How to Choose Telescopic Cylinders for Underbody Applications?

Choosing the right telescopic cylinders for underbody applications can be challenging. These components play a crucial role in various machinery and vehicles. Their design and functionality greatly influence overall performance.

When selecting telescopic cylinders underbody, consider specific requirements. Factors like load capacity, stroke length, and installation space are crucial. Each application has unique needs that require careful attention. Some choices may not align with expectations.

Efficiency is vital, but overlooking quality can lead to issues. Poor selection can result in failures or inefficiencies. It's essential to evaluate not only the specifications but also the manufacturer’s reputation. Seeking advice or conducting further research may lead to better choices. Remember, the goal is to balance performance and longevity.

Key Factors to Consider When Selecting Telescopic Cylinders

When selecting telescopic cylinders for underbody applications, several key factors play a significant role. The load capacity is crucial. Ensure the cylinder can handle the maximum anticipated load without risk of failure. Additionally, stroke length should match the requirements of the application. A mismatch can lead to performance issues or even damage.

Another important consideration is the environment. Is the application exposed to harsh conditions? If so, corrosion resistance is vital. Choose materials designed to withstand such environments. Environmental factors like temperature can also affect performance, so it’s essential to consider the operating conditions.

Also, pay attention to the mounting configuration. A poorly aligned mounting can impact efficiency. Consider the ease of installation and maintenance as well. Some designs may seem easier at first but could become problematic down the line. Reflect on these aspects to ensure you choose the right telescopic cylinder for your specific underbody application.

Understanding Different Types of Telescopic Cylinders for Underbody Use

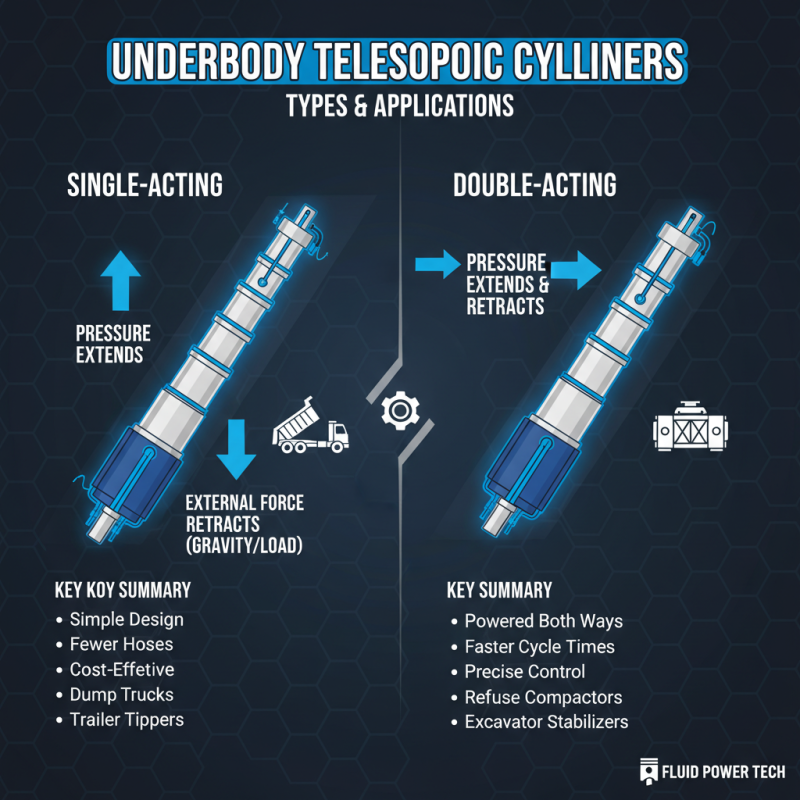

When selecting telescopic cylinders for underbody applications, it’s crucial to understand the various types available. Each type serves a specific purpose. For example, single-acting cylinders extend under pressure but rely on external forces to retract. This simplicity can be an asset, but it may lack the efficiency needed for some operations.

In contrast, double-acting cylinders offer power in both directions. They provide greater control and are often preferred for heavy loads. However, the complexity comes at a higher cost. Additionally, guiding mechanisms play a significant role. They help maintain alignment, but if not properly designed, they might lead to wear and require regular maintenance.

Consider the environment in which these cylinders will operate. Factors like temperature, humidity, and the presence of contaminants can affect performance. Selecting a cylinder that is well-suited to these conditions is vital. Ultimately, careful evaluation of the operational demands and the specific type of telescopic cylinder is necessary. This thoughtful approach can prevent costly mistakes down the line.

Evaluating Load Capacity and Performance Requirements

When evaluating load capacity for telescopic cylinders in underbody applications, several factors come into play. Load capacity depends largely on the cylinder’s design and material strength. According to a recent industry report, the optimal load capacity for standard applications often ranges between 10,000 to 25,000 pounds. It’s crucial to assess the specific requirements of your machinery.

Performance requirements also need attention. The cycle time of a telescopic cylinder often impacts operational efficiency. Industry data shows that reducing cycle times by just 10% can lead to a significant increase in overall productivity. However, engineers sometimes overlook how temperature fluctuations can influence cylinder performance. High or low temperatures can affect hydraulic fluid viscosity, complicating the functionality.

Moreover, it’s essential to consider mounting options and geometry. Inadequate design may lead to improper loading and premature failure. A study highlighted that 15% of system failures stem from poor alignment or mounting issues. This data must be addressed when selecting a cylinder to ensure long-term reliability under challenging conditions.

Load Capacity of Telescopic Cylinders for Underbody Applications

Maintenance and Durability Considerations for Telescopic Cylinders

When it comes to telescopic cylinders for underbody applications, maintenance and durability are paramount. These cylinders operate in challenging environments. They face dirt, moisture, and heavy loads. Regular inspections can prevent unexpected failures. A simple visual check can often reveal signs of wear. Ensure that seals are intact. Worn seals compromise efficiency and can lead to significant downtime.

Selecting the right materials for durability is crucial. Opt for corrosion-resistant finishes. This choice can extend the lifespan of the cylinder. However, one must also consider the environment. Different situations may require different materials. It’s not just about the initial choice; examine the long-term performance as well. A cylinder may look good today but might not handle future wear as expected.

Incorporating a routine maintenance schedule can make a difference. Change oils regularly, and clean the cylinder thoroughly. Paying attention to minor details can prevent major issues. Neglecting these aspects can lead to expensive repairs. This is a common oversight. Many tend to prioritize performance over upkeep. Balancing both is essential for achieving the best outcomes in underbody applications.

Cost-Effectiveness and Supplier Selection Tips for Telescopic Cylinders

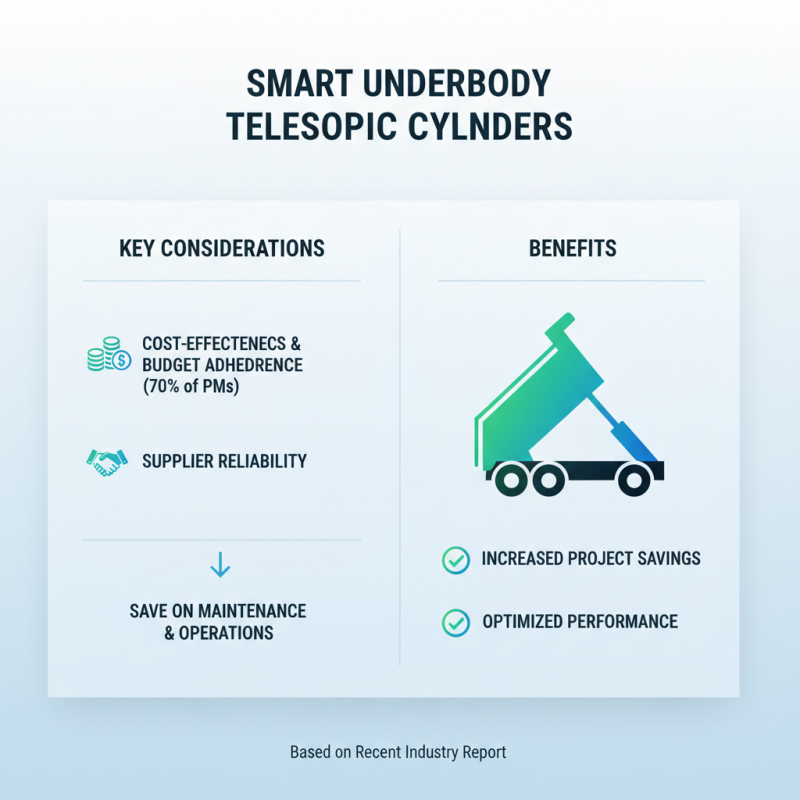

Selecting the right telescopic cylinders for underbody applications requires careful consideration of cost-effectiveness and supplier reliability. In a recent industry report, nearly 70% of project managers emphasized the importance of budget adherence. A well-chosen cylinder can lead to significant savings, especially when factoring in maintenance and operations.

Cost-effectiveness is not solely about the initial price. Long-term operational efficiency matters. For instance, cylinders with lower friction coefficients can extend lifespan and reduce energy consumption. Suppliers can provide detailed specifications. Look for those who offer comprehensive service packages. In a study, 65% of companies regretted not verifying supplier reliability before purchasing. This highlights the need for thorough research.

Supplier selection should also focus on warranty and support. A robust warranty can save unexpected costs in the future. Surveys show that prompt technical support is crucial for over 60% of efficient operations. Choosing a supplier without assessing their track record can lead to regrets. Balancing cost with quality is essential. Aim for a partner who values long-term collaborations. This may lead to better pricing as volumes increase. Reflect on what works best for your specific application needs.

Related Posts

-

Ultimate Guide to Mastering Telescopic Cylinders Underbody for Enhanced Performance

-

The Ultimate Guide to Sourcing Telescopic Cylinders Underbody for Global Buyers

-

Exploring Alternative Solutions for Telescopic Cylinders Underbody Applications

-

The Ultimate Guide to Understanding Telescopic Cylinders Underbody Applications and Benefits

-

How to Choose the Right Telescopic Cylinders Underbody for Optimal Performance

-

2025 Top Insights on Telescopic Cylinders Underbody Technology and Applications