the road.

Key Specifications to Consider When Choosing a Hydraulic Hoist

When selecting a dump truck hydraulic hoist, understanding key specifications is crucial. Load capacity is one major factor. According to industry reports, a common range is between 5,000 to 20,000 pounds. Choose a hoist that meets your maximum load requirements. If you're frequently transporting heavier loads, opt for a model with a higher capacity.

Another important specification is the hoist's cycle time. This refers to how quickly it raises and lowers the load. Typical cycle times range around 15 to 25 seconds. A faster cycle time can improve efficiency on job sites. However, faster isn't always better. Consider the trade-off between speed and stability. A more stable situation could mitigate risk.

Additionally, look at the lifting angle of the hoist. Most hoists operate between 40 to 50 degrees. This angle influences how easy it is to unload materials. You might find certain angles are not ideal for all materials. Some operators might prefer a more extended angle for heavier loads, ensuring a smooth discharge. Always reflect on your unique operational needs. Choose wisely, as the wrong specifications can lead to operational inefficiencies.

Evaluating Load Capacity and Lift Height Requirements

When selecting a dump truck hydraulic hoist, understanding load capacity and lift height is essential. Different tasks require different capabilities. If you’re hauling heavy materials, ensure the hoist can handle the maximum weight. Overloading can lead to equipment failure or accidents.

Lift height is equally critical. Some projects need only a modest height, while others require significant elevation for optimal unloading. Evaluate the specifications of your project site. Are there overhead restrictions? Consider how quickly you need to unload materials.

Balancing these needs can be challenging. You may find a hoist that meets weight limits but falls short on lift height. Sometimes, a compromise is necessary. Make sure to review the hoist’s performance under different conditions. It’s wise to consult with operators who have practical experience. Their insights can guide your decision, ensuring you choose the right hoist for your tasks.

How to Choose the Right Dump Truck Hydraulic Hoist for Your Needs?

| Hoist Model | Load Capacity (lbs) | Lift Height (ft) | Weight (lbs) | Hydraulic Type |

|---|---|---|---|---|

| Model A | 12,000 | 7 | 1,200 | Single Acting |

| Model B | 14,000 | 8 | 1,350 | Double Acting |

| Model C | 10,000 | 6 | 1,000 | Single Acting |

| Model D | 16,000 | 9 | 1,500 | Double Acting |

| Model E | 18,000 | 10 | 1,800 | Single Acting |

Comparing Hydraulic Systems: Single-Acting vs. Double-Acting Hoists

When selecting a hydraulic hoist for your dump truck, understanding the difference between single-acting and double-acting systems is crucial.

Single-acting hoists utilize hydraulic pressure to lift the load and rely on gravity to lower it. This can work fine for lighter loads or simple tasks. However, it may lack control during descent.

Double-acting hoists, on the other hand, provide hydraulic pressure for both lifting and lowering. This allows for better control over the load, making it a preferred choice for heavy-duty applications. For instance, if you frequently handle construction materials, a double-acting system could improve precision and safety.

Tips: Consider your typical load and frequency of use. If you rarely lift heavy items, a single-acting hoist might suffice. On the contrary, investing in a double-acting hoist can save hassles down the line.

Analyze your work environment. If conditions are rugged or unpredictable, the control of a double-acting system might be essential to avoid accidents.

Choose wisely. An informed decision can ensure efficiency in your operations.

Maintenance and Durability Factors for Long-Term Performance

When choosing a dump truck hydraulic hoist, maintenance and durability are critical factors. According to a recent industry report, regular maintenance can extend the life of hydraulic systems by up to 30%. This makes careful selection even more important. Look for hoists that use high-quality materials and offer easy access for repairs. Components made from durable alloys or coated to resist corrosion can significantly enhance longevity.

Issues often arise due to improper maintenance. For example, neglecting to check fluid levels can lead to system failures. In fact, the same report indicates that 40% of hydraulic failures stem from fluid contamination. Maintaining clean fluids is essential. Implementing a routine inspection schedule is one practical way to ensure your hoist performs well over time.

Durability should not be overlooked. A robust hydraulic hoist can withstand demanding work conditions. The best options often have load ratings that exceed expected usage. This safety margin helps prevent breakdowns. But remember, no mechanism is immune to wear. Be prepared to address and analyze any performance drop. Regularly evaluating your equipment can help identify issues before they become major problems. Neglect can lead to costly downtime and repairs.

Hydraulic Hoist Capacity vs. Maintenance Frequency

Related Posts

-

7 Best Practices for Using Dump Truck Hydraulic Hoist Effectively

-

Why Choosing a Dump Truck Hydraulic Hoist Is Essential for Efficient Construction Operations

-

The Ultimate Guide to Dump Truck Hydraulic Hoist Innovations in 2025

-

5 Reasons Why Our Best Excavator Hydraulic Cylinder Outperforms Competitors

-

Ultimate Checklist for Choosing the Right Hydraulic Cylinder for Your Forklift

-

What is a Hydraulic Cylinder For Trailer and How Does It Work