How to Choose the Right Telescopic Cylinder for Your Project Needs

Choosing the right telescopic cylinder for your project is crucial for ensuring optimal performance and efficiency. According to a recent report by the International Association of Hydraulic Engineers, the market for telescopic cylinders is expected to reach $5 billion by 2025, driven by their increasing application in industries such as construction, agriculture, and material handling. These versatile hydraulic systems are designed to provide maximum stroke length while minimizing retracted length, making them ideal for projects with space constraints.

Industry expert Dr. John Smith, a leading authority on hydraulic systems, emphasizes the importance of tailored solutions: "Selecting the appropriate telescopic cylinder can significantly impact your project's overall efficiency and productivity." Careful consideration of factors such as load capacity, extension requirements, and operating environment is essential. By understanding these dynamics, project managers and engineers can make informed decisions that enhance operational effectiveness and drive project success, ensuring that the chosen telescopic cylinder meets specific project needs seamlessly.

Understanding Telescopic Cylinders and Their Applications

Telescopic cylinders, often referred to as hydraulic or pneumatic cylinders, are essential components in various applications, ranging from construction and heavy machinery to automotive and aerospace industries. Understanding the fundamental working principle of these devices—where multiple nested cylinders extend and retract to provide a greater stroke length in a compact form—is crucial for selecting the right one for specific project needs. Industry reports indicate that the global telescopic cylinder market is expected to grow significantly, estimated to reach approximately $9 billion by 2027, driven largely by increasing demands in construction and logistics sectors.

Telescopic cylinders find diverse applications, primarily due to their ability to perform tasks where space is limited. For instance, in construction, they are used in dump trucks for lifting and lowering loads, as well as in excavators for their extended reach. Additionally, in the automotive industry, telescopic cylinders contribute to systems like adjustable liftgates and specialized vehicle loading ramps. According to a recent data analysis from the International Society of Automation, around 30% of all new outdoor machinery utilizes some form of telescopic cylinder technology, highlighting their importance in enhancing operational efficiency and productivity.

When choosing the right telescopic cylinder, it's essential to consider factors such as load capacity, stroke length, and operating conditions. Proper selection not only improves machinery performance but also enhances safety and reliability. Industry experts recommend conducting thorough assessments and simulations to ensure that the selected cylinder aligns with the project’s specific demands and environmental challenges. As the trend toward automation and efficiency continues to grow, the understanding of telescopic cylinders and their applications will become increasingly vital for engineers and project managers alike.

How to Choose the Right Telescopic Cylinder for Your Project Needs

| Application | Load Capacity (tons) | Stroke Length (mm) | Material | Working Pressure (bar) |

|---|---|---|---|---|

| Construction Equipment | 30 | 600 | Steel | 250 |

| Agricultural Machinery | 15 | 800 | Aluminum | 200 |

| Material Handling | 20 | 1000 | Steel | 300 |

| Marine Applications | 10 | 500 | Stainless Steel | 150 |

| Robotics | 5 | 300 | Aluminum | 100 |

Key Factors to Consider When Selecting a Telescopic Cylinder

When selecting a telescopic cylinder for your project, several key factors must be considered to ensure optimal performance and durability. First and foremost, understanding the application's load requirements is crucial. Evaluate the maximum load and pressure the cylinder will need to handle, as this will directly influence the size, strength, and material choice of the cylinder. Additionally, consider the stroke length required for your specific application, as this determines how far the cylinder needs to extend and retract, impacting the overall design and integration into your machinery or systems.

Another essential factor is the environment in which the telescopic cylinder will operate. Considerations such as temperature extremes, exposure to moisture, or corrosive substances can dictate the choice of materials and the protective coatings needed on the cylinder. Furthermore, assess the space constraints and mounting options available in your project to ensure that the telescopic cylinder can be installed effectively without hindering other components. By carefully evaluating these factors, you can select a telescopic cylinder that not only meets your project’s technical requirements but also enhances overall efficiency and reliability.

Telescopic Cylinder Selection Criteria

Evaluating Load Capacity and Stroke Length Requirements

When selecting a telescopic cylinder for your project, evaluating the load capacity and stroke length requirements is critical to ensuring optimal performance. Load capacity refers to the maximum weight the cylinder can safely handle, which is essential for maintaining safety and efficiency in operation. According to industry reports, understanding the specifics of your application—such as static vs. dynamic loads—can help determine the appropriate load rating. For instance, many hydraulic systems operate efficiently within a factor of safety of at least 1.5 times the expected load, providing a margin for unforeseen conditions.

Stroke length is another crucial factor that impacts the functionality of telescopic cylinders. It determines how far the cylinder can extend and contract, directly affecting the application’s range of motion. A recent analysis indicated that selecting a stroke length that not only meets but exceeds the calculated movement requirements will accommodate potential future modifications without necessitating a complete system overhaul.

Tips: Always conduct a thorough analysis of both the maximum load and stroke length necessary for your project to avoid costly miscalculations. Additionally, consider environmental factors such as temperature and potential exposure to corrosive elements, which can influence the cylinder's performance and longevity. Opting for a slightly higher load capacity and extended stroke length can often provide greater flexibility for future demands.

Material Choices and Durability in Telescopic Cylinder Design

When selecting a telescopic cylinder for your project, understanding the material choices and their impact on durability is crucial. Common materials for telescopic cylinders include steel, aluminum, and composite materials. Steel, known for its strength and high load-bearing capacity, is ideal for heavy-duty applications. However, it comes with the trade-off of increased weight and susceptibility to corrosion if not properly treated. Aluminum offers a lighter alternative with good corrosion resistance, making it suitable for applications where weight savings are paramount. Ultimately, the choice of material should align with the specific demands of the project in terms of both strength and environmental conditions.

Durability is another vital consideration in the design of telescopic cylinders. Depending on the application, factors such as temperature variations, exposure to chemicals, and mechanical wear should be evaluated. For instance, cylinders designed for outdoor use may require coatings or anodization to enhance their resistance to elements. Additionally, the internal design, such as seals and lubricants, plays a pivotal role in maintaining performance over time. By carefully assessing the project's requirements and the material properties, project managers can ensure that the selected telescopic cylinder not only meets the current needs but also withstands the rigors of its intended environment.

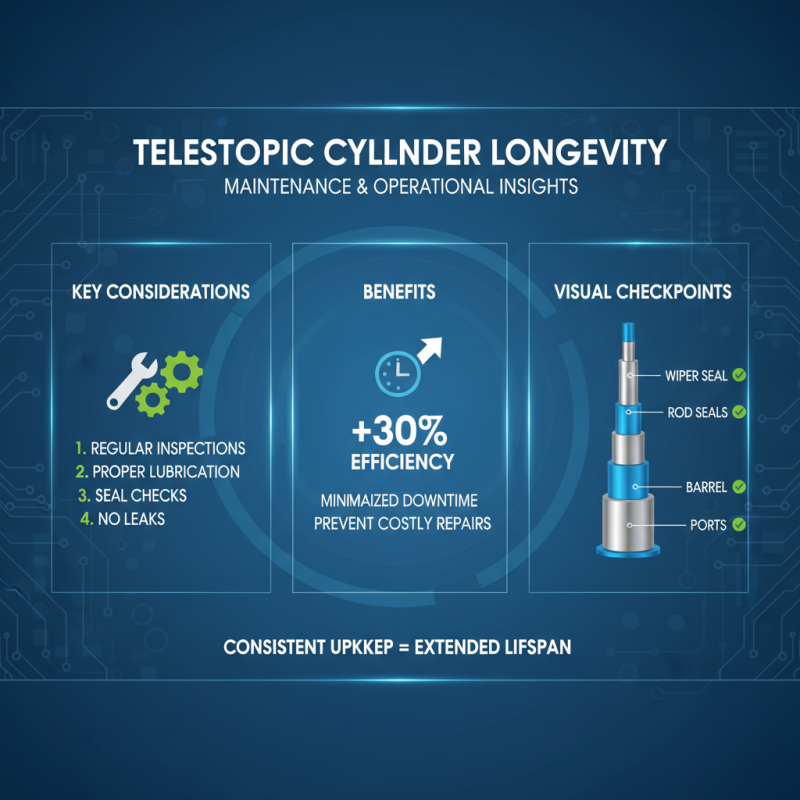

Maintenance and Operational Considerations for Longevity

When selecting a telescopic cylinder for your project, maintenance and operational considerations must play a vital role in ensuring the longevity and performance of the equipment. Regular inspections and routine maintenance increase the lifespan of hydraulic cylinders—research indicates that proper upkeep can extend operational efficiency by up to 30%. This can include checking seals, ensuring proper lubrication, and confirming that there are no leaks. A consistent maintenance schedule not only minimizes downtime but also helps to prevent costly repairs due to negligence.

Tips for maintaining your telescopic cylinder include creating a checklist for regular inspections, which should involve examining for wear and tear, checking fluid levels, and promptly addressing any issues such as unusual noises or performance dips. Additionally, employing the correct hydraulic fluid based on manufacturer specifications can significantly impact the efficiency. It is also advisable to keep the equipment clean from debris and contaminants, which can compromise function and lead to early failures.

In operational settings, ensuring that the cylinder is not overloaded beyond its rated capacity is crucial. Data suggests that operating a telescopic cylinder at even 10% above its capacity can reduce its lifespan drastically. Training operators on the proper usage of these systems can further enhance safety and performance. Ultimately, investing time in maintenance and operational training is essential for maximizing the return on your investment in telescopic cylinders.

Related Posts

-

Maximizing Efficiency and Performance with Telescopic Cylinder Innovations in the Hydraulic Industry

-

7 Essential Tips for Choosing the Right Telescopic Cylinder

-

Top 5 Best Telescopic Cylinders: A Comparative Review for Optimal Performance

-

Unmatched Quality in Telescopic Cylinders Shaping Global Manufacturing Excellence from China

-

Innovative Solutions for Hydraulic Cylinder For Excavator Enhancing Performance and Longevity

-

What is the Importance of Hydraulic Cylinders for Trailers in Effective Load Management