2025 Top Insights on Telescopic Cylinders Underbody Technology and Applications

The advancements in Telescopic Cylinders Underbody technology have revolutionized numerous applications across various industries, particularly in construction and transportation. As we delve into the insights of 2025, it is crucial to examine how these innovative designs enhance the efficiency and performance of heavy machinery. Telescopic cylinders, known for their compact construction and significant extension capabilities, allow for increased power in limited spaces, making them ideal for underbody applications where space efficiency is paramount.

Furthermore, the versatility of Telescopic Cylinders Underbody systems is evident in their integration into a wide range of mobile equipment. From dump trucks to excavators, these cylinders enable improved payload management and superior operational flexibility. The upcoming trends indicate a growing demand for enhanced durability and performance, driven by technological advancements such as smart sensors and automation. This report will explore the critical insights and emerging applications of telescopic cylinders, shedding light on how they are shaping the future of industrial machinery and contributing to more sustainable operational practices.

Overview of Telescopic Cylinders Underbody Technology in 2025

In 2025, telescopic cylinder underbody technology has evolved significantly, offering innovative solutions across various industries. These advanced cylinders, designed to be compact and extendable, provide enhanced performance and flexibility in applications ranging from construction machinery to automotive systems. The ability to manipulate space effectively allows for improved lifting capacities and greater stability in equipment, addressing the increasing demands for efficiency in modern operations.

The integration of intelligent sensors and automation features has further transformed the functionality of telescopic cylinders. By incorporating real-time data analytics, users can monitor performance metrics and optimize operations, leading to increased safety and reduced downtime. This technological advancement not only streamlines workflows but also supports the development of smarter, more responsive systems that adapt to various operational conditions. As industries continue to prioritize efficiency and reliability, the role of telescopic cylinders underbody technology is likely to expand, paving the way for new applications and innovations in the years to come.

2025 Top Insights on Telescopic Cylinders Underbody Technology and Applications

| Dimension | Value | Application |

|---|---|---|

| Max Stroke Length | 3000 mm | Construction Equipment |

| Operating Pressure | 21 MPa | Material Handling |

| Weight Capacity | 20 Ton | Agriculture |

| Material Used | High Strength Steel | Transport Vehicles |

| Typical Applications | Lifting, Stabilizing | Industrial Machinery |

Key Applications of Telescopic Cylinders in Various Industries

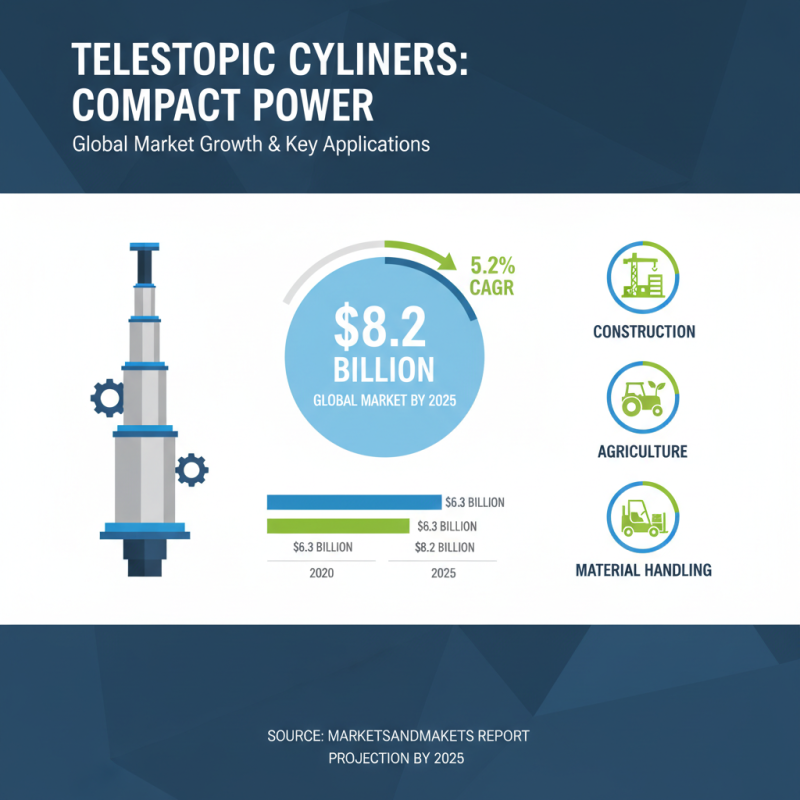

Telescopic cylinders, known for their compact design and impressive lifting capabilities, are increasingly being recognized for their vital role across various industries. According to a report by MarketsandMarkets, the global market for hydraulic cylinders, including telescopic variants, is projected to reach $8.2 billion by 2025, reflecting a compound annual growth rate (CAGR) of around 5.2%. This growth is primarily driven by their applications in sectors such as construction, agriculture, and material handling, where efficient and reliable lifting systems are crucial.

In the construction industry, telescopic cylinders are often employed in cranes and aerial work platforms, providing extended reach while maintaining stability. A study by the Association of Equipment Manufacturers indicates that the use of hydraulic solutions, including telescopic technology, could enhance the efficiency of construction processes by 20-30%. Similarly, in the agricultural sector, these cylinders facilitate operations in tractors and harvesting machinery, allowing for greater precision and productivity while minimizing soil compaction. The American Society of Agricultural and Biological Engineers highlights that integrating advanced hydraulic systems can improve farm machinery performance by up to 15%, significantly impacting yield and operational efficiency.

Moreover, the material handling sector utilizes telescopic cylinders in various applications, including dump trucks and support lifting systems, enabling safe and efficient transfer of goods. According to the Material Handling Industry of America, using telescopic cylinders enhances load handling capabilities, reducing cycle times by approximately 25%. As industries continue to innovate and demand higher efficiency, telescopic cylinders will undoubtedly play an integral role in shaping the future of operational performance across diverse sectors.

Performance Metrics and Efficiency Improvements of Underbody Cylinders

The advancements in telescopic cylinders underbody technology are paving the way for enhanced performance metrics within various applications. These cylinders are designed to deliver significant mechanical advantage while maintaining a compact profile, making them ideal for vehicles subjected to space constraints. A notable aspect is their ability to provide extensive stroke lengths relative to their collapsed size, which leads to improved maneuverability and operational efficiency in various mechanisms, from automotive to industrial machinery.

Efficiency improvements in underbody cylinders are primarily driven by developments in hydraulic systems and materials. Innovations such as lightweight composite materials reduce the overall weight, contributing to lower fuel consumption and enhanced handling characteristics. Furthermore, advanced sealing technology minimizes fluid loss, thereby improving energy efficiency and system reliability. Continuous performance metrics indicate that these enhancements not only boost the operational lifespan of the cylinders but also optimize their responsiveness, providing operators with better control over their machinery and applications. As industries evolve, the importance of such underbody technologies will increasingly manifest in terms of safety, performance, and sustainability.

Performance Metrics and Efficiency Improvements of Underbody Cylinders (2025)

Market Analysis: Trends and Growth Projections for Telescopic Cylinder Technology

The market for telescopic cylinder technology is on the rise, driven by expanding applications across various industries such as construction, agriculture, and transportation. As equipment becomes more complex and demands for efficiency increase, telescopic cylinders offer a unique solution by providing a compact design with an extended reach. This trend reflects a shift towards smarter, more effective machinery that minimizes space requirements while maximizing performance.

Tips: When considering telescopic cylinder technology, it's crucial to evaluate the specific requirements of your application. Focus on the load capacity, extension range, and environmental conditions of use. Additionally, keep an eye on emerging materials and design innovations that could enhance the durability and efficiency of these cylinders.

As the industry progresses towards automation and IoT integration, the growth projections for telescopic cylinder technology look promising. Companies are investing in research and development to improve functionality and reliability. This emphasis on technological advancements is expected to not only increase market share but also enhance overall productivity in operational environments. As you explore options for telescopic cylinders, gauge the potential for interconnected systems that can deliver real-time data and insights, ultimately leading to better decision-making and streamlined processes.

Innovative Developments and Future Prospects in Underbody Cylinder Design

The field of underbody telescopic cylinders has witnessed groundbreaking advancements that enhance both functionality and design. Innovative developments in materials science have led to the use of lightweight yet durable composites, allowing for improved performance under high stress conditions. These materials not only reduce the overall weight of the systems but also enhance their resistance to environmental factors such as corrosion and wear, thus ensuring longer lifespan and reliability in various applications.

Looking ahead, the future prospects for underbody cylinder design are poised to incorporate smart technologies and automation. Integrating sensors and IoT connectivity into these cylinders will enable real-time monitoring and predictive maintenance, further optimizing performance. This shift towards intelligent systems will also facilitate the development of adaptive solutions that can respond to changing load conditions dynamically. As industries continue to emphasize efficiency and sustainability, the evolution of telescopic cylinders promises to align closely with the growing demand for innovative, reliable, and eco-friendly solutions.

Related Posts

-

The Ultimate Guide to Sourcing Telescopic Cylinders Underbody for Global Buyers

-

Ultimate Guide to Mastering Telescopic Cylinders Underbody for Enhanced Performance

-

The Ultimate Guide to Understanding Telescopic Cylinders Underbody Applications and Benefits

-

Exploring Alternative Solutions for Telescopic Cylinders Underbody Applications

-

Essential Tips for Identifying Reliable Manufacturers of Best Telescopic Cylinders Underbody

-

Exploring Market Potential of Telescopic Cylinders Underbody at 2025 China Import and Export Fair