How to Choose the Right Hydraulic Cylinder for Your Forklift Needs Based on Load Capacity

Choosing the right hydraulic cylinder for your forklift needs is crucial for ensuring operational efficiency and safety in material handling. According to the Industrial Truck Association, the forklift market is projected to grow significantly, with an expected annual increase of around 5% over the next five years. As forklifts are integral to various industries, the demand for dependable hydraulic components, particularly hydraulic cylinders for forklifts, is paramount. These cylinders not only affect lifting capacity but also play a vital role in the overall performance and longevity of the equipment. A properly selected hydraulic cylinder can enhance load capacity, increase productivity, and reduce maintenance costs. Therefore, understanding the specifications and load requirements is essential for making an informed decision that aligns with the operational demands of your business.

Factors to Consider When Selecting Hydraulic Cylinder Load Capacity for Forklifts

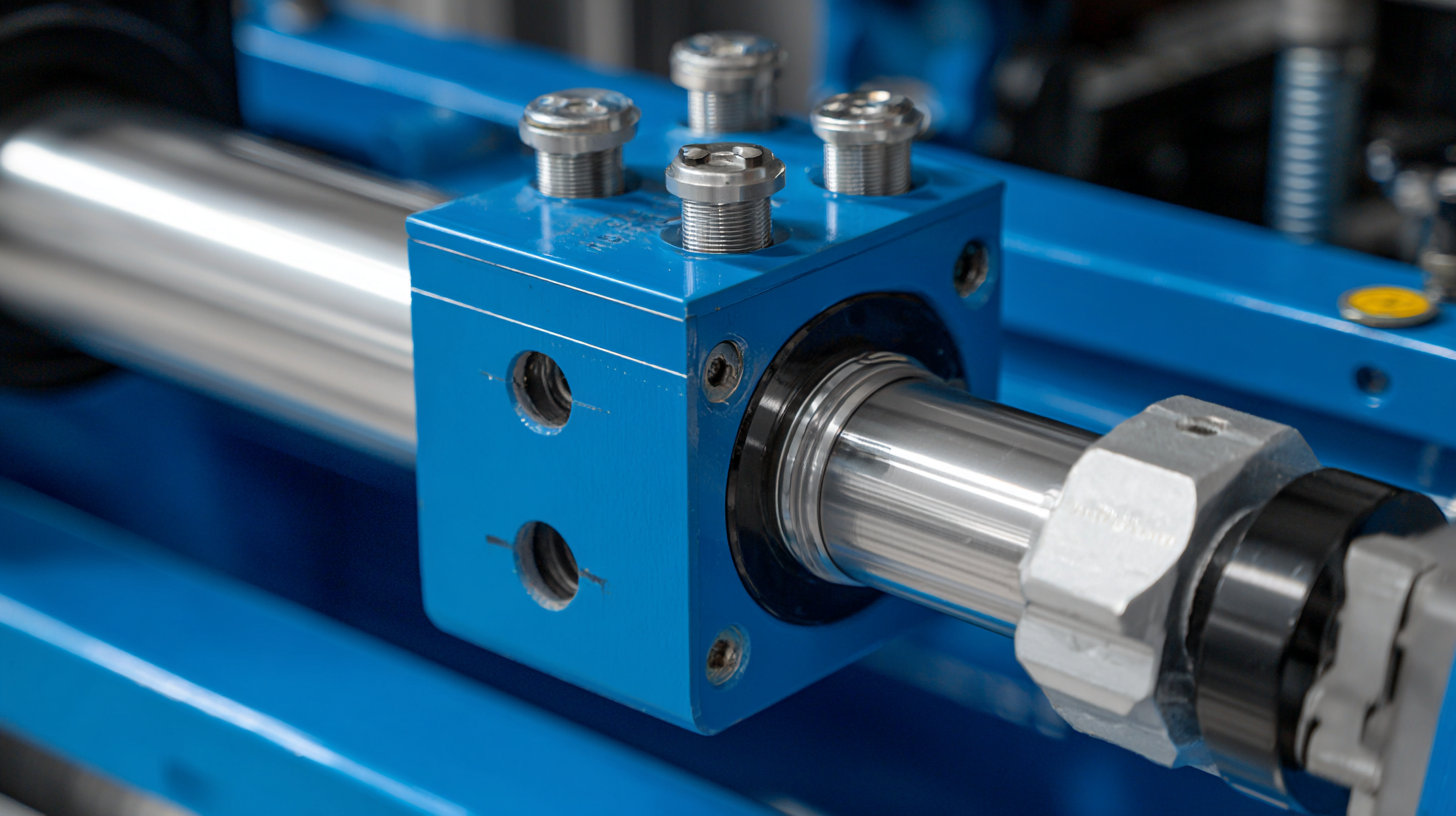

When selecting the appropriate hydraulic cylinder for your forklift, one of the primary considerations is the load capacity it needs to support. The hydraulic cylinder must be able to handle the maximum weight you expect to lift without faltering. This involves not only assessing the weight of the loads but also considering dynamic factors, such as the height at which the load will be lifted and the frequency of operation. Overloading a cylinder can lead to critical failures, so it's vital to choose one rated higher than your maximum load requirements.

Additionally, the operating environment plays a significant role in determining the right hydraulic cylinder for your needs. Factors such as temperature, exposure to corrosive substances, and the presence of dirt or debris can impact the performance of the cylinder. Choose materials and seals that can withstand your specific conditions to ensure longevity and reliability. Finally, consider the cylinder's bore size and stroke length, as these measurements can significantly affect lifting efficiency and speed, ensuring that your forklift operates optimally while safely handling loads.

Understanding Forklift Specifications: Matching Hydraulic Cylinder to Vehicle Requirements

When selecting a hydraulic cylinder for a forklift, it is essential to understand the specific requirements based on the forklift's specifications. Forklifts typically come in various models with distinct load capacities, which can range from 1,500 to over 10,000 pounds. According to a report from the Industrial Truck Association, the majority of industrial forklifts operate within a load capacity between 3,000 and 5,000 pounds. This capacity directly impacts the design and specifications of the hydraulic cylinder, which must be able to lift and lower loads efficiently while ensuring safety.

The matching of hydraulic cylinder specifications to forklift requirements involves considering factors such as bore size, stroke length, and pressure ratings. For instance, a standard lift cylinder operates at pressures between 1,500 and 3,000 psi. According to market research from Transparency Market Research, improper matching can lead to failures, resulting in safety hazards and increased maintenance costs. Therefore, understanding the hydraulic specifications of the forklift—details like the required force output and the operational environment—enables operators to select the ideal hydraulic cylinder that not only meets load demands but ensures optimal performance and longevity.

The Importance of Application Type in Hydraulic Cylinder Selection for Forklift Operations

Choosing the right hydraulic cylinder for your forklift requires careful consideration of the application type, as it directly affects performance and efficiency. According to a report by the Industrial Truck Association (ITA), approximately 75% of forklift accidents are a result of improper equipment use, often linked to inadequate selection of hydraulic components. Understanding the specific demands of your operations—such as whether you're lifting heavy shipping containers or moving lighter packages—will guide you in selecting the appropriate hydraulic cylinder that can handle specific load capacities while maximizing safety.

Moreover, the application type influences the dimensions and design of the hydraulic cylinder. For instance, applications that involve frequent lifting and lowering cycles, such as those seen in warehouse environments, will require cylinders designed for high cycle frequency. A recent survey from the Forklift Manufacturers Association highlights that cylinders with a bore size optimized for quick response times can enhance operational efficiency by as much as 20%. Overall, prioritizing application type during the selection process can significantly improve the reliability and performance of your forklift operations, minimizing the risk of mechanical failures and operational downtime.

Analyzing Material Handling Dynamics: How Load Distribution Affects Hydraulic Cylinder Choice

When selecting the appropriate hydraulic cylinder for a forklift, understanding how load distribution impacts cylinder choice is critical. The performance of a hydraulic system is heavily influenced by the weight and positioning of the load being handled. An unbalanced load can strain the hydraulic components, leading to inefficiencies and potential failures. Therefore, it is essential to analyze how loads are distributed during operation, particularly in applications like scrap metal handling where variations in load weight and shape are common.

For instance, equipment designed for material handling, such as the latest models, offers increased versatility to manage diverse loads efficiently. By customizing the hydraulic cylinder specifications according to the expected load distribution, operators can ensure a reliable lifting operation. This approach minimizes the risk of damage to both the forklift and the cargo, ensuring that the productivity and safety of material handling tasks are prioritized. Understanding these dynamics ultimately leads to better decision-making when it comes to upgrading or maintaining hydraulic systems in material handling environments.

Load Capacity vs. Hydraulic Cylinder Size for Forklifts

Regulatory Standards and Best Practices for Hydraulic Cylinder Sizing in Forklift Applications

When selecting hydraulic cylinders for forklift applications, it is essential to consider regulatory standards and best practices to ensure safety and efficiency. The proper sizing of hydraulic cylinders directly influences the forklifts' load capacity and operational performance. Adhering to regulatory standards not only helps in avoiding legal complications but also ensures that the equipment operates within safe limits, contributing to the overall reliability and longevity of the forklift. Industries must keep abreast of any updates in regulations that may affect hydraulic systems and their maintenance.

Best practices emphasize conducting thorough assessments of the specific load requirements and environmental conditions in which the forklift operates. For example, understanding the weight distribution during operations and incorporating adequate safety margins into the hydraulic cylinder design can prevent failures and enhance performance. Additionally, ongoing maintenance and inspections conforming to recognized standards play a critical role in ensuring that the hydraulic systems operate efficiently and safely over time. As industries evolve, staying informed about technological advancements and integrating them into hydraulic cylinder selection processes can lead to improved safety and productivity in forklift operations.

How to Choose the Right Hydraulic Cylinder for Your Forklift Needs Based on Load Capacity

| Load Capacity (lbs) | Cylinder Diameter (inches) | Stroke Length (inches) | Max Pressure (psi) | Weight (lbs) |

|---|---|---|---|---|

| 3,000 | 3.0 | 16 | 2,500 | 45 |

| 5,000 | 4.0 | 20 | 3,000 | 60 |

| 10,000 | 5.0 | 24 | 3,500 | 90 |

| 15,000 | 6.0 | 28 | 4,000 | 120 |

Related Posts

-

Understanding the Functionality of Excavator Hydraulic Cylinders

-

5 Reasons Why Our Best Excavator Hydraulic Cylinder Outperforms Competitors

-

A Comprehensive Guide to Selecting the Best Hydraulic Cylinder for Your Trailer Needs

-

Ultimate Guide to Choosing the Right Hydraulic Cylinder for Excavators with Key Specs and Tips

-

7 Solid Reasons to Choose Hydraulic Oil Cylinders for Your Industrial Needs

-

Ultimate Guide to Understanding Hydraulic Cylinders for Excavators in Global Markets