Top Tips for Choosing the Right Excavator Hydraulic Cylinder for Your Needs

When it comes to selecting the perfect Excavator Hydraulic Cylinder, the decision can significantly impact the efficiency and performance of your excavation tasks. Hydraulic cylinders play a crucial role in providing the necessary power and movement for excavators, making it essential to choose one that aligns with your specific needs. With a diverse range of options available, understanding the key factors that affect your choice will equip you with the knowledge to make an informed decision.

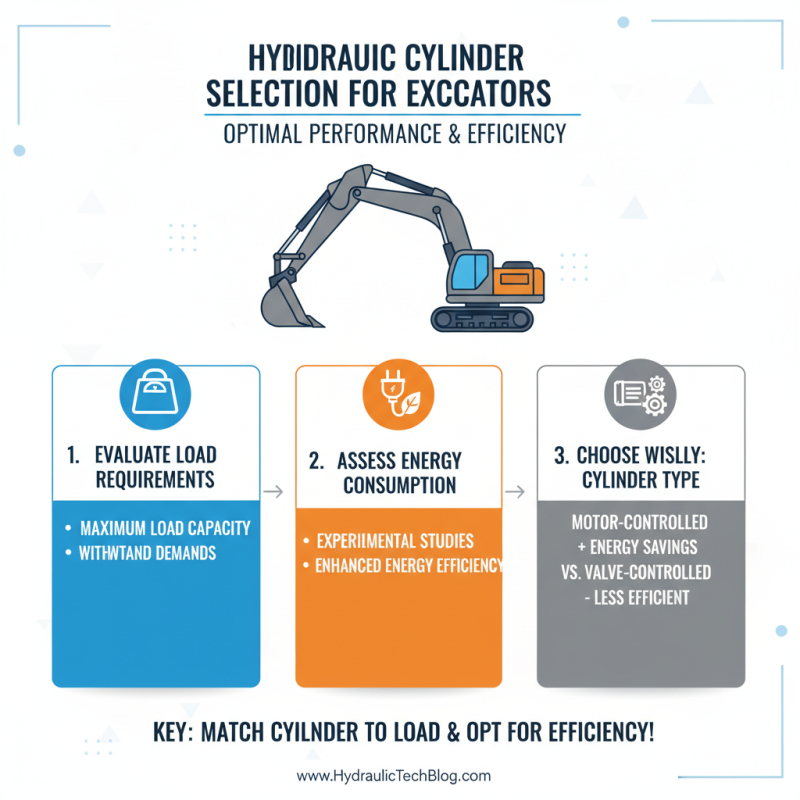

In this guide, we will explore top tips for choosing the right Excavator Hydraulic Cylinder, considering crucial aspects such as load capacity, operating pressure, and compatibility with your machinery. Additionally, we will discuss how different applications may require unique specifications, underscoring the importance of matching the right cylinder to your operational requirements. By following these guidelines, you can ensure optimal performance and longevity of your excavator, ultimately enhancing productivity on the job site.

Understanding the Purpose of Excavator Hydraulic Cylinders

Excavator hydraulic cylinders play a crucial role in the overall functionality of excavators, acting as the powerhouse behind their various movements. These cylinders convert hydraulic energy into mechanical force, enabling the machine to lift, lower, and extend its attachments with precision. Understanding the specific purpose of each hydraulic cylinder is key to selecting the right one for your needs. Typically, these cylinders are categorized based on their placement and function—such as boom cylinders, arm cylinders, and bucket cylinders—each contributing unique capabilities to the excavator's operational tasks.

Choosing the right hydraulic cylinder requires a grasp of your excavator's operational demands and the environments in which it will be used. Factors such as the weight of the loads, the range of motion required, and the hydraulic pressure ratings are critical to ensure optimal performance. Additionally, compatibility with the excavator's hydraulic system cannot be overlooked, as mismatches can lead to inefficiencies and potential damage. By thoroughly assessing these elements, operators can ensure they select a hydraulic cylinder that not only meets their immediate operational needs but also contributes to the longevity and reliability of their equipment.

Identifying Different Types of Hydraulic Cylinders for Excavators

When selecting hydraulic cylinders for excavators, it’s crucial to understand the different types available and their specific applications. There are primarily two types of hydraulic cylinders: single-acting and double-acting cylinders. Single-acting cylinders utilize hydraulic pressure in one direction, making them ideal for operations that require movement in one direction, such as lifting. In contrast, double-acting cylinders can exert force in both directions, providing more versatility and control for tasks like digging and grading.

**Tip:** Always consider the operational requirements of your excavator when choosing a hydraulic cylinder. Factors such as the expected load, working environment, and movement speed should dictate your choice. Matching the cylinder design with your application will enhance efficiency and reduce wear and tear.

Another important type is the telescopic cylinder, which allows for an extended reach without the need for longer excavation equipment. These are particularly beneficial in tight construction sites where space is limited.

**Tip:** Pay attention to the materials used in the hydraulic cylinders. Durable materials, like hardened steel, can significantly improve the lifespan of the cylinder and reduce maintenance costs. Choosing a cylinder with proper seals and protection against hydraulic fluid leaks is also essential to ensure optimal performance.

Top Tips for Choosing the Right Excavator Hydraulic Cylinder for Your Needs

| Cylinder Type | Typical Applications | Bore Size (inches) | Stroke Length (inches) | Max Operating Pressure (psi) |

|---|---|---|---|---|

| Single Acting Cylinder | Lifting and lowering applications | 2.5 | 10 | 2,000 |

| Double Acting Cylinder | Excavating and digging | 4 | 24 | 3,000 |

| Telescopic Cylinder | Reaching and high lift | 6 | 36 | 2,500 |

| Rotary Cylinder | Augering and drilling | 3 | 20 | 2,800 |

Evaluating Load Requirements for Your Excavator's Hydraulic Cylinder

When selecting the right hydraulic cylinder for your excavator, evaluating load requirements is a critical step to ensure optimal performance. Start by assessing the maximum load weight your excavator will often handle. This information forms the foundation for choosing a hydraulic cylinder that can withstand these demands without compromising efficiency. Recent experimental studies highlight the importance of energy consumption assessment in hydraulic systems. Opting for motor-controlled cylinders can significantly enhance energy efficiency compared to traditional valve-controlled options, particularly in heavy lifting operations.

Additionally, consider the working geometry of your excavator alongside load requirements. The hydraulic cylinder must be appropriately sized to accommodate the range of motion and forces produced during operation. Another essential tip is to analyze any past operational failures, such as those documented in studies of discharge boom suspensions in bucket wheel excavators. By understanding root causes of past issues, you can choose a cylinder designed to prevent similar problems and improve reliability. Investing time in evaluating these factors will ultimately lead to more efficient and effective excavator operations.

Assessing Compatibility with Your Excavator Model and Specifications

When selecting a hydraulic cylinder for your excavator, one of the foremost considerations is ensuring compatibility with your specific excavator model and its specifications. Different excavator models come with unique requirements regarding cylinder dimensions, pressure ratings, and mounting configurations. It is essential to gather detailed specifications from your excavator's manual or manufacturer to determine the exact hydraulic cylinder sizes and types needed. This step will not only prevent mismatches but also ensure optimal performance and safety during operation.

Furthermore, pay attention to the hydraulic system's pressure capabilities and flow rates. Cylinders designed for different pressure ranges may not function effectively, potentially leading to breakdowns or inefficient operation. Always verify that the new hydraulic cylinder's ratings align with your excavator's hydraulic system specifications. Consulting with manufacturers or suppliers can provide additional insights and recommendations tailored to your excavator model, ensuring that you select the right hydraulic cylinder for your operational needs. By prioritizing compatibility, you'll enhance the longevity and reliability of your excavator while reducing the risk of costly repairs down the line.

Excavator Hydraulic Cylinder Size Compatibility

Material and Design Considerations for Hydraulic Cylinder Longevity

When selecting an excavator hydraulic cylinder, understanding the material and design considerations is crucial for ensuring longevity and optimal performance. The material used in the construction of the hydraulic cylinder plays a significant role in its durability. High-strength steel is often preferred due to its ability to withstand harsh working conditions and resist wear. Additionally, consider cylinders that feature corrosion-resistant coatings to enhance their lifespan, especially when working in wet or abrasive environments.

Another essential aspect is the design of the hydraulic cylinder itself. Look for cylinders with a proper sealing system that prevents leakage and minimizes contamination. A well-designed hydraulic cylinder will facilitate smoother operation and reduce the risk of unexpected failures.

Tip: Always consult with manufacturers about the specific working conditions and load requirements for your excavator.

Tip: Regularly maintaining your hydraulic equipment, including routine inspections, ensures any wear or damage is addressed before it becomes a major issue.

Investing time in understanding these material and design considerations will ultimately lead to a more reliable and efficient hydraulics system for your excavator, minimizing downtime and repair costs.

Related Posts

-

Understanding the Best Hydraulic Oil Cylinder Types for Your Needs

-

5 Reasons Why Our Best Excavator Hydraulic Cylinder Outperforms Competitors

-

7 Essential Tips to Maximize Efficiency with Hydraulic Oil Cylinders: Improve Performance by 30%!

-

Innovative Solutions for Hydraulic Cylinder For Excavator Enhancing Performance and Longevity

-

Maximizing Efficiency: The Advantages of Upgrading Your Hydraulic Oil Cylinder Systems

-

How to Choose the Best Hydraulic Cylinder for Your Trailer Needs