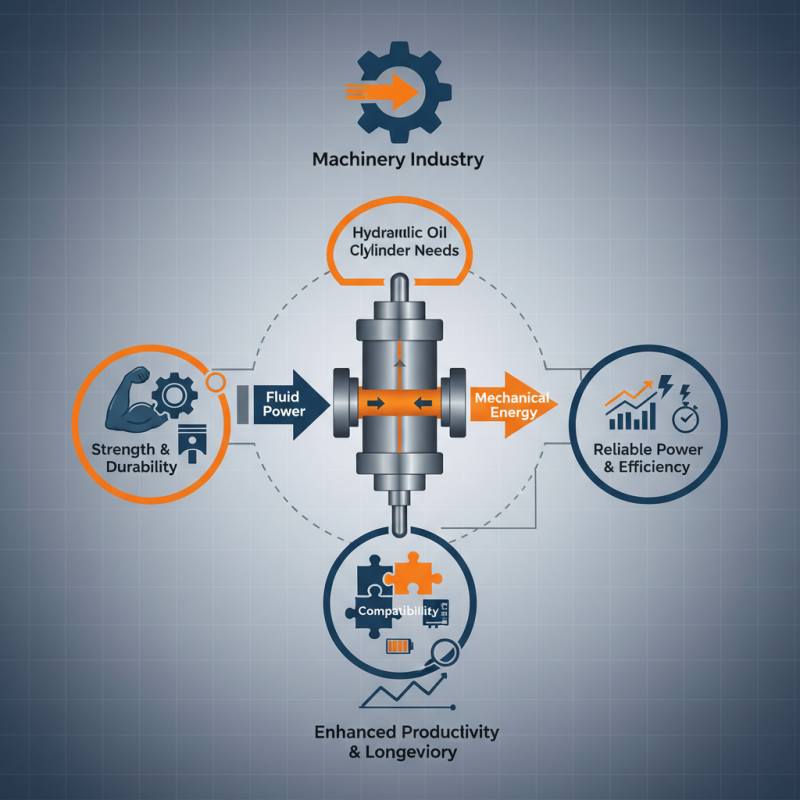

Why Choose Hydraulic Oil Cylinder for Your Machinery Needs?

In the machinery industry, selecting the right components is crucial. Hydraulic oil cylinders are essential for many applications. They provide reliable power and efficiency. According to Dr. John Masters, a leading expert in hydraulics, "The choice of hydraulic oil cylinder can make or break your equipment's performance." This highlights the importance of careful selection.

Hydraulic oil cylinders are known for their strength and durability. They transform fluid power into mechanical energy. This process is vital for heavy machinery operations. However, not every cylinder suits every application. It’s essential to assess compatibility with existing systems. Failing to do so can lead to inefficiencies.

Some may overlook these details. Trusting a generic solution can be tempting. Yet, specific machinery demands tailored answers. Investing time in research can prevent future issues. Ultimately, the right hydraulic oil cylinder enhances productivity and ensures longevity. Choosing wisely pays off in improved performance and reliability.

Advantages of Using Hydraulic Oil Cylinders in Machinery

Hydraulic oil cylinders offer numerous advantages for machinery applications. One major benefit is efficiency. According to a report by the International Energy Agency, hydraulic systems can achieve up to 95% energy efficiency. This efficiency translates into lower operational costs and reduced environmental impact. Engineers often prefer these cylinders because they provide precise control over pressure and speed.

Durability is another key advantage. Hydraulic oil cylinders can withstand harsh conditions, including extreme temperatures and heavy loads. Studies show that hydraulic systems often have a lifespan of over 10,000 hours with proper maintenance. However, it's essential to monitor for leaks and wear, as these can significantly diminish performance.

The versatility of hydraulic cylinders also deserves mention. They can be used in various applications, from construction equipment to manufacturing machines. However, challenges remain. Hydraulic oil contamination can lead to failure if not addressed. Regular maintenance is needed to ensure optimal performance. Investing in high-quality hydraulic systems may yield significant returns in productivity and reliability.

Key Components of Hydraulic Oil Cylinders Explained

Hydraulic oil cylinders are essential for multiple machinery applications. They convert hydraulic energy into mechanical energy. Understanding their key components is crucial for effective usage.

Hydraulic accumulators play a significant role as well. They store energy and maintain pressure. According to industry reports, using accumulators can improve system responsiveness by up to 40%. However, selecting the right size and type requires careful thought. Miscalculations lead to system failures. Costs can escalate if the wrong decisions are made. Each component works together, highlighting the need for thorough knowledge in hydraulics. Understanding these fundamentals can enhance performance and reduce downtime.

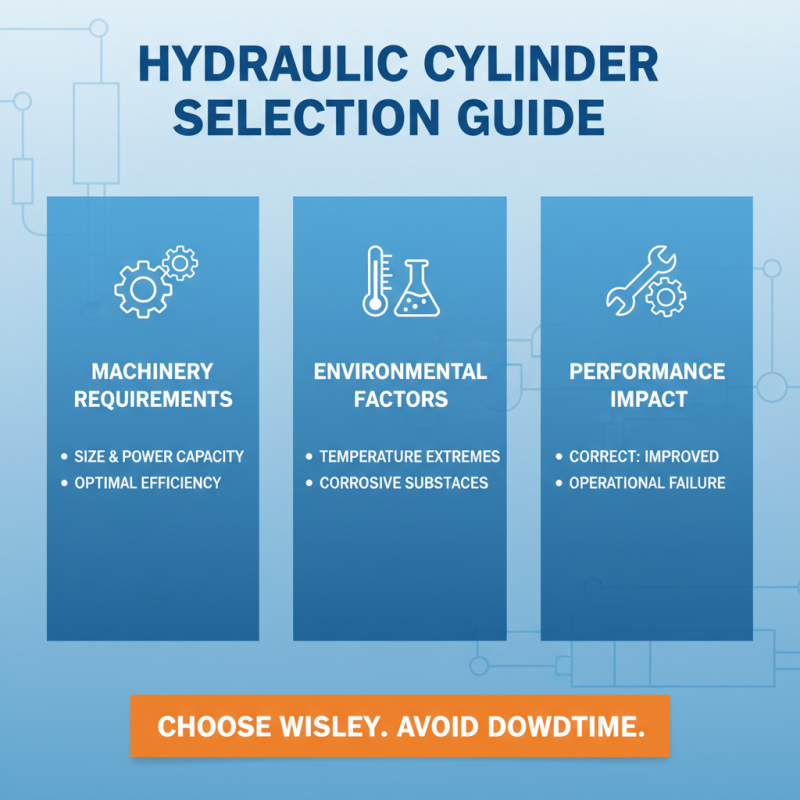

Factors to Consider When Choosing Hydraulic Oil Cylinders

When selecting hydraulic oil cylinders, understanding the specific requirements of your machinery is crucial. Size and power capacity are key factors. A correct cylinder can improve efficiency; an incorrect one can lead to operational failure. Consider the working environment too. Extreme temperatures or corrosive substances can impact performance.

Tips: Always check compatibility with existing machinery. Regular maintenance is essential, but preventive measures can save costs later.

Material choice matters greatly. Steel and aluminum are common, each with pros and cons. Steel offers strength but adds weight. Aluminum is lighter but may not withstand heavy loads as well. Make sure you evaluate the trade-offs based on usage patterns.

Don't overlook the importance of seals and fittings. A poor seal can lead to leaks. Choosing the best seal type based on fluid compatibility can improve the cylinder's lifespan. Leaks often indicate wear or poor installation, so frequent checks are advised.

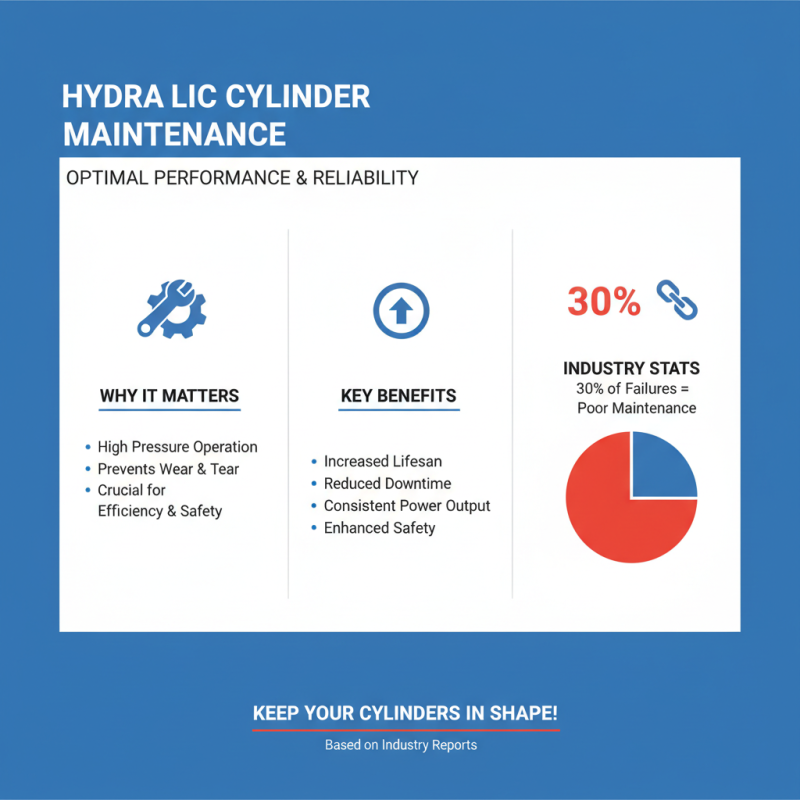

Maintenance Tips for Optimal Performance of Hydraulic Oil Cylinders

Regular maintenance of hydraulic oil cylinders ensures optimal performance. These cylinders operate under high pressure, which can lead to wear and tear if not properly managed. According to industry reports, about 30% of hydraulic system failures are linked to poor maintenance. Keeping your cylinders in good shape is crucial for efficiency and safety.

One essential tip is to regularly check the fluid levels. Low hydraulic fluid can cause overheating and system breakdowns. Inspect seals and hoses for any signs of wear. Small leaks can lead to significant issues over time. Aim for a fluid change every 1,000 hours of operation to maintain efficiency.

Another vital aspect is keeping the system clean. Contaminants can cause damage to the cylinder internals. Consider using filters to minimize risk. According to studies, contaminants can reduce the lifespan of hydraulic components by up to 70%. Implementing a routine cleaning schedule can help extend the life of your equipment. Don't overlook these details; they make all the difference.

Applications of Hydraulic Oil Cylinders in Various Industries

Hydraulic oil cylinders are crucial in various industries. They offer force and precision for diverse applications. According to a recent industry report, the global hydraulic cylinder market is projected to reach $15 billion by 2026. This growth reflects their importance in sectors like construction, automotive, and aerospace.

In construction, hydraulic cylinders power heavy machinery. They lift, push, and pull massive loads with accuracy. A study noted that around 70% of construction equipment uses these cylinders. Their reliability is essential for safety and efficiency. However, maintenance can be overlooked. Neglecting regular checks may lead to malfunctions. These issues can result in significant downtime.

The automotive industry also relies heavily on hydraulic systems. These systems control braking and suspension functions. A key statistic reveals that hydraulic cylinders enhance vehicle safety by improving response times. Yet, some companies struggle with the integration of newer technology. Resistance to change can hinder progress in innovation and efficiency. Embracing modern solutions could greatly enhance operational success.

Applications of Hydraulic Oil Cylinders in Various Industries

| Industry | Application | Specifications | Benefits |

|---|---|---|---|

| Construction | Excavators and Loaders | Pressures up to 3000 PSI | High lifting capabilities, robust design |

| Manufacturing | Stamping and Pressing Machines | Precision of ±0.01 mm | Consistency and accuracy in production |

| Agriculture | Tractors and Harvesters | Power ratings of 20-50 HP | Increased efficiency and productivity |

| Transportation | Buses and Trucks | Operating temperatures up to 200°F | Enhanced stability and control |

| Mining | Drilling and Excavation Equipment | Capacity of 500 tons | Durability in harsh environments |

Related Posts

-

Essential Checklist for Selecting the Right Hydraulic Oil Cylinder for Your Needs

-

Ultimate Guide to Choosing the Best Hydraulic Oil Cylinder for Your Needs

-

Top Strategies for Enhancing Performance of Hydraulic Oil Cylinders

-

What is a Hydraulic Oil Cylinder and How Does it Work?

-

A Comprehensive Guide to Selecting the Best Hydraulic Cylinder for Your Trailer Needs

-

Ultimate Checklist for Choosing the Right Hydraulic Cylinder for Your Forklift