Top 10 Benefits of Using an Excavator Hydraulic Cylinder in Construction?

In the construction industry, the role of the excavator hydraulic cylinder is often understated. According to John Smith, a hydraulic systems expert, "The efficiency of construction projects significantly hinges on the performance of the excavator hydraulic cylinder." This vital component enhances the machine’s power and precision, allowing operators to complete tasks with greater speed and accuracy.

Excavator hydraulic cylinders are essential for various applications. They provide the necessary force to lift heavy materials, dig deep trenches, and demolish structures effectively. The enhanced control over operations can transform a project’s timeline positively. However, it’s crucial to recognize that improper maintenance can lead to costly downtime and repairs.

Not every operator fully understands the potential of an excavator hydraulic cylinder. Limited training can result in mishandling of equipment. Mistakes may lead to accidents or inefficiencies on job sites. Continuous education and practical experience can mitigate these issues, ensuring operators leverage the full potential of this powerful tool.

Benefits of Enhanced Lifting Power in Excavator Hydraulic Cylinders

Excavator hydraulic cylinders play a crucial role in enhancing lifting power on construction sites. The efficiency of these cylinders can greatly impact overall project success. Reports indicate that hydraulic systems can lift up to 80% more weight than mechanical systems. This ability is vital when moving heavy materials, allowing for faster project completion.

In construction, the right lifting power is essential. A hydraulic cylinder can provide precise control over heavy loads. This precision minimizes the risk of accidents. Enhanced control helps operators align loads accurately and navigate tight spaces. However, operators should be aware of the potential for hydraulic leaks. Regular maintenance checks are necessary to prevent these issues.

Tips: Always inspect hydraulic cylinders before use. Look for wear and tear. This can prevent unexpected downtime. Operators should also practice safe lifting techniques. Ensuring stability is key to maintaining safety. Remember, while hydraulic cylinders offer great power, they also require responsible handling.

Improved Precision and Control in Construction Tasks

In construction, precision and control are vital. An excavator hydraulic cylinder plays a crucial role in achieving this. These cylinders provide smooth lifting and lowering motions. They allow operators to handle materials with accuracy. This results in less waste and improved project outcomes.

When using hydraulic cylinders, workers can complete tasks more efficiently. Adjustments can be made quickly, enhancing control over movements. This ability to fine-tune operations can significantly reduce errors. However, without proper training, operators may struggle with these adjustments. Understanding the equipment is essential to maximize its benefits.

Moreover, precise control can impact the workflow. In busy construction sites, time management is crucial. Any delay can cascade into larger issues. Improper use of the hydraulic system may lead to accidents or injuries. This highlights the need for continuous training and safety measures. Overall, focusing on precision in using excavator hydraulic cylinders can profoundly affect project success.

Top 10 Benefits of Using an Excavator Hydraulic Cylinder in Construction

| Benefit | Description | Impact on Construction |

|---|---|---|

| Improved Precision | Hydraulic cylinders provide better control of movements, allowing for more accurate positioning. | Enhances the quality of work, reducing mistakes in excavation tasks. |

| Increased Efficiency | Speed up tasks such as digging and lifting with powerful hydraulic force. | Saves time and labor costs during construction projects. |

| Enhanced Control | Allows operators to fine-tune movements for better differentiation in tasks. | Facilitates complex operations such as grading and leveling. |

| Versatility | Can be used for various attachments and functions, enhancing task capabilities. | Expands the range of operations without needing multiple machines. |

| Safety | Hydraulic systems are generally more stable, reducing the likelihood of accidents. | Increases job site safety and decreases the risk of operator error. |

| Load Handling | Can manage heavy loads efficiently, reducing physical stress on operators. | Improves productivity in lifting and relocating materials. |

| Reliability | Hydraulic systems are known for their durability and consistent performance. | Ensures minimal downtime, keeping projects on schedule. |

| Adaptability | Easily adjustable for different tasks, enhancing operational flexibility. | Allows adaption to changing project requirements without extra costs. |

| Cost-Effectiveness | Despite higher initial costs, they provide long-term savings through efficiency and reduced labor. | Brings a high return on investment over time. |

Increased Efficiency and Productivity for Construction Projects

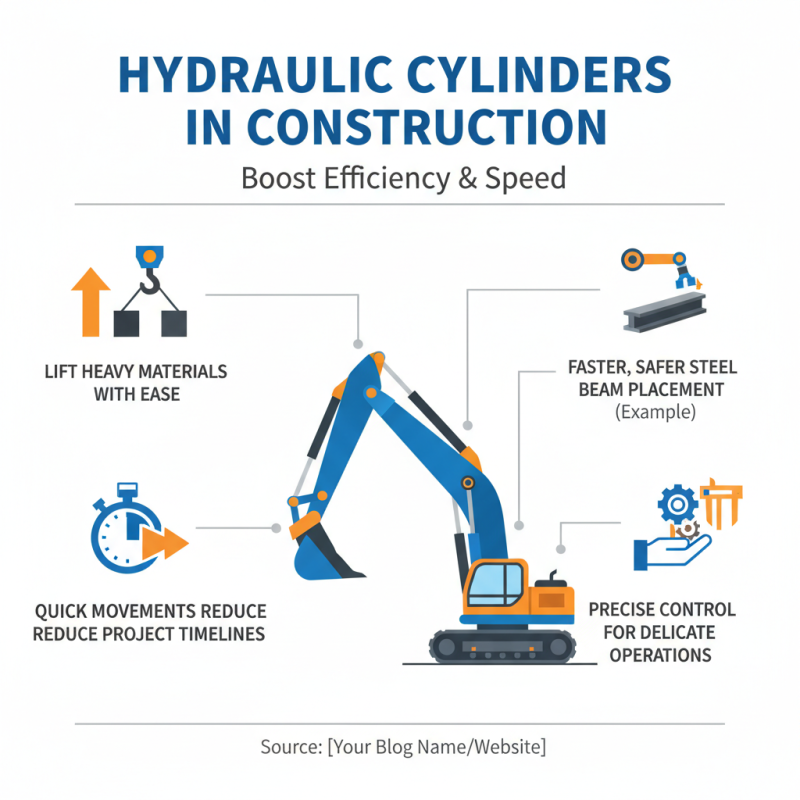

In the construction industry, hydraulic cylinders play a crucial role in enhancing efficiency. These powerful components lift heavy materials with ease. They enable quick movements, reducing project timelines significantly. For example, moving large steel beams becomes faster and safer. The precise control offered by hydraulic systems allows for delicate operations too.

One notable advantage is the adaptability of hydraulic cylinders. They can be fitted to various machinery, from excavators to backhoes. This versatility can minimize the need for multiple machines on-site. Workers can switch tasks swiftly, which may lead to a seamless workflow. However, operators must receive proper training. Misuse can lead to accidents, underscoring the importance of safety protocols.

Despite their benefits, challenges exist in maintaining hydraulic cylinders. Regular inspections and repairs are vital. Neglecting these can lead to costly failures. It’s essential for teams to stay proactive. Investing in preventive maintenance ensures that projects run without unexpected delays. Such awareness can ultimately improve project outcomes and team morale.

Durability and Reliability in Harsh Work Environments

In the construction industry, hydraulic cylinders play a crucial role in maximizing performance. Their durability and reliability in harsh work environments are key benefits. According to industry reports, hydraulic cylinders can withstand extreme temperatures, ranging from -20°F to 185°F. This ability ensures consistent function, even in challenging conditions.

Hydraulic systems can face a range of pressures. A typical excavator cylinder operates between 2,000 and 3,000 psi. This robust capacity allows for heavy lifting and precise movements, enhancing productivity. However, wear and tear are inevitable. Routine inspections and maintenance are essential to identify issues early. Operators should monitor fluid levels and check seals frequently.

Tips: Keep a journal of maintenance activities. Track any unusual signs. Early detection can save money and time.

Furthermore, the risk of cylinder failure exists, particularly under heavy workloads. Maintaining a proper load limit is vital. Engineers often recommend not exceeding 90% of the maximum capacity. Awareness of this can prevent accidents and equipment damage. Regular training on hydraulic systems for operators is beneficial. It promotes safe and efficient usage.

Tips: Invest in operator training. A well-trained team is your best asset. Minimizing human error boosts overall safety.

Versatility in Multiple Construction Applications and Tasks

Excavator hydraulic cylinders are essential tools in construction. Their versatility enables them to excel in numerous applications. From digging and lifting to breaking and grading, these cylinders enhance efficiency in various tasks.

When using an excavator hydraulic cylinder, consider the type of job at hand. Certain tasks may demand different cylinder sizes or capabilities. Always assess the weight and conditions of the materials involved. This evaluation can prevent accidents and improve performance.

Another tip is to maintain your equipment regularly. A well-maintained hydraulic cylinder promises smoother operation. Neglecting this can lead to unexpected failures and costly repairs. Operators should also be trained adequately to handle these machines effectively. Their skills directly impact safety and project timelines.

Related Posts

-

Ultimate Guide to Understanding Hydraulic Cylinders for Excavators in Global Markets

-

7 Solid Reasons to Choose Hydraulic Oil Cylinders for Your Industrial Needs

-

5 Reasons Why Our Best Excavator Hydraulic Cylinder Outperforms Competitors

-

Understanding the Best Hydraulic Oil Cylinder Types for Your Needs

-

The Ultimate Guide to Choosing the Right Hydraulic Cylinder for Your Excavator Needs

-

Top Tips for Choosing the Right Excavator Hydraulic Cylinder for Your Needs