How to Choose the Right Telescopic Cylinders Underbody for Optimal Performance

In the realm of heavy machinery and transportation equipment, the significance of selecting the right Telescopic Cylinders Underbody cannot be overstated. According to a recent report by ResearchAndMarkets, the global market for hydraulic cylinders is projected to reach $14.2 billion by 2027, indicating a robust growth trajectory driven by increasing demand for efficient lifting and hoisting solutions across various industries. The performance and reliability of telescopic cylinders are critical factors that influence operational efficiency and safety, especially in applications like dump trucks, aerial lifts, and construction machinery. By understanding the intricacies of these components, businesses can optimize their performance, thereby ensuring maximum productivity and minimizing maintenance costs. This blog will explore the essential criteria for choosing the right telescopic cylinders, offering insights into maximizing operational effectiveness.

Understanding the Different Types of Telescopic Cylinders and Their Applications

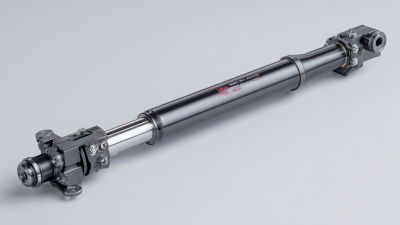

When selecting the right telescopic cylinders for underbody applications, it is crucial to understand the various types available and their specific applications. Telescopic cylinders are specialized hydraulic devices that can extend and retract to perform tasks, making them essential for the operations of trucks and trailers. Unlike structural supports, these cylinders are specifically designed to manage the lifting and dumping of loads, allowing for efficient material handling in construction and waste management sectors.

Different types of telescopic cylinders exist, each tailored for various functionalities. Single-acting cylinders rely on hydraulic pressure for extension, while double-acting cylinders can control both extending and retracting movements. Additionally, the length and number of stages in the cylinder can affect its performance in terms of load capacity and extension height. Understanding these specifications not only aids in choosing the right cylinder but also enhances the overall efficiency of hydraulic systems, which are projected to see significant growth in the next decade, from an estimated USD 14.3 billion in 2021 to USD 27.5 billion by 2035. The right choice will ultimately lead to improved operational performance and longevity of equipment in demanding environments.

Key Factors Influencing the Performance of Telescopic Cylinders in Heavy Machinery

When selecting telescopic cylinders for heavy machinery, understanding the key factors that influence their performance is crucial. The hydraulic fluid power cylinder market is projected to witness significant growth, with an expected increase from USD 1.5 billion in 2024 to USD 2.8 billion by 2033. This highlights the increasing demand for reliable hydraulic systems in various applications, particularly within construction equipment.

When selecting telescopic cylinders for heavy machinery, understanding the key factors that influence their performance is crucial. The hydraulic fluid power cylinder market is projected to witness significant growth, with an expected increase from USD 1.5 billion in 2024 to USD 2.8 billion by 2033. This highlights the increasing demand for reliable hydraulic systems in various applications, particularly within construction equipment.

One of the primary factors affecting the performance of telescopic cylinders is the choice of hydraulic fluid. Different types of hydraulic fluids can impact efficiency, responsiveness, and wear on cylinder components. Additionally, the material selection for the hydraulic actuators, including cylinders, caps, and pistons, plays a vital role in longevity and reliability. Opting for materials that resist corrosion and fatigue can drastically improve the service life of the cylinders under heavy operational conditions.

Tips: When choosing a telescopic cylinder, always consider the specific application requirements, including load capacity and operating environment. Regular maintenance and potential repairs can extend the lifespan of your hydraulic systems. Monitoring the condition of hydraulic fluids can prevent performance issues and enhance efficiency over time.

Comparative Analysis of Material Choices for Optimal Durability and Efficiency

When selecting telescopic cylinders for optimal performance, understanding material choices is crucial. A 2021 industry report by the National Fluid Power Association (NFPA) highlighted that steel remains the preferred material due to its superior tensile strength and fatigue resistance. Despite being heavier, the high yield strength of steel allows for the construction of cylinders capable of withstanding extreme loads and harsh conditions, making it an excellent choice for applications in construction and heavy machinery.

Conversely, advancements in materials technology have made aluminum an increasingly popular option for specific applications. A study published in the Journal of Materials Science found that aluminum cylinders exhibited a weight reduction of up to 50% compared to their steel counterparts while maintaining adequate performance under moderate loads. This weight advantage can lead to improved fuel efficiency in mobile applications, underlining the need for a careful analysis of operational requirements. Additionally, newer composite materials are emerging, boasting enhanced corrosion resistance, which is vital in environments exposed to moisture and chemicals.

Understanding these material properties is essential to choosing the right telescopic cylinders, ensuring they meet the demands of both durability and efficiency in their intended applications.

Evaluating Hydraulic Specifications for Enhanced Telescopic Cylinder Functionality

When selecting the right telescopic cylinders for optimal performance, it's crucial to evaluate the hydraulic specifications that dictate their functionality. The global hydraulic cylinder market, valued at USD 14.3 billion in 2021, is projected to grow to USD 18.3 billion by 2027, underscoring the increasing demand for efficient and reliable hydraulic systems. Key specifications to consider include the maximum operating pressure, stroke length, and load capacity, which all play a vital role in ensuring that the cylinders meet the operational requirements of your equipment.

Another essential aspect is the selection of materials and seal types. The right combination can prevent leakage and increase the durability of the cylinders, which is particularly important in demanding environments. Additionally, understanding the application and environment in which the telescopic cylinders will operate can guide you in selecting the appropriate features, such as corrosion resistance for outdoor use or enhanced adaptability for fluctuating weight loads. By meticulously evaluating these hydraulic specifications, operators can enhance the efficiency and functionality of their telescopic cylinders, contributing to overall performance improvement in various applications.

Maintenance Tips for Prolonging the Life of Telescopic Cylinder Underbodies

When it comes to maintaining the longevity of telescopic cylinder underbodies, regular upkeep is essential. Just as car owners are looking for ways to extend the life of their vehicles, implementing effective maintenance practices for your equipment can significantly enhance performance. One fundamental tip is to ensure proper lubrication. Regularly checking and treating the moving parts with appropriate lubricants minimizes friction and wear, which in turn prolongs the life of the cylinders.

Another important aspect is to keep the underbodies clean and free from debris. Just as machinery benefits from routine cleaning, telescopic cylinders also perform better when they are not compromised by dirt or contaminants. This can prevent rust and corrosion, which are significant factors in reducing the lifespan of equipment. Lastly, monitoring operating temperatures is crucial. High temperatures can lead to material fatigue; thus, ensuring adequate cooling and ventilation can help avoid overheating and maintain optimal performance.

Related Posts

-

The Ultimate Guide to Understanding Telescopic Cylinders Underbody Applications and Benefits

-

The Ultimate Guide to Sourcing Telescopic Cylinders Underbody for Global Buyers

-

Ultimate Guide to Mastering Telescopic Cylinders Underbody for Enhanced Performance

-

Essential Tips for Identifying Reliable Manufacturers of Best Telescopic Cylinders Underbody

-

7 Essential Tips for Choosing the Right Telescopic Cylinder

-

Unmatched Quality in Telescopic Cylinders Shaping Global Manufacturing Excellence from China